A kind of preparation method of surfactant for detergent

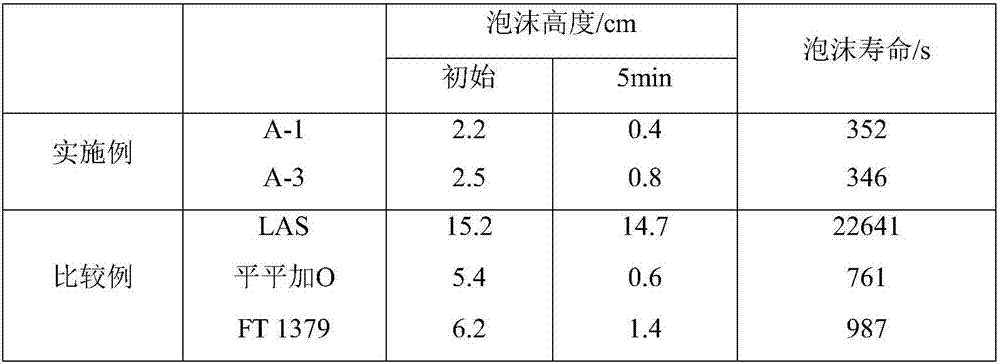

A surfactant and detergent technology, applied in the field of surfactant preparation, can solve the problems of poor washing effect of detergent, large amount of dust generated by dust-free clothing, and damage to clothing fibers, etc., and achieve low decontamination ability and easy foaming Effects of rinsing, large amount of dust generation, and high cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

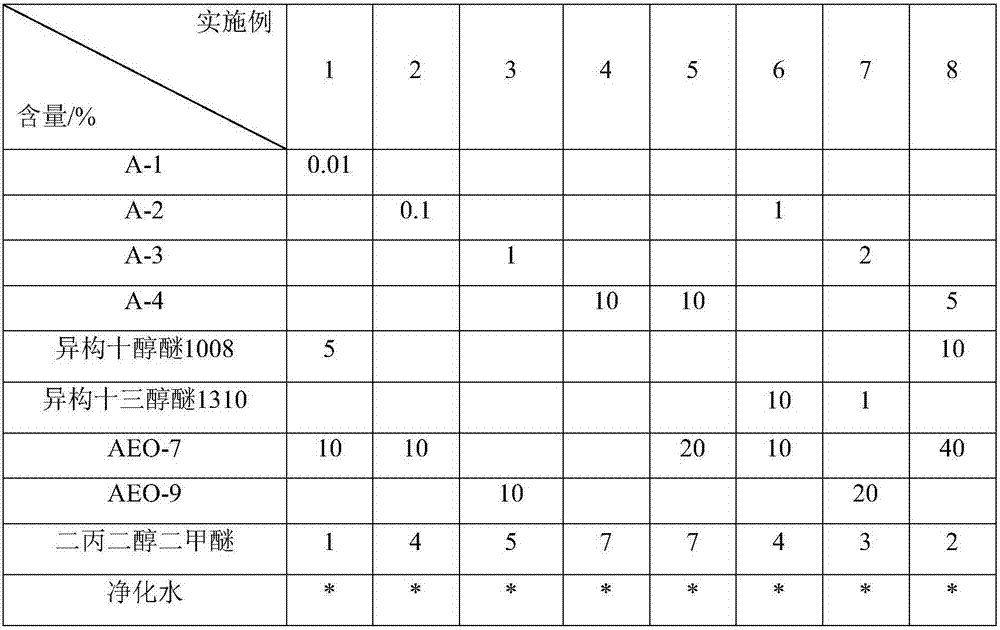

preparation Embodiment 1

[0044] Take 24.2g (0.1mol) of dodecyl glycidyl ether, 18.6g (0.1mol) of dodecyl alcohol and add them to the reactor at room temperature in turn, then add 0.01g of NaOH catalyst, replace the air with nitrogen, and heat at 70°C Under the reaction 3h. The temperature was raised to 85°C, vacuumed at a constant temperature for 20 minutes, then the temperature was raised to 130°C, 22g (0.5mol) of ethylene oxide was continuously introduced, and the pressure of the reactor was controlled to 0.15MPa. starting pressure. Lower the reaction temperature to 50°C, add 18.5g (0.2mol) of epichlorohydrin dropwise within 30 minutes to carry out the ring-opening reaction, after stirring at constant temperature for 3 hours, remove excess epichlorohydrin by distillation under reduced pressure; raise the temperature to 200°C, add 12.1 g of polyethylene polyamine (diethylenetriamine and triethylenetetramine mixed at a mass ratio of 1:1) were reacted for 4 hours to obtain the detergent surfactant (A-...

preparation Embodiment 2

[0046]Take 32.6g (0.1mol) of octadecyl glycidyl ether, 27g (0.1mol) of stearyl alcohol and add them to the reactor at room temperature, then add 0.01g of NaOH catalyst, replace the air with nitrogen, and heat at 80°C Reaction 2h. Then the temperature rises to 90°C, vacuumizes at constant temperature for 20min, then raises the temperature to 180°C, continuously feeds 30.8g (0.7mol) ethylene oxide, controls the reactor pressure to 0.3MPa, completes feeding of ethylene oxide, and keeps warm to pressure down to the starting pressure. Lower the reaction temperature to 60°C, add 27.75g (0.3mol) of epichlorohydrin dropwise within 30min to carry out the ring-opening reaction, stir at constant temperature for 2h, distill off excess epichlorohydrin under reduced pressure; raise the temperature to 200°C, add 29.3g of polyethylene polyamine (triethylenetetramine and tetraethylenepentamine mixed at a mass ratio of 2:1) were reacted for 6h to obtain the detergent surfactant (A-2) of this e...

preparation Embodiment 3

[0048] Take 27g (0.1mol) tetradecyl glycidyl ether, 48.4g (0.2mol) hexadecyl alcohol and add them to the reactor at room temperature, then add 0.01g NaOH catalyst, replace the air with nitrogen, and heat to 80°C Under reaction 2h. Then the temperature rises to 90°C, vacuumizes at a constant temperature for 20 minutes, raises the temperature to 150°C, continuously feeds 26.4g (0.6mol) of ethylene oxide, and controls the reactor pressure to 0.6MPa. The pressure is reduced to the starting pressure. Lower the reaction temperature to 60°C, add 18.3g (0.2mol) of epichlorohydrin dropwise within 30min to carry out the ring-opening reaction, stir at constant temperature for 2 hours, and distill off excess epichlorohydrin under reduced pressure; raise the temperature to 200°C, add 54g of polyethylene polyamine (diethylenetriamine, triethylenetetramine and tetraethylenepentamine mixed in a mass ratio of 1:1:1) was reacted for 5h to obtain the detergent surfactant (A-3) of this example. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com