Application method of kraft paper instead of spot welding flash in metal explosive composite board

A technology of explosive composite board and kraft paper, which is applied in the direction of metal processing, metal processing equipment, welding equipment, etc., can solve the problems of affecting the quality of explosive welding, complicated operation, and increasing weld seams, so as to save rare and precious metal composite board materials and prevent environmental pollution. Effects of pollution and wood cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 , Explosive welding production (316L+Q345R) 3 / 16×1800×4500mm metal composite board:

[0023] 316L stainless steel plate for compound board 3×1800×4500mm,

[0024] Q345R carbon steel plate for base plate 16×1800×4500mm;

[0025] Since the width of the most common 316L stainless steel plate on the market is 1800mm, it is necessary to tailor the 316L plate for tailor welding and increase the explosion flash, which is very wasteful. Therefore, the production process layout is based on the whole plate without tailor welding, that is, it needs to use 200g / ㎡ kraft paper instead of spot welding flash to increase the width of the drug distribution, the operation steps are as follows:

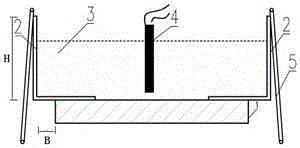

[0026] ①Crafting kraft paper strips: Because the height H of the drug frame designed by this explosive welding process is 50mm, the width of the drug distribution is increased B for 30 mm, 200g / ㎡The maximum length of kraft paper is 1100mm, so the kraft paper strip is cut so that the...

Embodiment 2

[0030] Example 2 , Explosive welding production (TA2+Q235B) 2 / 14×1500×4200mm metal composite board:

[0031] TA2 pure titanium plate for compound plate 2×1500×4200mm;

[0032] Q235B carbon steel plate for base plate 14×1500×4200mm;

[0033] The maximum plate width of the TA2 pure titanium plate available in the market is 1500mm. If the double plate needs to leave an explosion flash margin, it needs to cut the whole plate for typesetting and welding, which will cause a great waste of precious metal TA2 plate, so it is necessary to Use 200g / ㎡ kraft paper instead of spot welding flash to increase the cloth width, the operation steps are as follows:

[0034] ①Crafting kraft paper strips: Because the height H of the drug frame designed by this explosive welding process is 45mm, the width of the drug distribution is increased B for 25 mm, the maximum length of 200g / ㎡ kraft paper is 1100mm, the length of the cut kraft paper strip = 1100mm, so that the width of the kraft paper str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com