Mobile precast box girder curing machine

A mobile, box girder technology, applied in the direction of manufacturing tools, ceramic molding machines, injection devices, etc., to ensure the quality of the project, speed up the construction progress, and reduce the input of manpower and financial resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

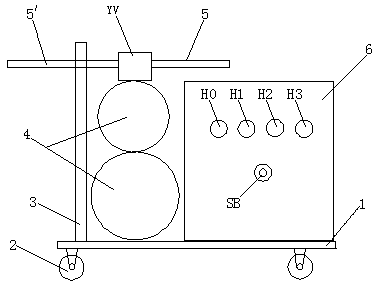

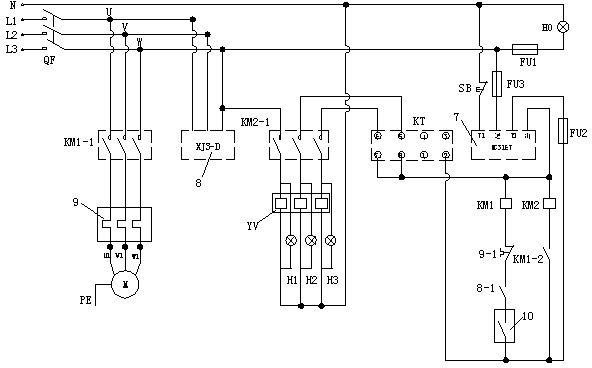

[0020] In the present invention figure 1 In the shown embodiment, a maintenance vehicle is composed of a rectangular frame 1, a universal 2 and a support frame 3; an electric control box 6 and a booster pump 4 are arranged on the maintenance vehicle, and a solenoid valve YV is arranged on the booster pump 4; The support frame 3 is welded on the rectangular frame 1 of the maintenance vehicle, and the outlet pipe 5' is installed and fixed on the upper end of the support frame 3; the water inlet pipe 5 is connected to the water inlet of the solenoid valve YV, and the water outlet of the solenoid valve YV is connected to one end of the water outlet pipe 5' Connect; the other end of outlet pipe 5' is connected with plastic hose. The control panel is hingedly installed on the electric control box 6, and the control panel is provided with an emergency stop button SB, a power indicator light H0, a first indicator light H1, a second indicator light H2, and a third indicator light H3; i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com