Facility secondary NO3<-> salinized soil improver, preparation method thereof and improving method

A soil conditioner and soil improvement technology, applied in the field of secondary NO3-salinated soil conditioners in facilities, can solve the problems that microbial cells cannot perform normal metabolic activities, cannot perform normal activities, and soil osmotic pressure, etc. The effect of salt leaching, improving soil structure and reducing soil salinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of soil conditioner A comprises the steps:

[0034] The first step is to mix stalk powder, rice bran and rapeseed cake evenly, add EM stock solution and brown sugar to the mixture, and then add water to make the water content about 35%;

[0035] The second step is airtight fermentation, the fermentation temperature is above 22°C, and the fermentation time is 10-26 days.

[0036] After the preparation is completed, it is best to adjust the C / N ratio of the improver, it is best to use straw powder to adjust the C / N ratio to 30-50, N+P 2 o 5 +K 2 O≧5%.

[0037] In this example, straw powder (C / N is 65-85:1), rice bran (C / N is 18-22:1), and rapeseed cake (C / N is 9-13:1) are all available on the market. purchased. Among them, this embodiment preferably prepares products with a C / N ratio between 30 and 50. The basis for the selection of C / N is as follows: microorganisms need to consume necessary nutrients and energy to maintain life activities and...

Embodiment 1~4

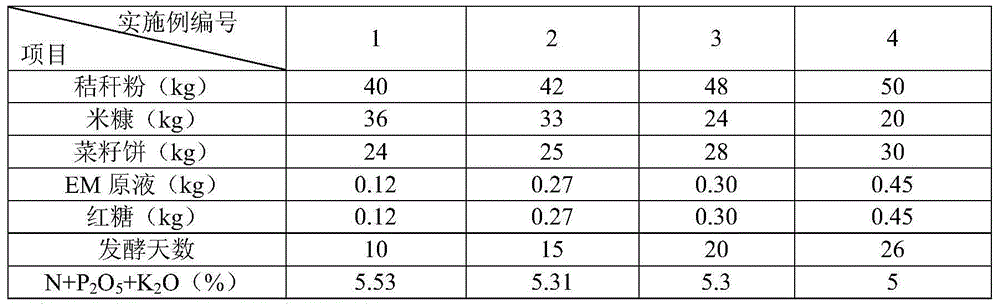

[0043] The preparation of embodiment 1~4 soil conditioner

[0044] The soil improver A of the present invention, after mixing raw materials in different proportions, adjusts the water content to about 35% (w / w), puts it into a plastic bucket with a cover for airtight fermentation, the fermentation temperature is above 22°C, and the fermentation time is 10-26 After 1 day, the fermentation is completed when the aroma is released, and the C / N ratio is adjusted to 30-50 with straw powder. The raw material components are as follows:

[0045]

[0046] Soil conditioner B is prepared according to the following steps:

[0047] The first step, the Ca(NO 3 ) 2 、KNO 3 , NaCl and KCl were mixed according to the mass ratio of 5:3:1:1, as an inorganic salt mixture, a 0.5wt% inorganic salt solution was prepared, and glucose was used as a carbon source, and 1-2mL EM stock solution was inoculated to 100mL inorganic salt The mixture was placed in a 250mL Erlenmeyer flask, 30°C, 170r / min ...

Embodiment 5

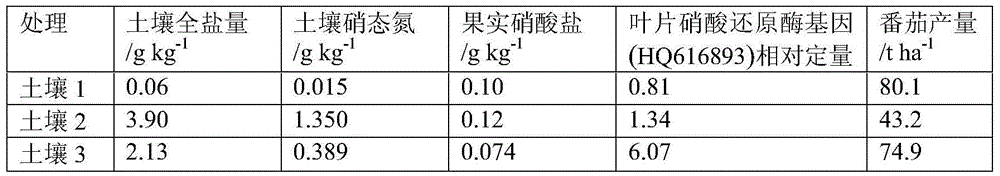

[0050] The soil improver obtained in Example 1 was selected for tomato planting on different types of soil.

[0051] Among them, soil 1 is the soil of normal facilities, and no secondary salinization of soil occurs.

[0052] Soil 2 is medium-slight facility secondary salinized soil, with total salt content of 2.10g / kg, soil nitrate nitrogen of 0.44g / kg, and pH6.1.

[0053] Soil 3 is to adopt the soil improver of embodiment 1 on the basis of soil 2 to carry out soil improvement. The specific method is: the plow layer soil (0~10cm) of the facility to be planted is piled up into a height of 35~40cm, according to 1‰ The mass ratio of the improved agent A was added, mixed well, and then co-cultivated at 35-50°C for 5-7 days. One day before crop planting, the soil surface was covered with 0-10cm, and tomato seedlings were transplanted. After 7 days, the crops The rhizosphere was sprayed with 500-fold diluted improver B (amount of 3000kg / ha); after that, the improver B was sprayed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com