Ball-screw-driven lever-toggle lever secondary booster presses

A ball screw and press technology, which is applied to presses, stamping machines, manufacturing tools, etc., can solve the problems of large overall size of the press, poor mechanical properties of the press, and large impact force of the base, and achieve high energy utilization. , Low working noise and reduced structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

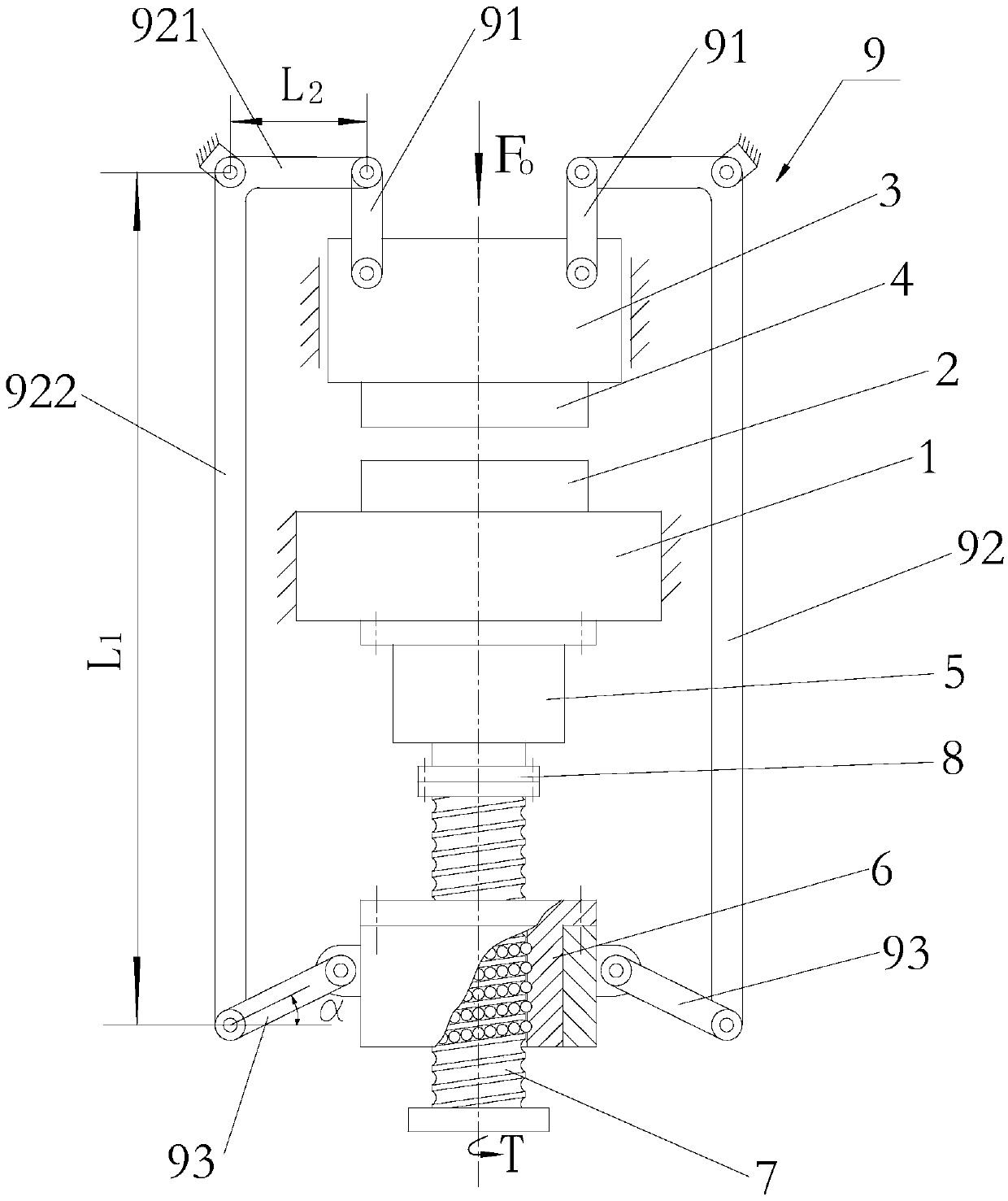

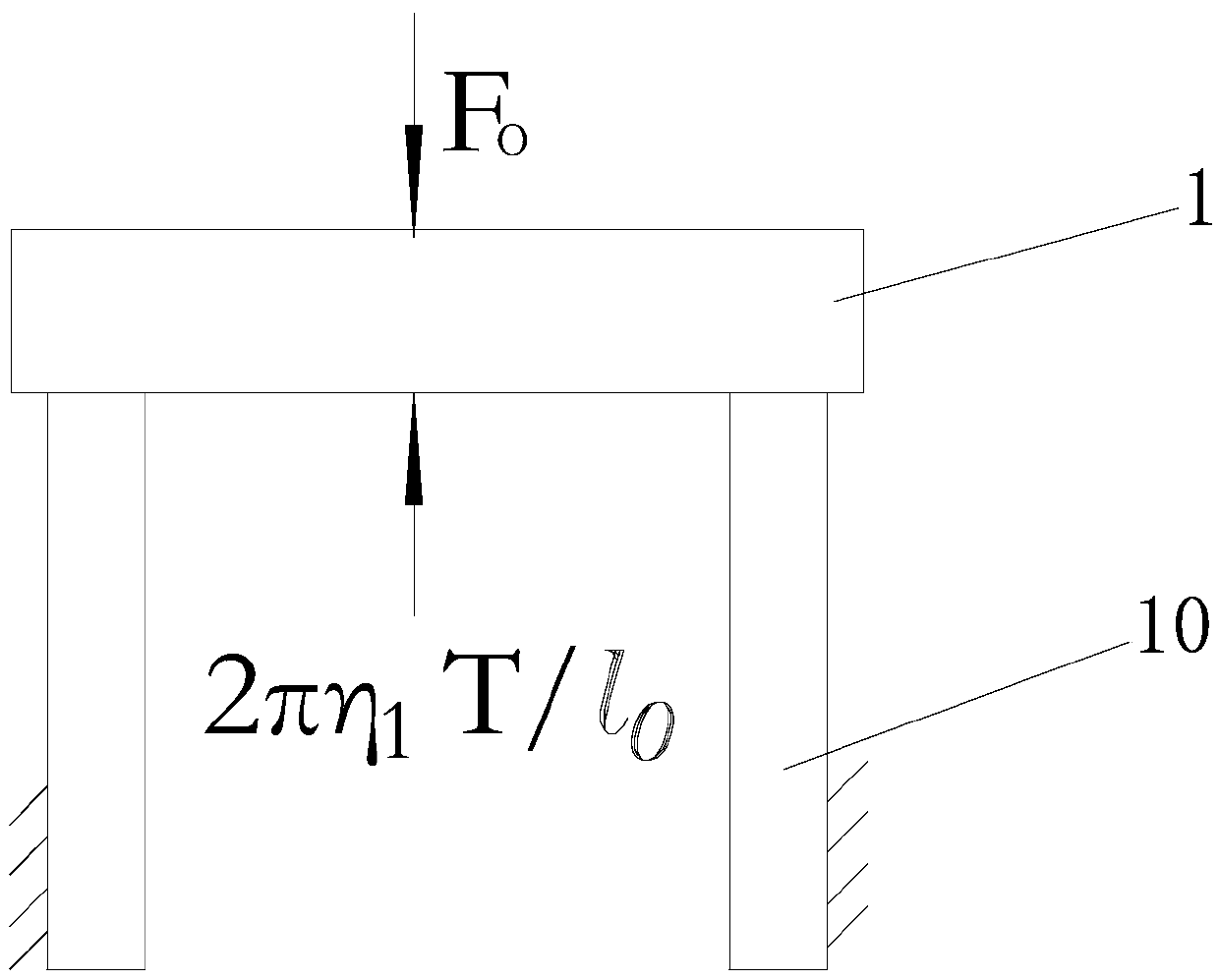

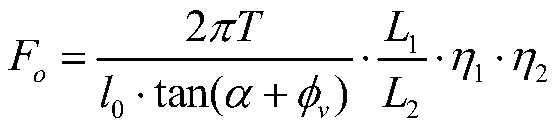

[0019] see figure 1 The press machine shown includes a workbench 1 fixedly arranged on the frame, and an upper die movement assembly which is slidably arranged on the frame up and down and located above the workbench 1 . In this embodiment, the upper mold movement assembly includes a slider 3 that can slide up and down on the frame, and an upper mold 4 that is fixedly arranged at the bottom of the slider 3 . It is the lower die 2 for punching and forming the workpiece to be processed. A track for the slide block 3 to slide up and down is set on the frame so that the slide block 3 can slide up and down along the track.

[0020] The press also includes a motor 5 fixedly installed under the workbench 1 , a lead screw 7 connected to the output shaft of the motor 5 , and a nut 6 sleeved on the lead screw 7 in a screw fit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com