Method for improving bio-oil stability by adding compound additives

A compound additive and bio-oil technology, which is applied in the fields of fuel additives, petroleum industry, liquid carbon-containing fuels, etc., can solve the problems of poor storage stability of bio-oil and large variation of kinematic viscosity with storage time, and improve the stability of bio-oil. , Effective storage time is long, and the effect of reducing the kinematic viscosity value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

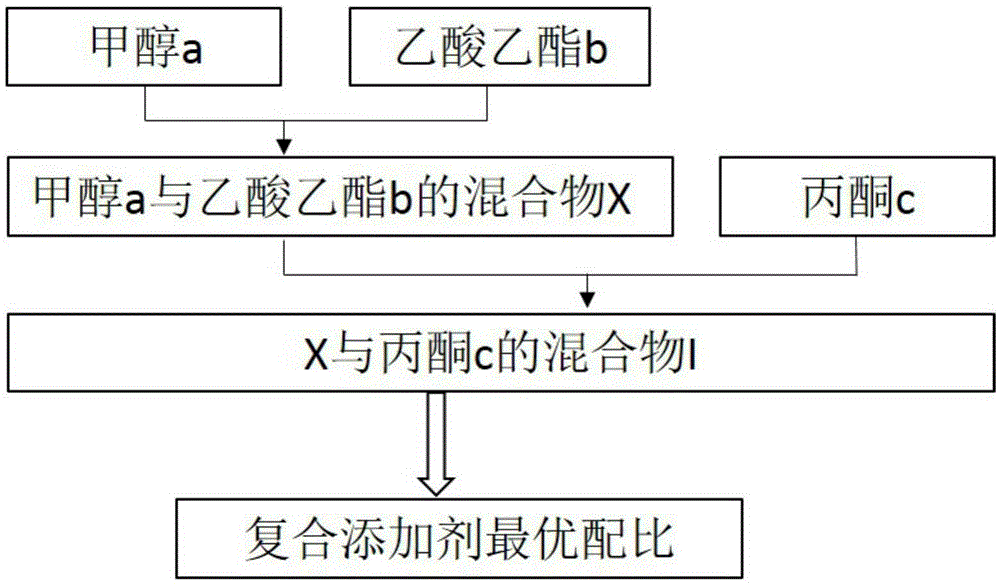

Method used

Image

Examples

Embodiment 1

[0039] This embodiment relates to a method for improving the stability of bio-oil by adding composite additives, said method comprising the steps of:

[0040] Using rice husk as raw material, the bio-oil was produced by using the bubbling fluidized bed biomass rapid pyrolysis device independently developed by the Biomass Energy Engineering Center of the School of Agriculture and Biology, Shanghai Jiaotong University. This device has been published by Liu Ronghou et al. (Liu, R.H., Shen, C.J., Wu, H.J., etc. Characterization of bio-oil from fast pyrolysis of rice huskina fluidised bed reactor [J]. Journal of the Energy Institute, 2011, 84(2): 73-79.).

[0041] The first step, preparation of biomass raw materials: use rice husks, pass through sieves with different meshes, take the sifted rice husks, and dry them at 105±0.5°C for 48±0.05h; the sieved rice husks, grain The diameter is 60 mesh;

[0042] The second step, the production of bio-oil: use the bubbling fluidized bed bio...

Embodiment 2

[0069] This embodiment relates to a method for improving the stability of bio-oil by adding composite additives, said method comprising the steps of:

[0070] Using rice husk as raw material, the bio-oil was produced by using the bubbling fluidized bed biomass rapid pyrolysis device independently developed by the Biomass Energy Engineering Center of the School of Agriculture and Biology, Shanghai Jiao Tong University. This device has been published by Liu Ronghou et al. (Liu, R.H., Shen, C.J., Wu, H.J., etc. Characterization of bio-oil from fast pyrolysis of rice huskina fluidised bed reactor [J]. Journal of the Energy Institute, 2011, 84(2): 73-79.).

[0071] The first step, preparation of biomass raw materials: use rice husks, pass through sieves with different meshes, take the sifted rice husks, and dry them at 105±0.5°C for 48±0.05h; the sieved rice husks, grain The diameter is 70 mesh;

[0072] The second step, the production of bio-oil: use the bubbling fluidized bed bi...

Embodiment 3

[0080] This embodiment relates to a method for improving the stability of bio-oil by adding composite additives, said method comprising the steps of:

[0081] Using rice husk as raw material, the bio-oil was produced by using the bubbling fluidized bed biomass rapid pyrolysis device independently developed by the Biomass Energy Engineering Center of the School of Agriculture and Biology, Shanghai Jiao Tong University. This device has been published by Liu Ronghou et al. (Liu, R.H., Shen, C.J., Wu, H.J., etc. Characterization of bio-oil from fast pyrolysis of rice huskina fluidised bed reactor [J]. Journal of the Energy Institute, 2011, 84(2): 73-79.).

[0082] The first step, preparation of biomass raw materials: use rice husks, pass through sieves with different meshes, take the sifted rice husks, and dry them at 105±0.5°C for 48±0.05h; the sieved rice husks, grain The diameter is 80 mesh;

[0083] The second step, the production of bio-oil: use the bubbling fluidized bed bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com