Sulfur modified chloroprene rubber and method for producing same, and molded body

A chloroprene rubber, sulfur modification technology, applied in the direction of mechanical equipment, transmission belt, V-belt, etc., can solve the problems of peeling, shear deformation, shear stress increase, flying out, etc., to improve the bonding performance , the effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0032]

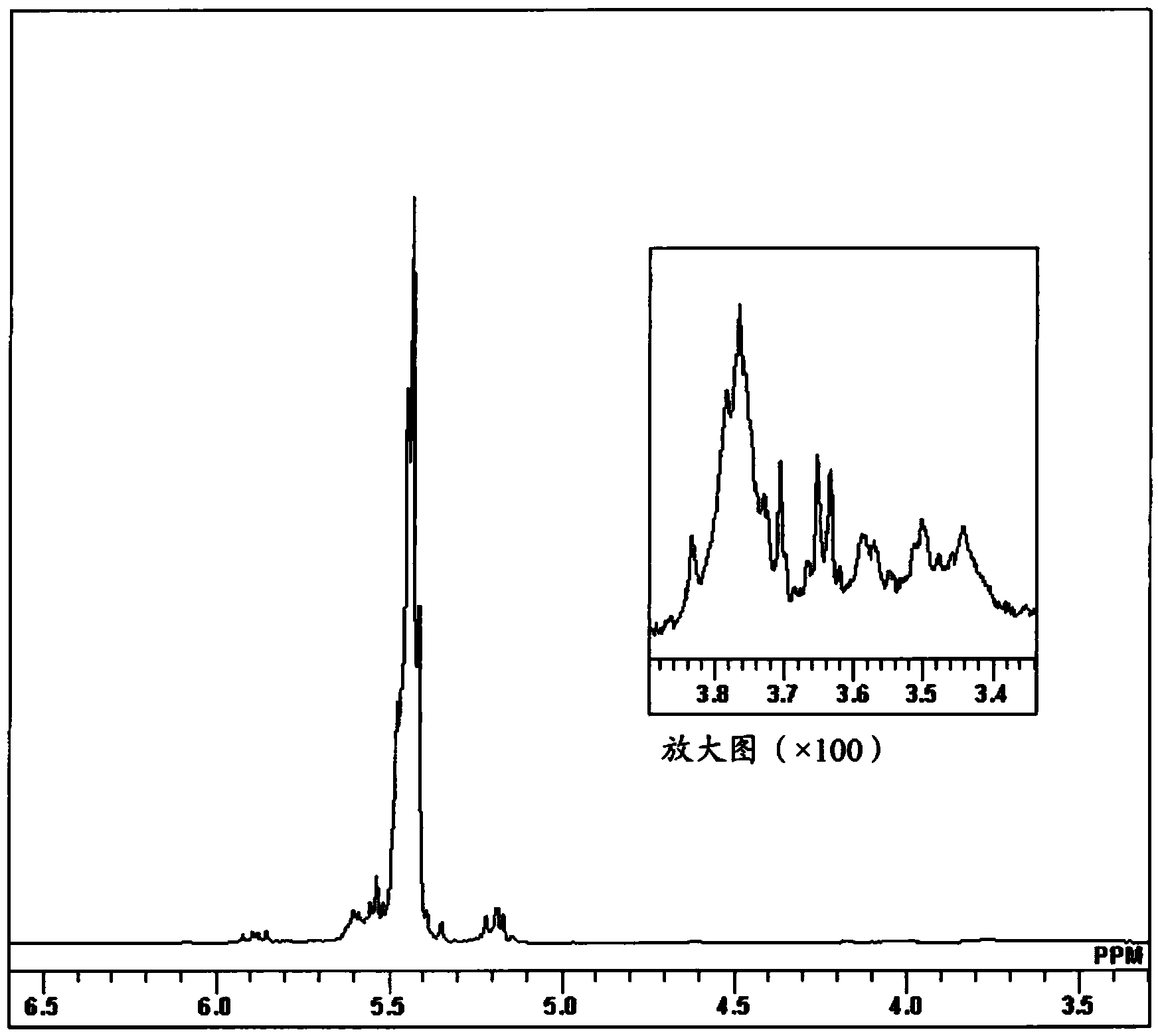

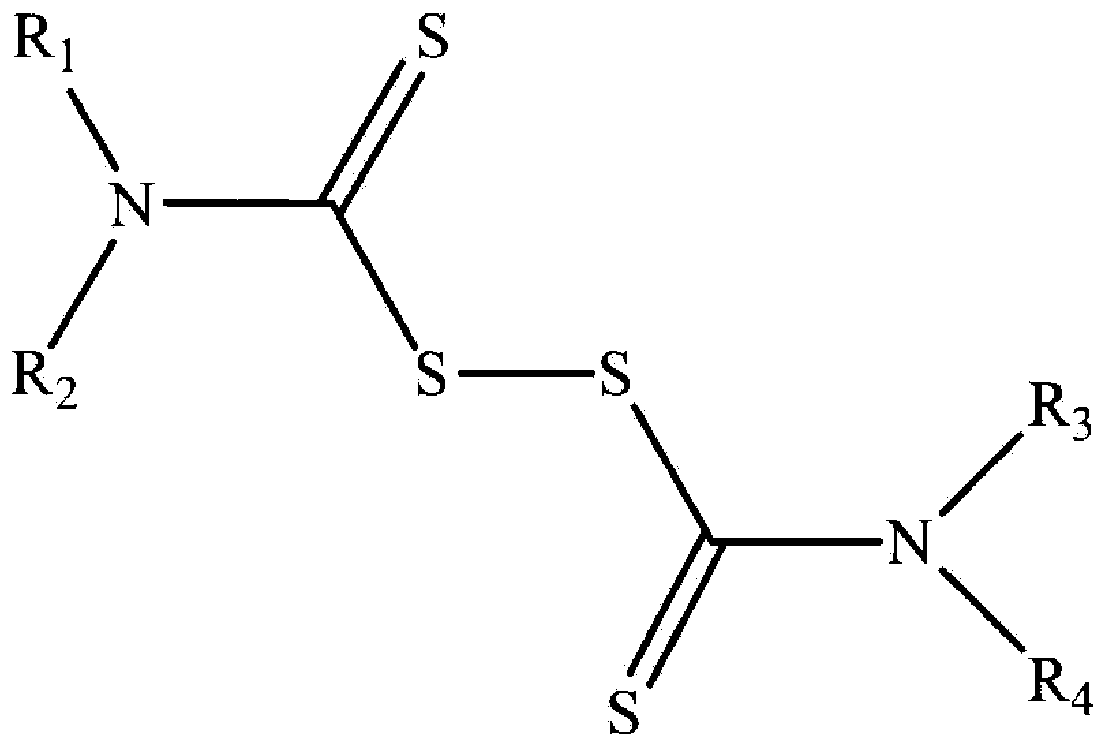

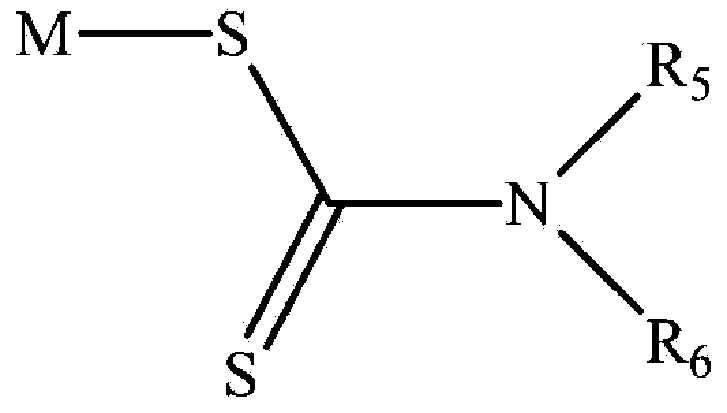

[0033] First, the sulfur-modified chloroprene rubber of the first embodiment of the present invention will be described. In the sulfur-modified chloroprene rubber of this embodiment, in the presence of sulfur, 2-chloro-1,3-butadiene (hereinafter referred to as chloroprene) alone is subjected to emulsion polymerization, or chloroprene The polymer is obtained by emulsion polymerization of olefin and other monomers, and the end of the polymer is modified by tetramethylthiuram disulfide.

[0034] Specifically, the sulfur-modified chloroprene rubber of the present embodiment is obtained by performing a polymerization step and a plasticizing step. The polymerization step is to mix 100 parts by mass of chloroprene with 0.1 to 2.0 mass parts. Parts of sulfur, and if necessary, less than 50 parts by mass of monomers other than chloroprene are mixed, and the emulsion polymerization is carried out until the monomer conversion rate is in the range of 60 to 90%; the plasticizing step...

no. 2 approach

[0092] Next, the molded body of the second embodiment of the present invention will be described. The molded body of this embodiment is formed by molding the sulfur-modified chloroprene rubber of the first embodiment, and embedding core wires or reinforcing fiber materials to form a composite. Since the molded body of the present embodiment uses the sulfur-modified chloroprene rubber of the first embodiment with excellent adhesive performance, the rubber material has excellent adhesiveness with the core wire or the reinforcing fiber material. Therefore, it is suitable for use in rubber products containing reinforced materials such as transmission belts or conveyor belts for automobiles and general industrial use.

[0093] In addition, the adhesive force between the rubber material and the core wire or reinforced fiber material can be measured in accordance with the H test described in ASTM D2138-72. In the "H test", an H-shaped test piece in which a fiber rope is embedded in a v...

Embodiment 1

[0097]

[0098] (a) First, in a polymerization tank with an inner volume of 30 liters, 100 parts by mass of chloroprene (2-chloro-1,3-butadiene), 2,3-dichloro-1,3- Butadiene 3.0 parts by mass, sulfur 0.50 parts by mass, pure water 120 parts by mass, potassium disproportionated rosinate (manufactured by Harima Chemicals Group, Inc.) 3.80 parts by mass, sodium hydroxide 0.59 parts by mass, β-naphthalenesulfonate formaldehyde 0.5 parts by mass of the sodium salt of forest condensate (trade name Demol N: manufactured by Kao), and adjusted to an aqueous emulsion. In addition, the pH of the aqueous emulsion at the start of polymerization was 12.8.

[0099] To this aqueous emulsion, 0.1 parts by mass of potassium persulfate was added as a polymerization initiator, and emulsion polymerization was performed under a nitrogen stream at a polymerization temperature of 40°C. In addition, at the time when the conversion rate became 75%, diethylhydroxylamine was added as a polymerization inhib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com