A Tunable Slab Laser

A strip laser and optical path technology, which is applied in the field of lasers to achieve the effects of simple structure, reasonable design and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

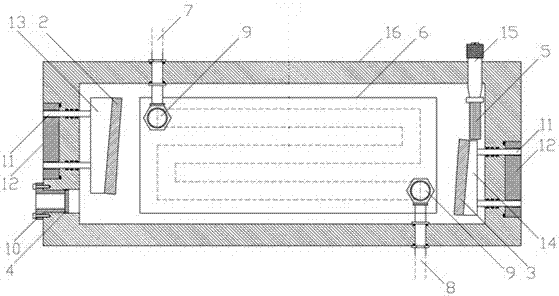

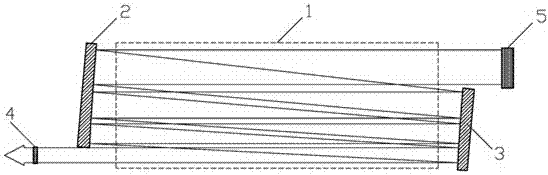

[0031] A tunable slab laser, including a vacuum cavity, the vacuum cavity is an all-metal structure. In this embodiment, the material is aluminum, which has good heat dissipation, light weight, and heat treatment during processing to reduce deformation. The radio frequency power supply is connected to the upper and lower walls of the inner wall of the vacuum chamber through a transmission line to form a waveguide cavity. An optical path folding system is arranged horizontally in the vacuum chamber, and the optical path folding system includes a reflective blazed grating, a total reflection concave mirror, a total reflection convex mirror and a partial reflection output mirror. The reflective blazed grating and the total reflection convex mirror are installed on the inner surface of the vacuum chamber On the side wall of the total reflection concave mirror and the partial reflection output mirror are installed on the inner surface of the vacuum chamber on the side wall opposite ...

Embodiment 2

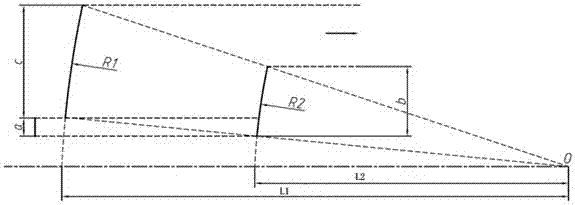

[0035] On the basis of Embodiment 1, the focal point O of the total reflection concave mirror and the total reflection convex mirror coincide (confocal), and the distance L2 between the confocal point O and the total reflection convex mirror is half of the radius of curvature R2 of the total reflection convex mirror , the distance L1 between the confocal point O and the total reflection concave mirror is half of the curvature radius R1 of the total reflection convex mirror, the specific design is as follows figure 2 shown. Such a design can make each folded optical path of the oscillating beam as close as possible to achieve the purpose of fully utilizing the gain working medium and improving laser efficiency. The outgoing light after the oscillating light is frequency-selected through the reflective blazed grating is parallel light, and the incident light that enters the partial reflection output mirror after being reflected by the total reflection convex mirror for the last...

Embodiment 3

[0037] On the basis of Embodiment 1 or Embodiment 2, two electrodes, upper and lower, are vertically arranged in the vacuum chamber. The electrodes can be made of aluminum or copper. In this embodiment, the electrode material is copper, and the upper electrode is close to the inside of the vacuum chamber. The top surface and the lower electrode are close to the bottom surface of the vacuum cavity. The distance between the upper and lower electrodes is 1~3mm. The two electrodes are connected to the RF power supply through the transmission line and form a gain interval between the electrodes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com