Preparation method for monodisperse bismuth nano-particles with controllable particle sizes

A monodisperse, bismuth nanotechnology, applied in nanotechnology and other directions, to achieve the effects of simple operation, controllable reaction conditions and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

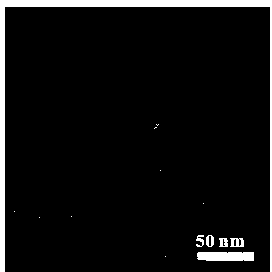

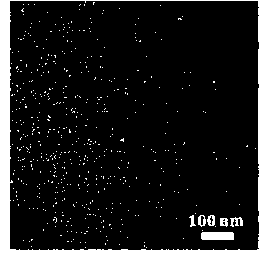

Image

Examples

Embodiment 1

[0019] 1. Preparation of tetrahydrofuran solution of bis(trimethylsilyl)aminobismuth:

[0020] At 0°C (such as in an ice-water bath), 2.15 g of lithium bis(trimethylsilyl)amide (Li[N(SiMe 3 ) 2 ]) was dissolved in 20 mL of diethyl ether solution to form a diethyl ether solution of lithium bis(trimethylsilyl)amide.

[0021] Dissolve 1.35 g of bismuth trichloride in a mixed solution of 20 mL of diethyl ether and 5 mL of tetrahydrofuran, and slowly add it dropwise to the diethyl ether solution of lithium bis(trimethylsilyl)amide, and magnetically stir for reaction 1 Hour.

[0022] After the reaction was completed, the reaction solution was filtered, and the yellow-green filtrate was rotary evaporated. Then, 10 mL of pentane was added to dissolve, and after filtration, the rotary evaporation was performed again to obtain a yellow powder, bis(trimethylsilyl)aminobismuth, which was dispersed into tetrahydrofuran to form a tetrahydrofuran solution of bis(trimethylsilyl)aminobismut...

Embodiment 2

[0030] 1. Preparation of tetrahydrofuran solution of bis(trimethylsilyl)aminobismuth:

[0031] At 0°C (such as in an ice-water bath), 2.15 g of lithium bis(trimethylsilyl)amide (Li[N(SiMe 3 ) 2 ]) was dissolved in 20 mL of diethyl ether solution to form a diethyl ether solution of lithium bis(trimethylsilyl)amide.

[0032] Dissolve 1.35 g of bismuth trichloride in a mixed solution of 20 mL of diethyl ether and 5 mL of tetrahydrofuran, and slowly add it dropwise to the diethyl ether solution of lithium bis(trimethylsilyl)amide, and magnetically stir for reaction 1 Hour.

[0033] After the reaction was completed, the reaction solution was filtered, and the yellow-green filtrate was rotary evaporated. Then, 10 mL of pentane was added to dissolve, and after filtration, the rotary evaporation was performed again to obtain a yellow powder, bis(trimethylsilyl)aminobismuth, which was dispersed into tetrahydrofuran to form a tetrahydrofuran solution of bis(trimethylsilyl)aminobism...

Embodiment 3

[0041] 1. Preparation of tetrahydrofuran solution of bis(trimethylsilyl)aminobismuth:

[0042] At 0°C (such as in an ice-water bath), 2.15 g of lithium bis(trimethylsilyl)amide (Li[N(SiMe 3 ) 2 ]) was dissolved in 20 mL of diethyl ether solution to form a diethyl ether solution of lithium bis(trimethylsilyl)amide.

[0043] Dissolve 1.35 g of bismuth trichloride in a mixed solution of 20 mL of diethyl ether and 5 mL of tetrahydrofuran, and slowly add it dropwise to the diethyl ether solution of lithium bis(trimethylsilyl)amide, and magnetically stir for reaction 1 Hour.

[0044] After the reaction was completed, the reaction solution was filtered, and the yellow-green filtrate was rotary evaporated. Then, 10 mL of pentane was added to dissolve, and after filtration, the rotary evaporation was performed again to obtain a yellow powder, bis(trimethylsilyl)aminobismuth, which was dispersed into tetrahydrofuran to form a tetrahydrofuran solution of bis(trimethylsilyl)aminobismut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com