Steam supply passive type direct methanol fuel cell with catalytic combustion type heat supplying

A methanol fuel cell, catalytic combustion technology, applied in fuel cells, fuel cell additives, circuits, etc., can solve the problems of increasing the cost and operation difficulty of the battery, reducing the overall performance of the battery system, and requiring high stability, and achieving increased The effect of large energy utilization rate, improved fuel utilization rate, and stable heat supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

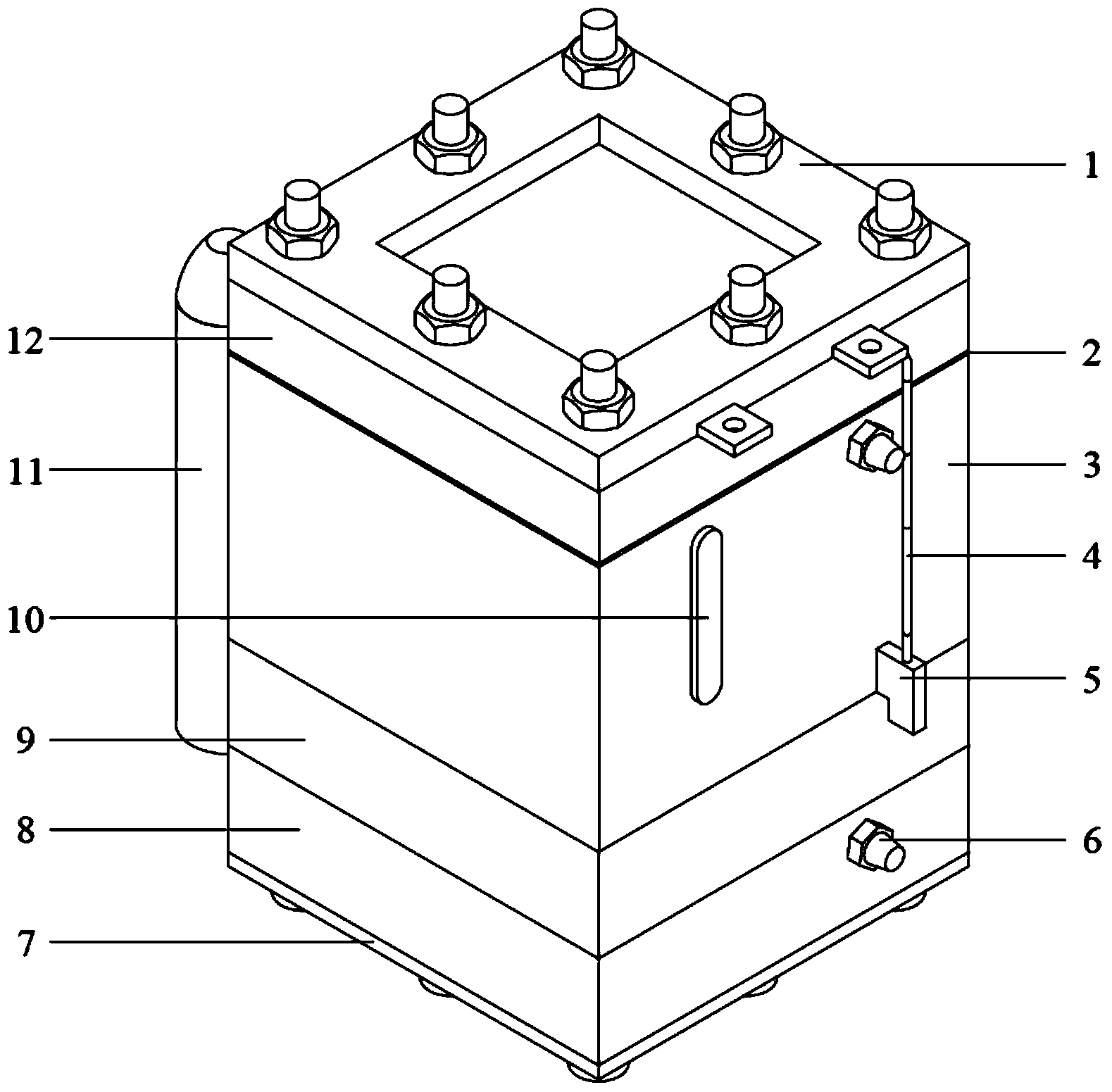

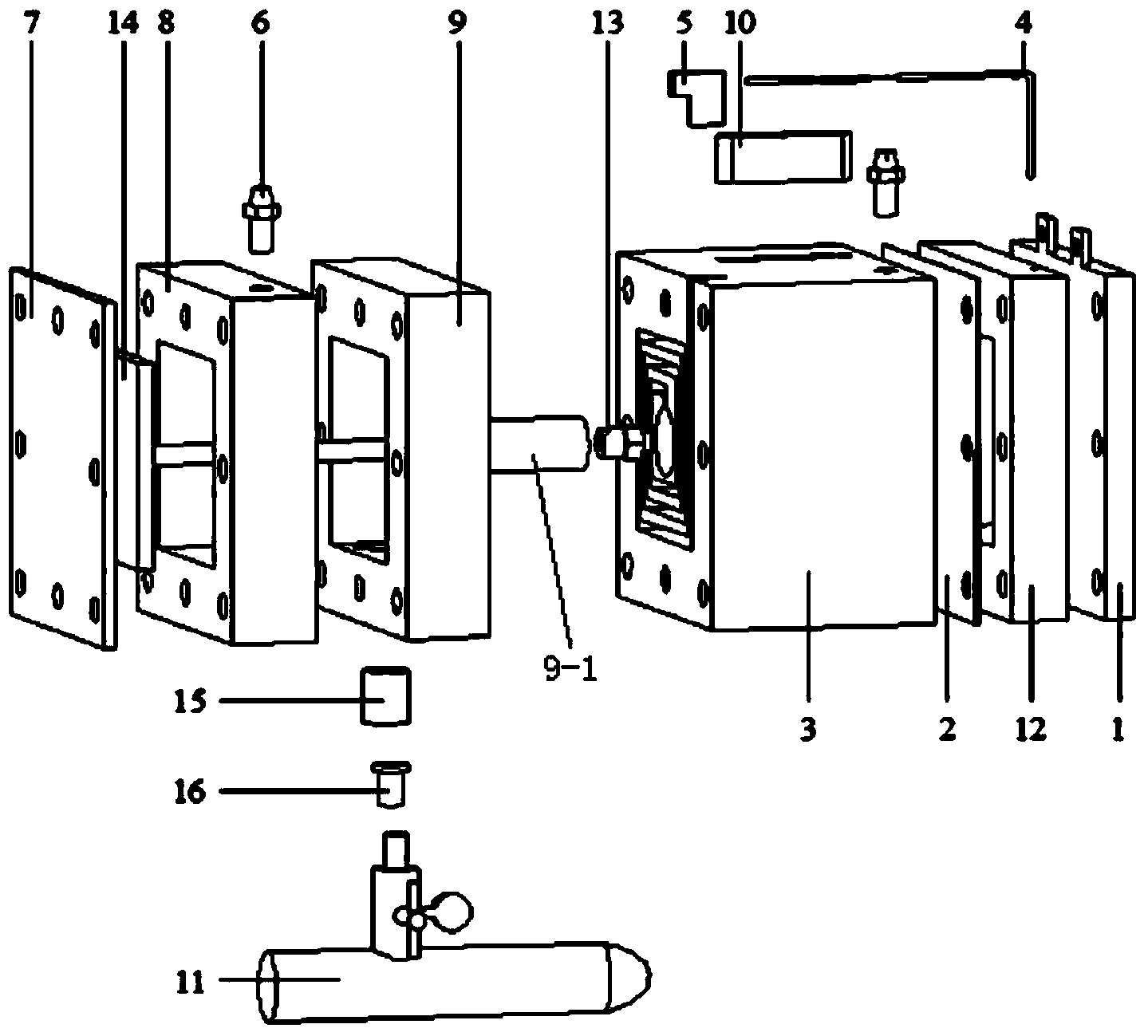

[0046] As shown in Figure 1-9. The catalytic combustion heat supply steam supply passive direct methanol fuel cell of the present invention comprises a battery reaction unit 1 and a porous sintered plate 20 therein, and the battery reaction unit 1 is sequentially connected with a steam supply unit 12, a pervaporation membrane 2, a catalytic combustion supply Heat unit 3, oxygen buffer unit 9, catalytic combustion raw material unit 8, sealed bottom cover 7;

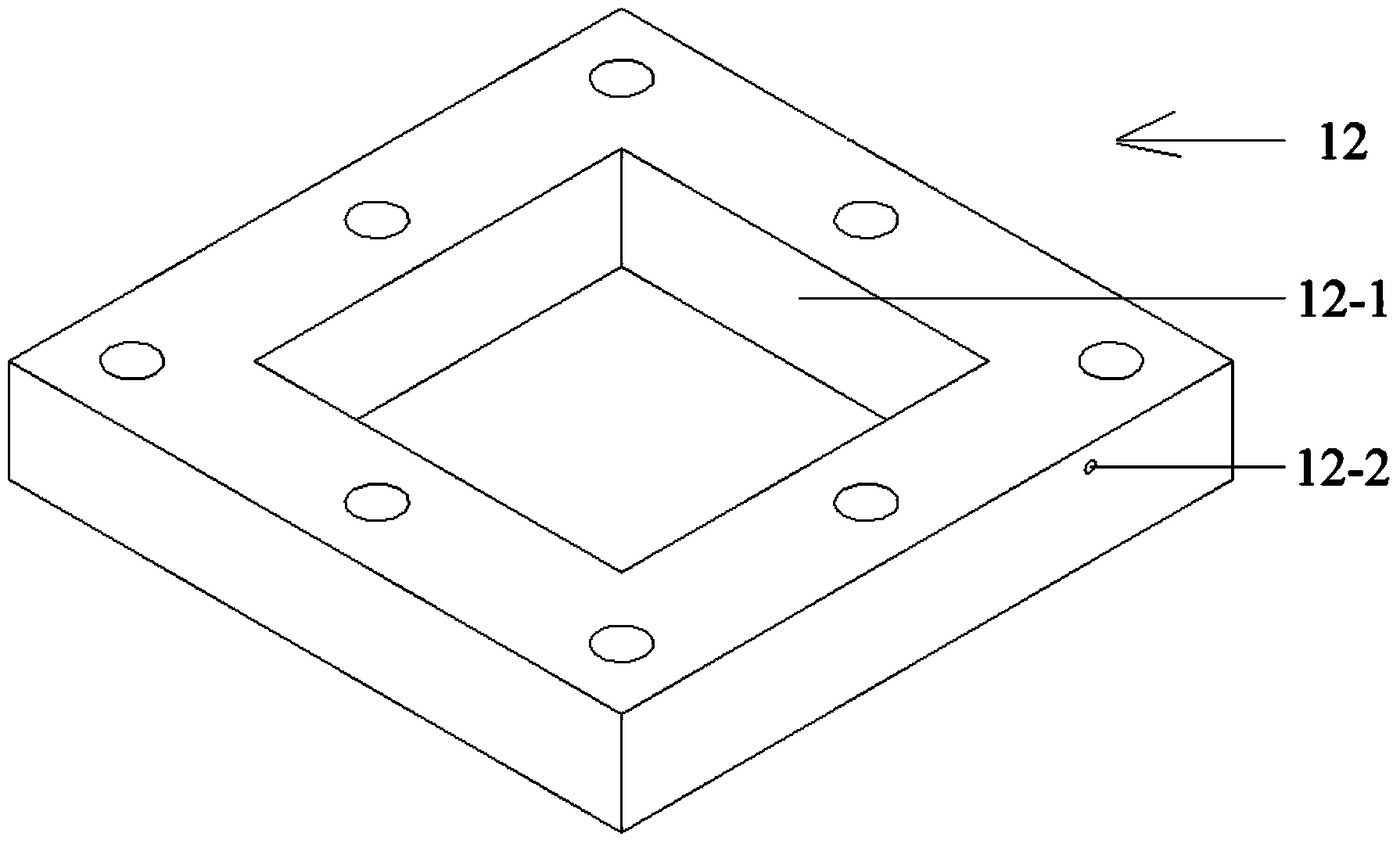

[0047] Such as image 3 As shown in , the steam supply unit 12 has an evaporation chamber 12 - 1 ; the steam chamber 12 is a buffer component between the battery reaction unit 1 and the pervaporation membrane 2 . Evaporation chamber 12-1 is made of transparent materials with good machinability, such as plexiglass, and the surface is polished to realize visual control of battery supply. Evaporation chamber 12-1 can be a regular square channel , the size is the same as the installation size of the porous sintered plate 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com