A copper ion concentration automatic balance control device and control method thereof

An automatic balance and control device technology, applied in the direction of cells, electrolysis process, electrolysis components, etc., can solve the problems of affecting product quality, no way to refine sulfuric acid, increase power consumption, etc., to reduce subsequent processing costs and reduce the generation of copper sludge , Improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

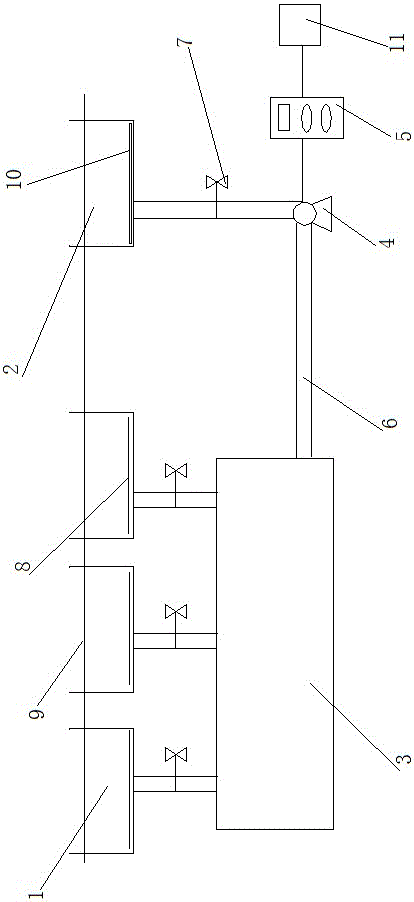

[0026] Embodiment 1: as figure 1 As shown, a copper ion concentration automatic balance control device includes at least one electroplating tank 1, a specific tank 2, and a buffer tank 3. The connection sequence is that the specific tank is connected to the electroplating tank through a pipeline 6, and the electroplating tank is connected to the buffer tank through a pipeline. , the buffer tank is connected to the specific tank through pipelines, an overflow device is provided on the electroplating tank, and the excess electrolyte flows to the buffer tank through the pipeline, and an automatic pump 4 is also arranged on the pipeline between the specific tank and the buffer tank. Cu 2+ The on-line monitor 5 is connected on the buffer tank, and the PLC controller 11 is connected on the Cu 2+ On the online monitor, a valve 7 is set on the pipeline from the electroplating tank to the buffer tank, and a valve is also set on the pipeline between the automatic pump and the specific ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com