A method for measuring the depth and shape of the subsurface damaged layer of optical materials

A technology of subsurface damage and optical materials, applied in the direction of electric/magnetic depth measurement, electric/magnetic thickness measurement, measuring device, etc., can solve the problems of complex data processing, complicated sample preparation process, and unintuitive test results, etc. High precision, strong applicability, suitable for large-scale promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] The sub-surface damage layer of the optical element includes a sub-surface crack layer and an internal stress deformation layer, and is covered by a polishing relamination layer on the non-damage substrate. Because it is below the surface, it is not easy to observe directly.

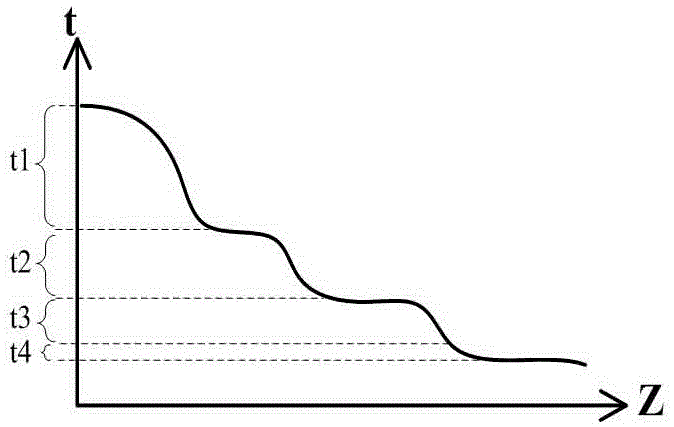

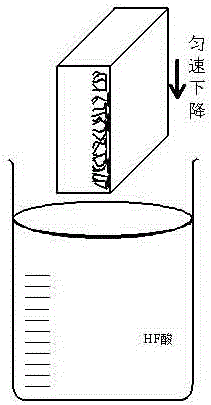

[0030] The invention provides a method for measuring the depth and shape of the subsurface damage layer of an optical material. The method controls the sample to move continuously and slowly along the vertical direction in the HF acid solution, and uses HF acid to continuously corrode the sample. , so that the corrosion degree of different positions and layers of the sample changes continuously, and the corroded section surface is obtained. The corroded cut surface is scanned with a probe-type profiler, and the depth of the subsurface damage layer of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com