A cutting system with a vacuum stabilizing device

A voltage stabilizing device and cutting system technology, applied in grinding/polishing safety devices, grinding machine parts, grinding machines, etc. Unsmooth and other problems, to achieve the effect of enhancing the voltage stabilization effect, speeding up the falling, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

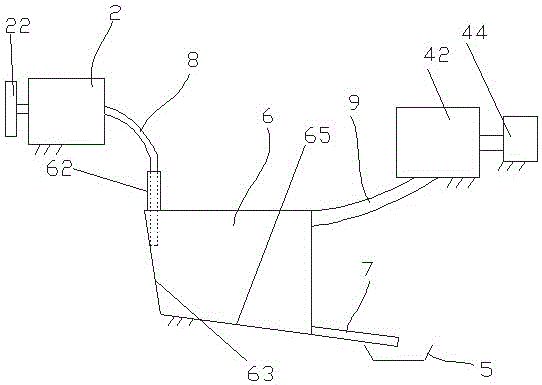

[0025] Such as figure 1 As shown, a cutting system with a vacuum stabilizing device includes a cutting machine 2 and a vacuuming device connected to the cutting machine 2, and also includes a vacuum stabilizing device connected to the cutting machine 2 and the vacuuming device.

[0026] The cutting machine 2 specifically includes a cutting tool (not shown) and a vacuum absorber 22 communicated with a vacuum device. Specifically, the vacuum absorber 22 may be a vacuum chuck. The vacuum suction cup is responsible for absorbing and fixing the material to be cut, and the cutting tool performs half-cut processing.

[0027] The vacuuming equipment includes a vacuum generator 42 and an air compressor 44 connected to the cutting machine 2 through a vacuum stabilizing device in sequence. After the air compressor 44 and the vacuum generator 42 are started, a negative pressure can be formed between the vacuum absorber 22 and the material to be cut, thereby absorbing the material to be c...

Embodiment 2

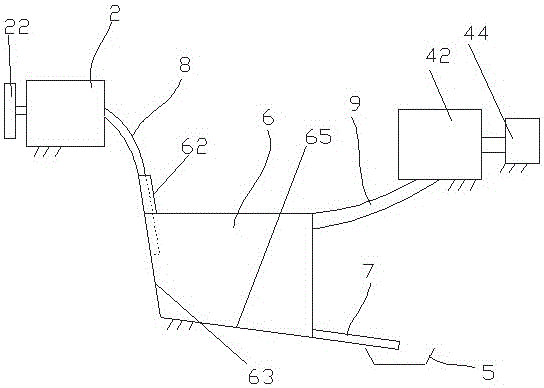

[0031] Such as figure 2 As shown, a cutting system with a vacuum stabilizing device differs from Embodiment 1 in that: the axis of the air inlet pipe 62 provided on the top of the casing 6 is parallel to the direction of inclination of the flow guide surface 63 and is close to the flow guide surface 63 set up. The first vacuum pipe 8 extends into the air intake pipe 62 and is connected with the air intake pipe 62 , while the lower end exposes the air intake pipe 62 and adjoins the guide surface 63 .

[0032] During operation, the coolant flows from the first vacuum pipe 8 extending into the intake pipe 62 to the guide surface 63, and the flow angle remains constant, falling continuously, smoothly and quickly.

Embodiment 3

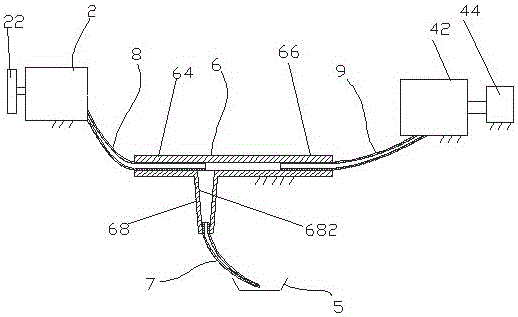

[0034] Such as image 3 As shown, a cutting system with a vacuum stabilizing device differs from Embodiment 1 in that: the housing 6 is in the shape of a three-way pipe, including a first branch pipe 64 and a second branch pipe 66 whose axes are respectively horizontal, and also includes The third branch pipe 68 in the vertical direction. The first, second and third branch pipes 64, 66 and 68 communicate with each other, and the axes of the first and second branch pipes 64 and 66 are on the same horizontal line. The nozzle of the first branch pipe 64 is an air inlet, and the cutting machine 2 is connected to the first branch pipe 64 by the first vacuum tube 8, and the first vacuum pipe 8 stretches into the first branch pipe 64 to the nozzle and is positioned above the nozzle of the third branch pipe 68; The nozzle of the second branch pipe 66 is an air outlet, and the vacuum equipment is connected to the second branch pipe 66 by a second vacuum tube 9; Conical funnel shape, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com