Static pressure dresser of super-grinding bearing outer ring raceway grinding wheel and dressing method

A bearing outer ring and dresser technology, which is used in grinding machine parts, grinding/polishing equipment, abrasive surface adjustment devices, etc. Dressing method and other issues, to achieve the effect of improving grinding wheel dressing efficiency, stable operation and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

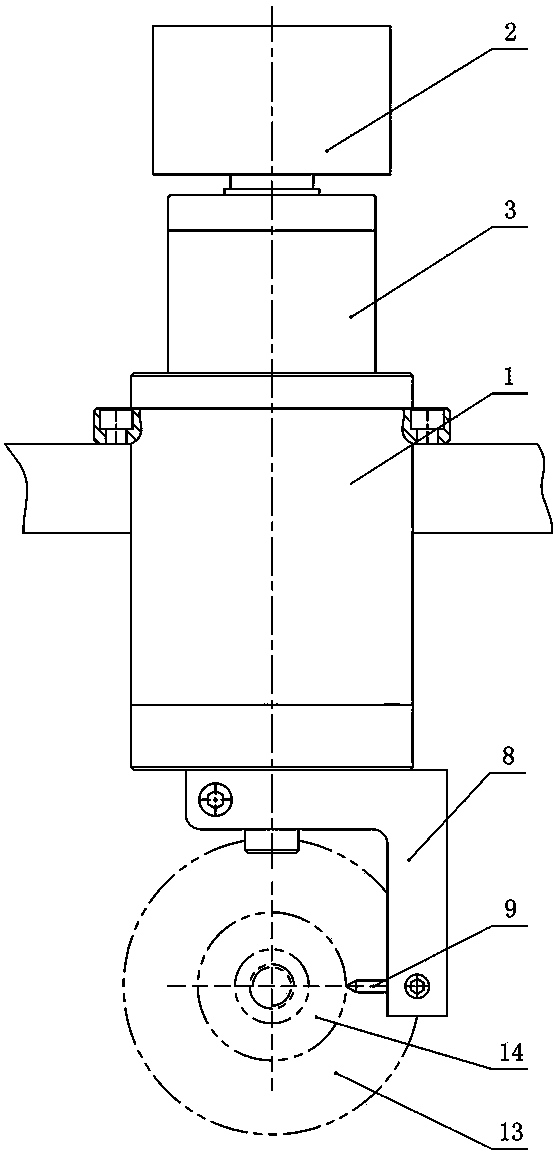

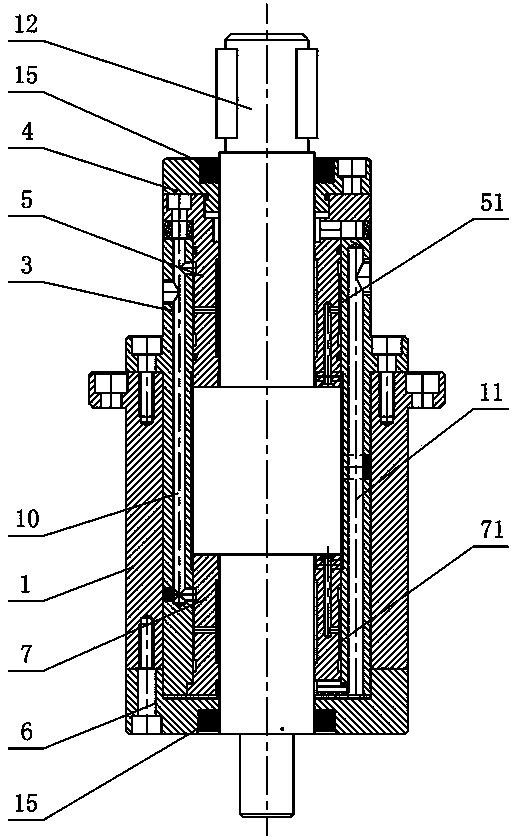

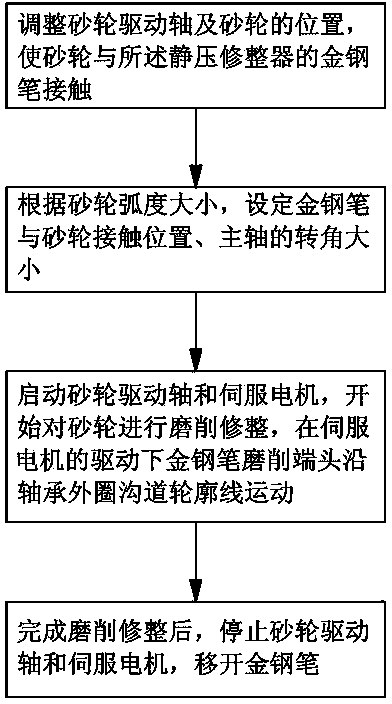

[0027] Figure 1 to Figure 2 It shows an embodiment of a static pressure dresser of the present invention for grinding the grinding wheel of the groove of the outer ring of a superfinishing ball bearing. The static pressure dresser includes a base cover 1, a servo motor 2, a sleeve 3, and an upper end cover 4 , Upper hydrostatic bearing 5, lower end cover 6, lower hydrostatic bearing 7, pen chuck 8, gold pen 9 and main shaft 12, sleeve 3 is set in base cover 1, main shaft 12 is set in sleeve 3, the upper end cover 4 and the lower end cover 6 are respectively arranged at the upper and lower ends of the sleeve 3, the upper hydrostatic bearing 5 and the lower hydrostatic bearing 7 are supported between the main shaft 12 and the sleeve 3, and the upper hydrostatic bearing 5 is located at the upper part of the main shaft 12, the lower hydrostatic bearing 7 is located at the lower part of the main shaft 12, the pen chuck 8 is installed at the lower end of the main shaft 12, the gold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com