Rare earth-doped optical fiber perform and preparation method thereof

An optical fiber preform and rare earth technology, which is applied to glass manufacturing equipment, manufacturing tools, etc., can solve the problems of low efficiency, large heat generation, and low longitudinal uniformity of optical fiber preforms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a method for preparing an optical fiber preform, comprising the following steps:

[0028] 1) depositing a loose core layer on the inner surface of the quartz deposition tube;

[0029] 2) Soak the quartz deposition tube with a loose core layer deposited on the inner surface obtained in step 1) in a solution containing rare earth elements, and after the head of the quartz deposition tube is soaked, the The solution is released according to the release rate obtained by formula a;

[0030] Release speed (mm / min) = L / (3h×L / 400mm-280h (mm / min) / V) / 60 Formula a;

[0031] In formula a, L is the length of the quartz deposition tube in the step 1), and the unit is mm;

[0032] V is the deposition velocity of depositing the loose core layer on the inner surface of the quartz deposition tube in the step 1), in mm / min;

[0033] 3) Drying, sintering and shrinkage of the quartz deposition tube soaked in step 2) in sequence to obtain a rare earth-doped optical ...

Embodiment 1

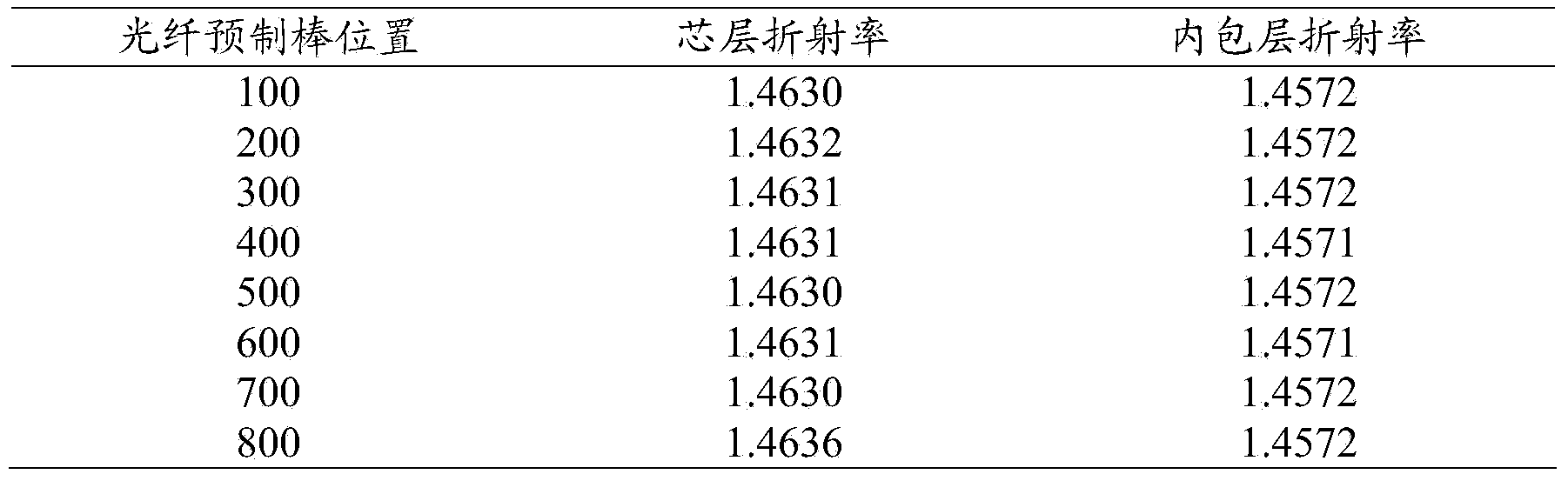

[0065] First, weld one end of the 1200mm quartz deposition tube to the handle tube, then install the tail tube on the chuck on the other side, and weld the other end of the deposition tube to the tail tube after straightening; lock the tailstock to avoid deposition Process movement, move the upper limit and lower limit respectively to the corresponding position;

[0066] Start the recipe program, the PLC controls the computer to synchronize with the equipment, and runs in the order of etching, inner cladding deposition, pre-shrinking, and loose core layer deposition, in which the inner cladding layer is deposited 9 layers, the components are Si-F-P three systems, and the raw materials are SiCl respectively. 4 , SF 6 and POCl 3 ;

[0067] The deposition speed of the loose core layer is 135mm / min. After the deposition of the loose core layer is completed, the formula program is closed. When the internal pressure drops to a negative value, the connection between the deposition ...

Embodiment 2

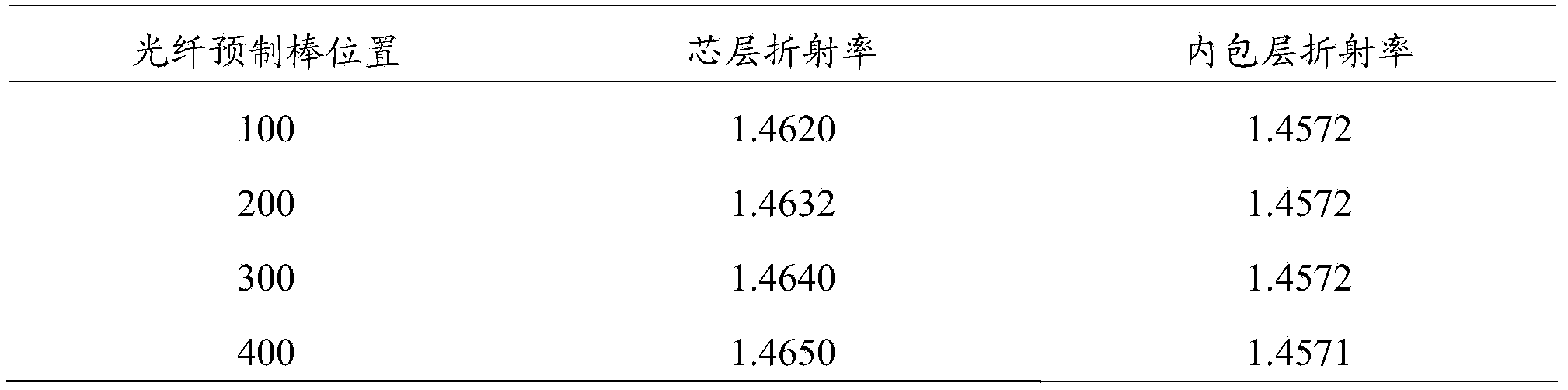

[0073] First, weld one end of the 400mm quartz deposition tube to the handle tube, then install the tail tube on the chuck on the other side, and weld the other end of the deposition tube to the tail tube after straightening; lock the tailstock to prevent the deposition process Move, move the upper limit and lower limit respectively to the corresponding position;

[0074] Start the recipe program, the PLC controls the computer to synchronize with the equipment, and runs in the order of etching, inner cladding deposition, pre-shrinking, and loose core layer deposition, in which the inner cladding layer is deposited 9 layers, the components are Si-F-P three systems, and the raw materials are SiCl respectively. 4 , SF 6 and POCl 3 , the deposition speed of the loose core layer is 140mm / min. After the deposition of the loose core layer is completed, the recipe program is closed. When the internal pressure drops to a negative value, the connection between the quartz deposition tub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com