Improved-type methyl chloroformate tower reactor

A methyl chloroformate, tower reactor technology, applied in the preparation of phosgene or haloformate, chemical instruments and methods, chemical/physics/physicochemical processes, etc., can solve the constraints on the quality and production capacity of methyl chloroformate. And safety and environmental protection, PP material is not easy to seal, the tower flange is large, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

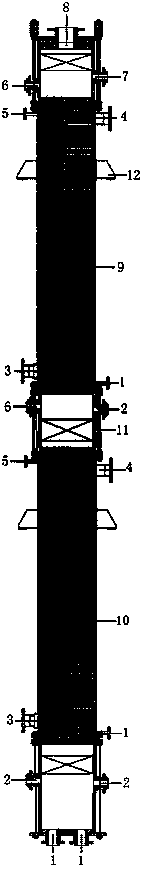

[0014] Such as figure 1 As shown, the improved methyl chloroformate tower reactor includes a tower body and a material outlet 7, a material inlet 2, a sewage outlet 1, a frozen water inlet 3, a frozen water outlet 4, and an air inlet 12 arranged on the tower body. and exhaust gas outlet 8, the tower body is composed of an upper tower body 9 and a lower tower body 10, and a soft joint 11 is installed between the upper tower body 9 and the lower tower body 10; the sealing surface of the tower joint adopts a graphite surface, and the surface Sealing lines are engraved on it; the upper tower body 9 and the lower tower body 10 are left with a vent port 5 and a thermometer port 6; the air inlet 12 in the tower is provided with a graphite Raschig ring as a redistributor, and the upper tower body Body 9 tops are also equipped with demisters.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com