System and method for cooling high-temperature steam turbine rotor by gland seal

A steam turbine rotor and steam turbine technology, applied to mechanical equipment, engine components, machines/engines, etc., can solve problems such as hidden dangers in safe operation, reduced service life of bearings, and increased emulsification speed of lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

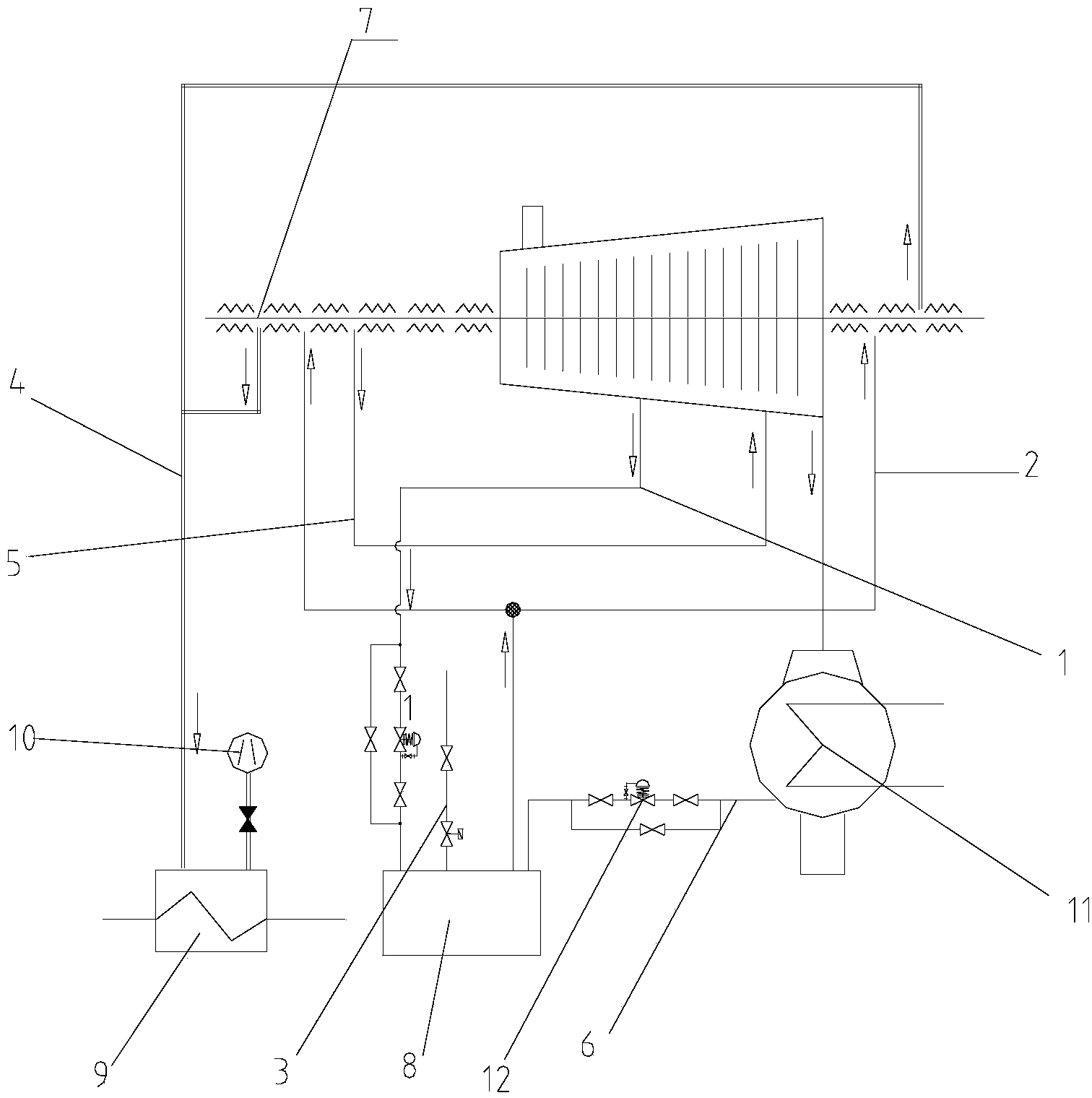

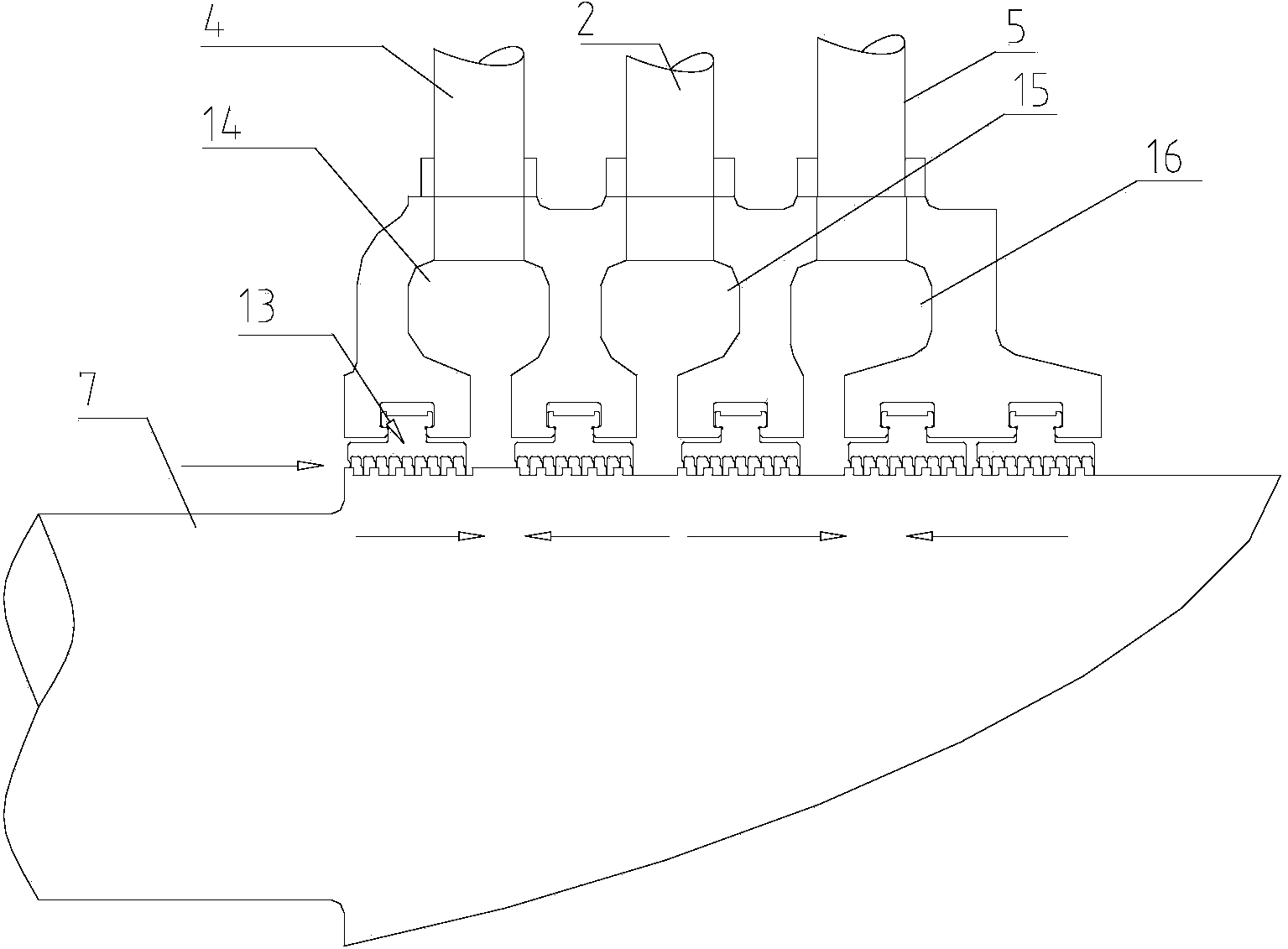

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] A system for cooling the rotor of a high-temperature steam turbine using a steam seal, including a steam seal system composed of a steam turbine seal 13, a pressure equalization box 8, a shut-off valve, a regulating valve, a self-operated pressure regulating valve 12 and a plurality of pipelines, of which No. 1 pipe The pipeline is connected to the pressure equalization box 8 from any position in the steam turbine body where the pressure is from 0.588MPa to 1.2MPa. An adjustment device is arranged on the No. 1 pipeline to keep the pressure range in the pressure equalization box 8 at 0.13-0.135MPa; The pressure equalization box 8 is connected to the second-end chamber 15 of the steam seal before and after the steam turbine, as the steam supply pipeline of the steam turbine seal; the No. 3 pipeline is the desuperheating water pipeline, which leads into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com