A new production system and method for producing potassium chloride from carnallite

A production method and technology for carnallite, applied in the direction of alkali metal chlorides, etc., can solve the problems of high content, poor separation effect of potassium chloride and sodium chloride, and low recovery rate of potassium chloride system, so as to overcome the problems of system recovery. The effect of low rate, improving production process conditions and reducing washing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

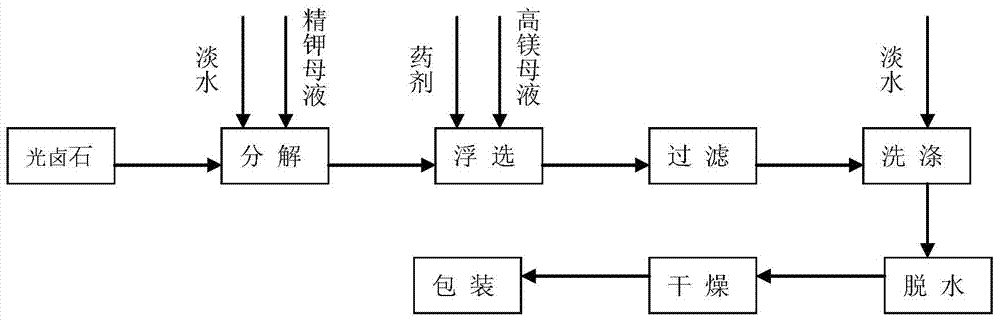

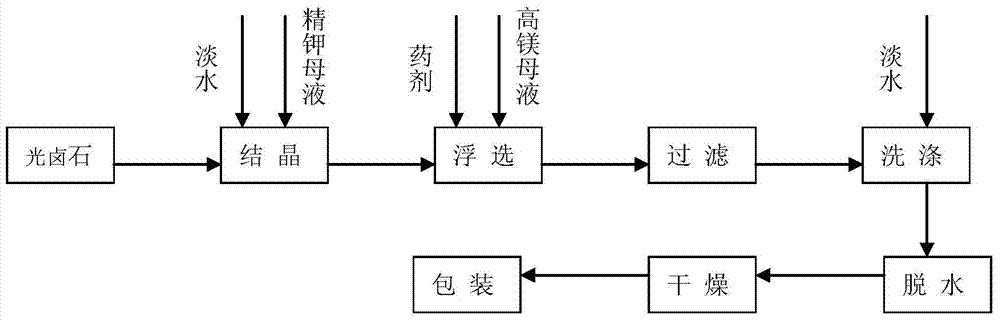

[0025] A new production system and method for producing potassium chloride from carnallite is a new production system and process for producing potassium chloride products from Yantian carnallite ore.

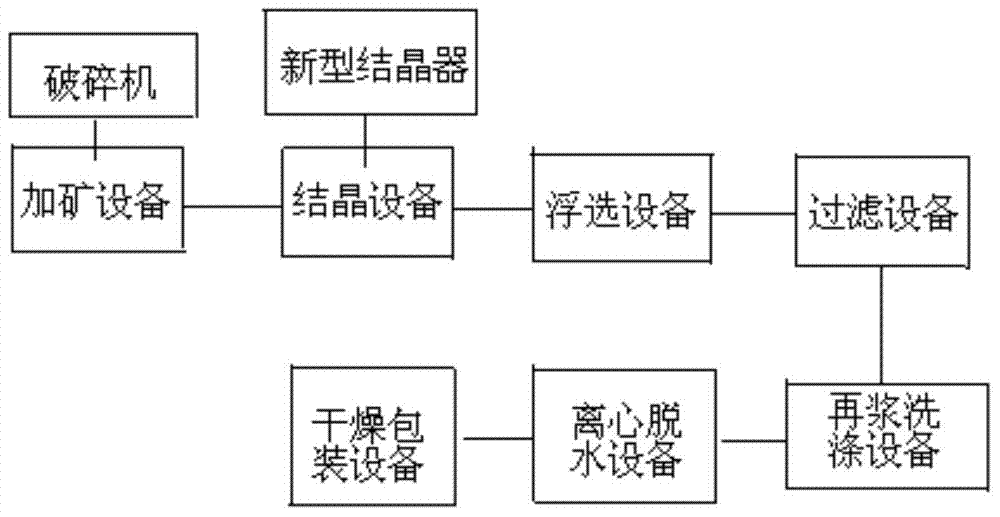

[0026] figure 2 Shown is a schematic diagram of the connection of the system equipment of the present invention, a new type of carnallite production potassium chloride production system, including mining equipment, crystallization equipment, flotation equipment, filtration equipment, repulping washing equipment, centrifugal dehydration equipment, dry packaging equipment , each device is connected sequentially;

[0027] Add a crusher to the above-mentioned mining equipment, so that the larger carnallite can be crushed and become smaller, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com