Slipstream for reliable anode-to-cathode flow in freezing conditions

An anode and cathode technology, applied in electrical components, fuel cells, electrochemical generators, etc., can solve problems such as the effect of orifice ice clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

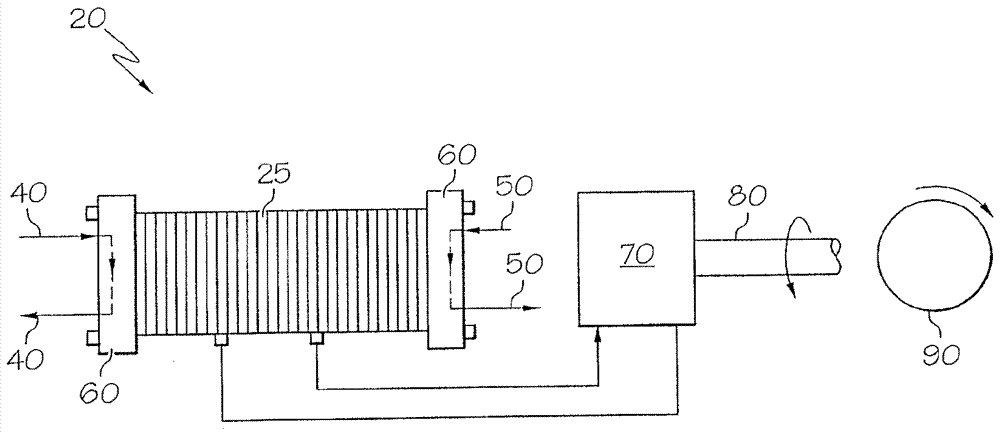

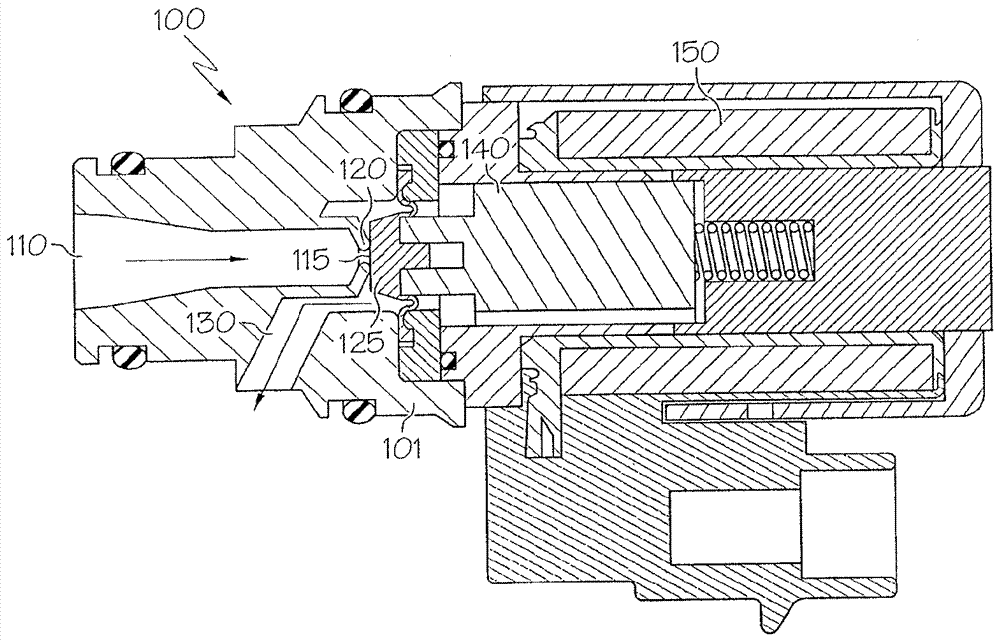

[0052] First refer to Figure 1A to Figure 1C , the vehicle 1 includes a propulsion source in the form of a fuel cell system 10 having one or more fuel cell stacks 20 , the stacks 20 being fueled from one or more fuel tanks 30 . In one form, the fuel is in the form of a hydrogen-based first reactant. The second reactant (eg, an oxygen-based fluid) may be provided from the ambient environment. Either or both reactants may be provided to fuel cell system 10 in pressurized form, such as with a compressor, pump, or related device (not shown). Although not shown, additional sources of propulsion, such as a conventional internal combustion engine (ICE) or a battery pack, may also be utilized to provide hybrid propulsion properties to the vehicle 1 .

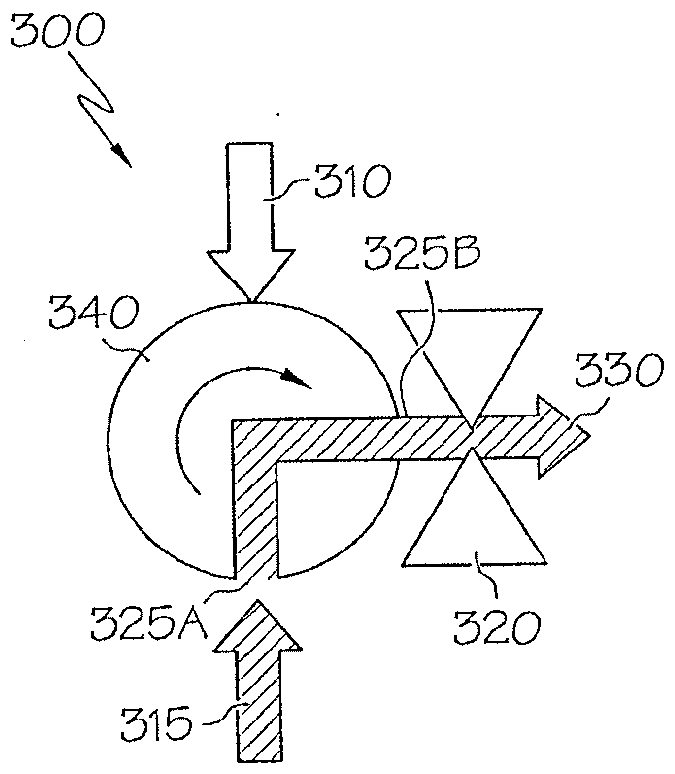

[0053] still refer to Figure 1A to Figure 1C , the fuel cell stack 20 is composed of a number of individual fuel cells 25 which in turn are composed of an anode 25A, a cathode 25B and a proton transport membrane 25C. The first r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com