Actuation device with rotation-proof retaining nut

A technology of operating device and nut, applied in the direction of valve operation/release device, nut, valve device, etc., can solve problems such as current temperature fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

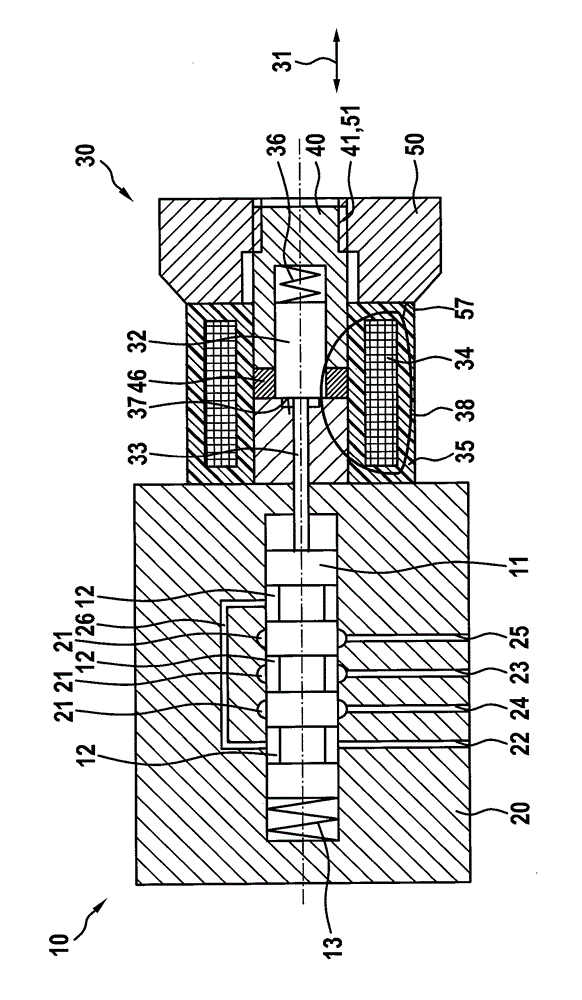

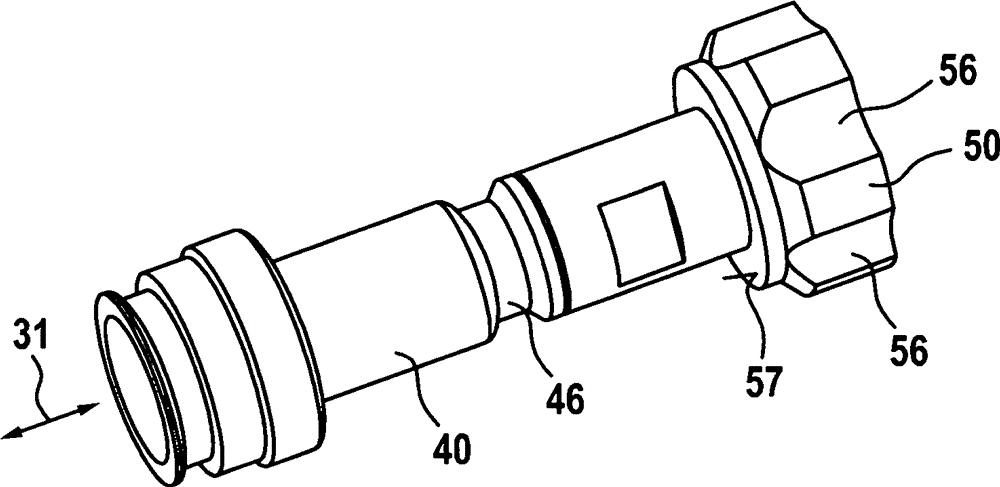

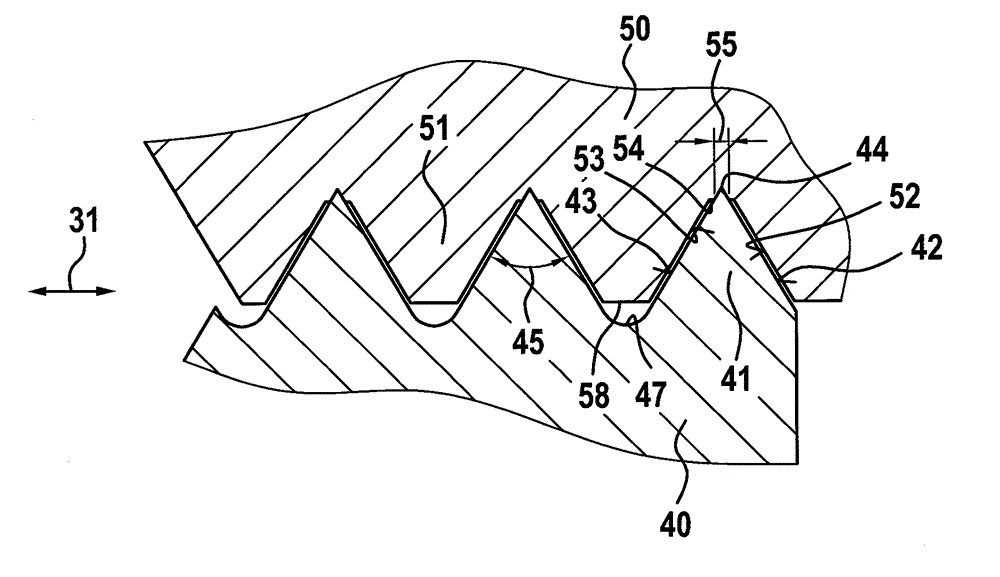

[0016] figure 1 A roughly schematic cross-section of a valve 10 with an actuating device 30 according to the invention is shown. The hydraulic valve 10 is shown by way of example as a slide valve, wherein the control body 11 is a control slide valve. However, the invention can also be used in seat valves. The valve 10 comprises a housing 20 , which is made, for example, of gray cast iron. The control body 11 is accommodated linearly displaceably with respect to the longitudinal direction 31 in a housing 20 which preferably consists of steel. The control body 11 is preferably designed with high precision in the form of a cylinder, wherein the control body is provided, for example, with three annularly encircling links 12 . In the housing 20 there is provided a cylindrical bore, preferably adapted with very little play to the control body 11 , which bore is provided with, for example, three annular housing grooves 21 . The link and the housing grooves 12 , 21 each define a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com