Sampling apparatus and sampling method

A technology of sampling device and monitoring device, which is applied in the direction of sampling device, etc., can solve the problem that the sampling device is not easy to clean, and achieve the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] As mentioned in the background, prior art sampling devices are difficult to clean.

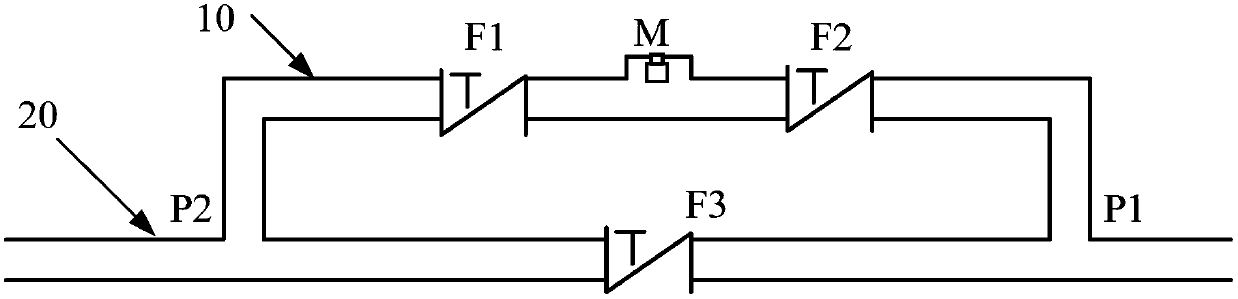

[0037] figure 1 It is a sampling device, and the sampling device includes: a drainage tube 10; a first valve F1 and a second valve F2, located between the two ports of the drainage tube 10; a sampling plug M, located between the first valve F2 and the second valve F3 In the drainage tube 10 between.

[0038] The test tube 20 is part of the device for producing chemical samples, and the test tube 20 has a P1 port and a P2 port; a third valve F3 is arranged in the test tube 20 . The two ports of the drainage tube 10 communicate with the two ports of the test tube 20 respectively. The third valve F3 is disposed between two ports of the test tube 20 . The test tube 20 and the sampling device are integrally formed. The chemical sample is titanium tetrachloride.

[0039] When titanium tetrachloride is produced, titanium tetrachloride enters through port P1 and flows out from port P2 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com