Directional backlight generation method and system

A directional and backlight technology, applied in the direction of optics, optical components, instruments, etc., can solve the problems of moiré fringes and backlight direction disorder, and cannot guarantee the alignment of a single cylindrical prism pixel 020, so as to reduce moiré fringes and improve directionality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

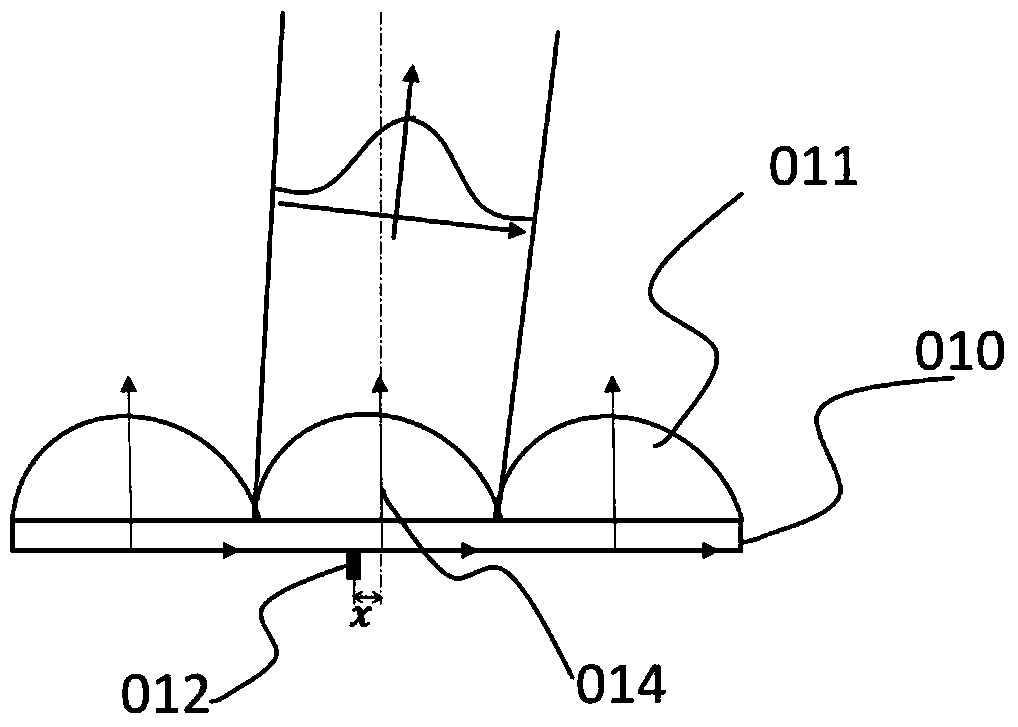

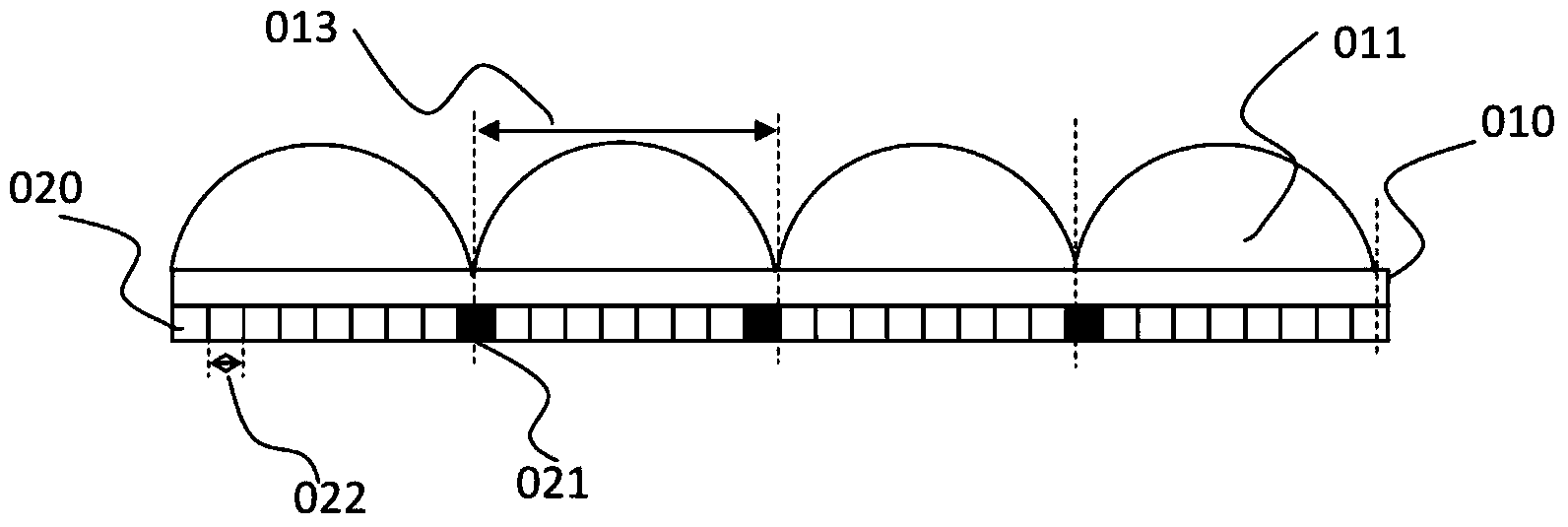

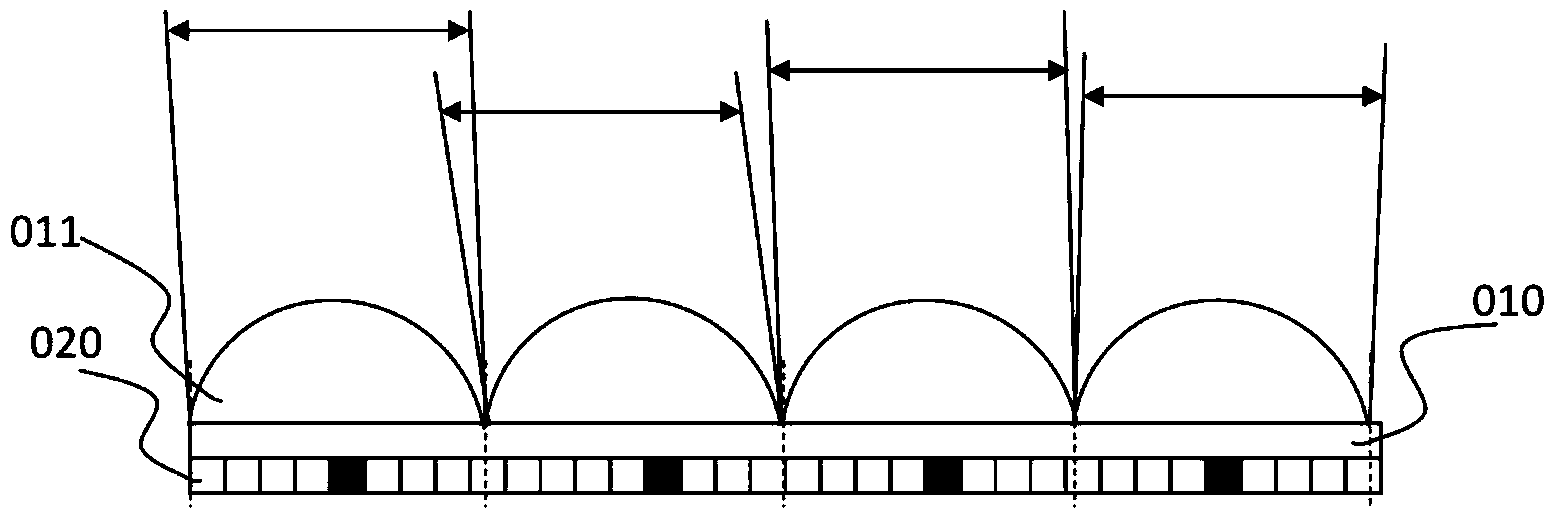

[0034] According to one aspect of the present invention, a method for generating directional backlight is proposed, which establishes an independent coordinate system 040 for each cylindrical prism 011 in the microcylindrical lens array, and generates a brightness line based on each independent coordinate system. The control curve 041, and the amplitude and phase of the curve can be controlled separately, the brightness control curve is discretely integrated with the corresponding pixel 020 below the cylindrical prism as the discrete interval, and the integration result of each discrete interval is used as the brightness of the corresponding pixel value. Changing the phase of the brightness control curve can change the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com