Preparation method of metal-resin composite and metal-resin composite

A metal-resin and composite technology, applied in the field of materials, can solve problems such as singleness and insufficient bonding force between metal and resin, and achieve the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

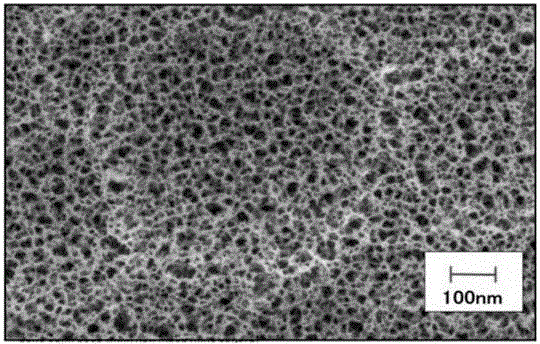

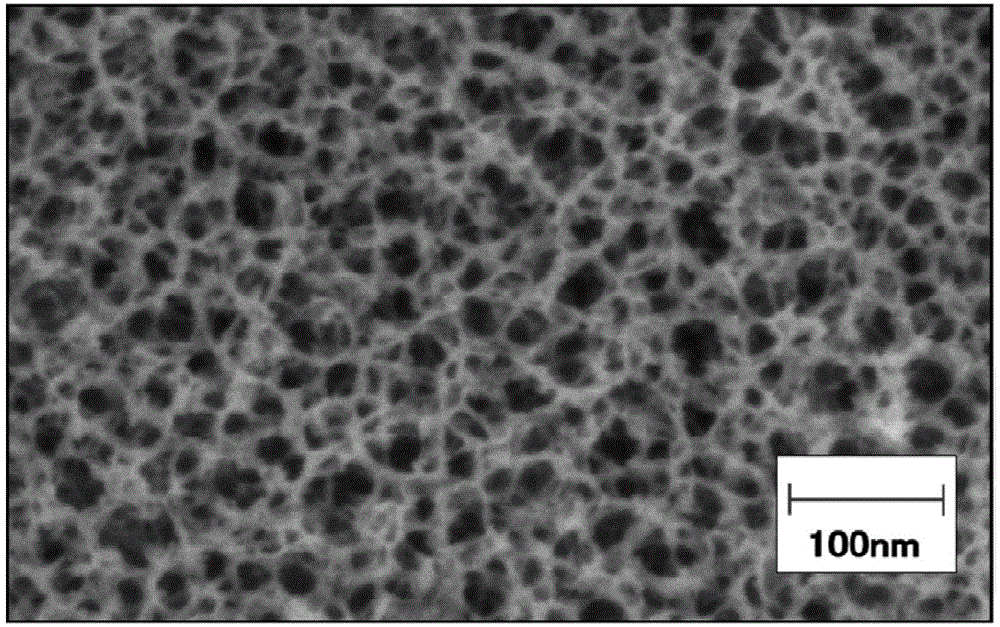

Image

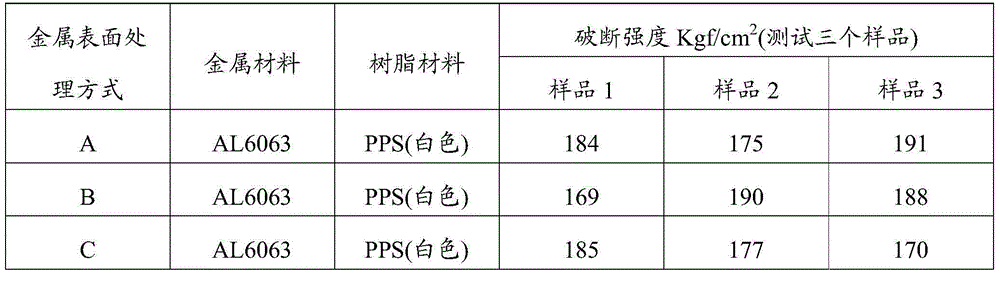

Examples

Embodiment 1

[0030] The preparation method of the metal-resin composite body includes the following steps: metal workpiece—oil removal and degreasing treatment—surface layer treatment for metal natural oxide removal—microporous treatment—nitrogen atom adsorption treatment—water washing and drying treatment—injection molding treatment—obtaining the metal resin composite body.

[0031] Specifically, degreasing is as follows: Ultrasonic treatment of CNC or punched metal workpieces at 40°C-60°C for 3-5 minutes, the ultrasonic power is 2-2.6KW, and the concentration of the ultrasonic liquid is 100-300g / L acid, alkali or organic solvent. This step is mainly for degreasing and degreasing. The ultrasonic power and concentration of ultrasonic liquid can remove as much grease as possible on the surface of the workpiece without corroding the metal workpiece body to prepare for the next step. The metal workpiece can be various metals such as copper, steel, titanium, magnesium, etc., or various metal ...

Embodiment 2

[0039] The preparation method of the metal-resin composite body includes the following steps: metal workpiece—oil removal and degreasing treatment—surface treatment for removing metal natural oxide—anodic oxidation treatment—microporous treatment—washing and drying treatment—injection molding treatment—obtaining the metal resin composite body.

[0040] Specifically, degreasing is as follows: Ultrasonic treatment of CNC or punched metal workpieces at 40°C-60°C for 3-5 minutes, the ultrasonic power is 2-2.6KW, and the concentration of the ultrasonic liquid is 100-300g / L acid, alkali or organic solvent. This step is mainly for degreasing and degreasing. The ultrasonic power and concentration of ultrasonic liquid can remove as much grease as possible on the surface of the workpiece without corroding the metal workpiece body to prepare for the next step. The metal workpiece can be various metals such as copper, steel, titanium, magnesium, etc., or various metal alloys, and aluminu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com