Functional chinlon 6 colored fiber and manufacturing method thereof

A technology for colored fibers and manufacturing methods, applied in the directions of melt spinning, single-component polyamide rayon, melting of filament raw materials, etc., can solve the problem of lack of UV resistance, poor color fastness, and lack of antibacterial and other problems, to achieve good dye-free antibacterial and anti-ultraviolet effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

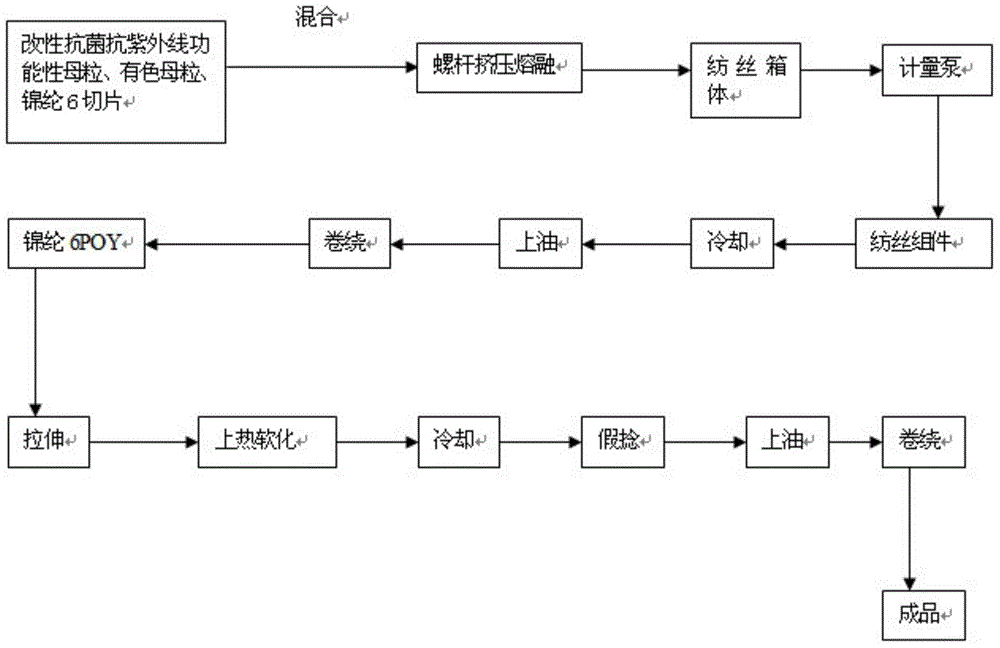

Method used

Image

Examples

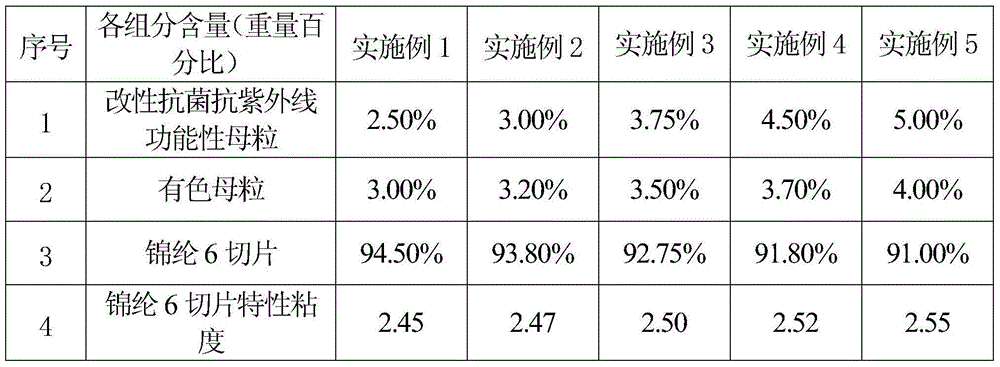

Embodiment 1

[0035] Dry the modified antibacterial and anti-ultraviolet functional masterbatch and black masterbatch at a temperature of 85°C for 8 hours. The moisture content of antibacterial and anti-ultraviolet functional masterbatch and black masterbatch is controlled below 600PPM. Evenly mix the dried modified antibacterial and anti-ultraviolet functional masterbatch, the black masterbatch and the dried nylon 6 slices. The component composition of the above mixture is shown in Table 1 below. Among them, the modified antibacterial and anti-ultraviolet functional masterbatch contains sodium silver zirconium phosphate, and its composition is shown in Table 2 below. Black masterbatch includes 40% pigment black components, 0.4% dispersant and 59.6% nylon 6 chips.

[0036] The mixture of dry modified antibacterial and anti-ultraviolet functional masterbatch, black masterbatch and nylon 6 chips was added to a screw extruder for melt extrusion. The temperature and melt pressure of the heati...

Embodiment 2

[0041] Dry the modified antibacterial and anti-ultraviolet functional masterbatch and gray masterbatch at a temperature of 80°C for 8 hours. The moisture content of antibacterial and anti-ultraviolet functional masterbatch and gray masterbatch is controlled below 600PPM. Evenly mix the dried modified antibacterial and anti-ultraviolet functional masterbatch, the gray masterbatch and the dried nylon 6 slices. The component composition of the above mixture is shown in Table 1 below. Among them, the modified antibacterial and anti-ultraviolet functional masterbatch contains sodium silver zirconium phosphate, and its composition is shown in Table 2 below. Gray masterbatch includes 45% pigment ash component, 0.5% dispersant and 54.5% nylon 6 chips.

[0042] Add the dry modified antibacterial and anti-ultraviolet functional masterbatch, the mixture of gray masterbatch and nylon 6 chips into the spinning screw extruder for melt extrusion. The temperature and melt pressure of the heat...

Embodiment 3

[0047] Dry the modified antibacterial and anti-ultraviolet functional masterbatch and brown masterbatch at a temperature of 85°C for 7 hours. The moisture content of antibacterial and anti-ultraviolet functional masterbatches and brown masterbatches is controlled below 600PPM. Evenly mix the dried modified antibacterial and anti-ultraviolet functional masterbatch, brown masterbatch and dried nylon 6 chips. The component composition of the above mixture is shown in Table 1 below. Among them, the modified antibacterial and anti-ultraviolet functional masterbatch contains sodium silver zirconium phosphate, and its composition is shown in Table 2 below. Brown masterbatch includes 50% brown pigment components, 0.6% dispersant and 49.4% nylon 6 chips.

[0048] Add the dry modified antibacterial and anti-ultraviolet functional masterbatch, the mixture of brown masterbatch and nylon 6 chips into the spinning screw extruder for melt extrusion. The temperature and melt pressure of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com