Carbon-coated nickel-cobalt lithium manganate positive electrode material and preparation method thereof

A technology of nickel cobalt lithium manganate and lithium cobalt manganate is applied in the field of lithium battery cathode material preparation, and can solve the problems of poor electrical conductivity and difficult control of nickel cobalt lithium manganate cathode material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

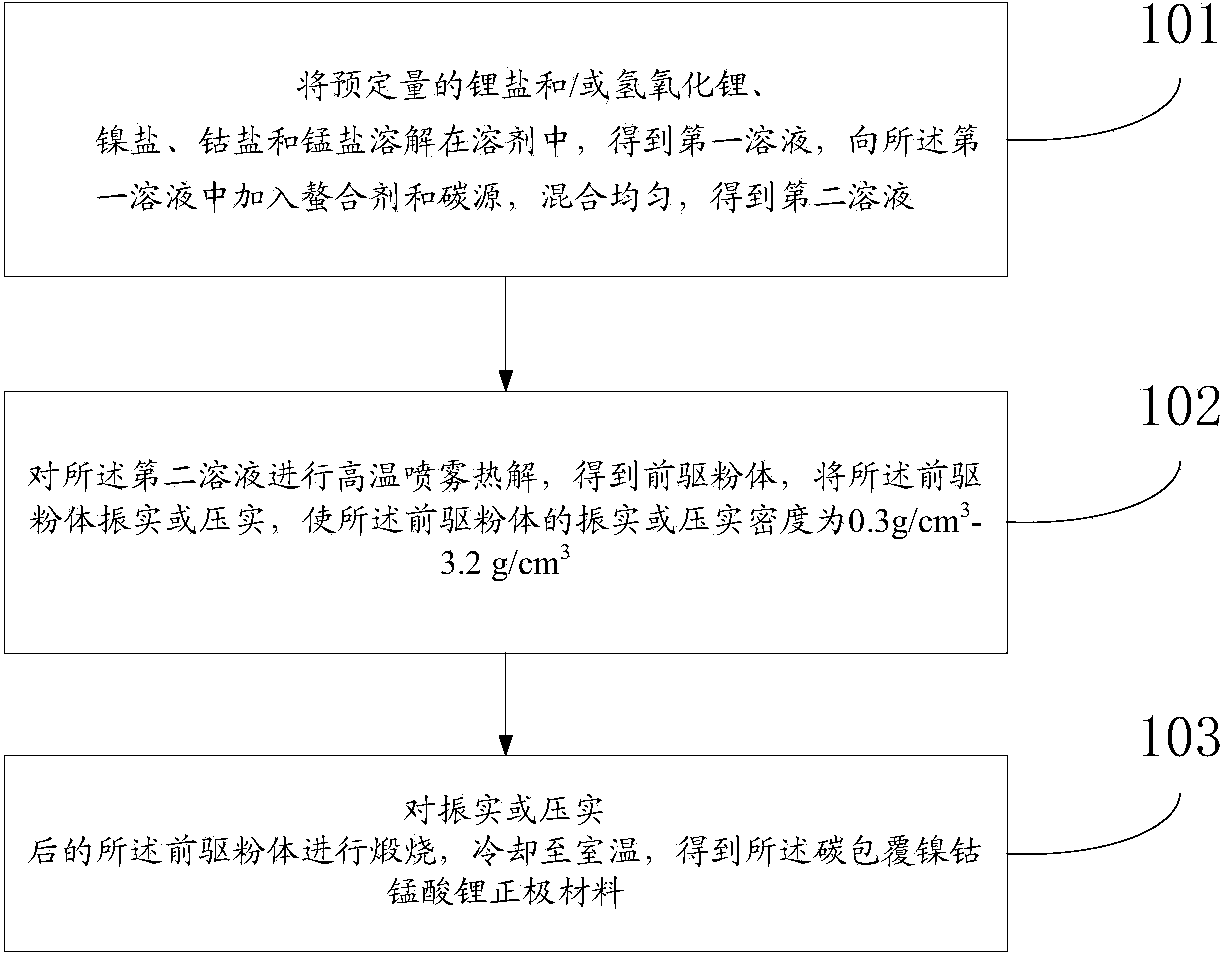

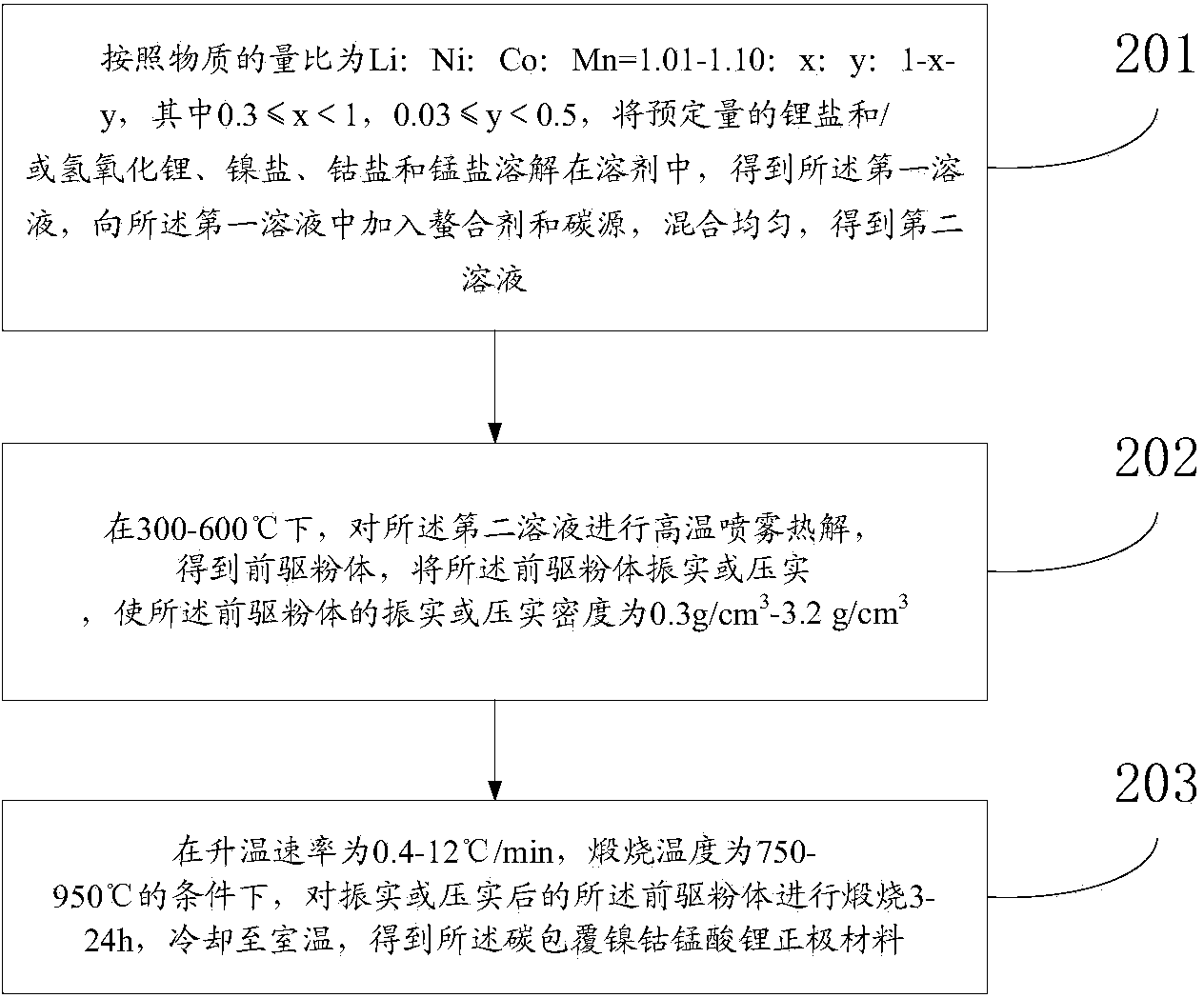

[0064] In the third aspect, the embodiment of the present invention provides an embodiment of a method for preparing a carbon-coated nickel-cobalt lithium manganese oxide positive electrode material. figure 1 It is a flow chart of the method of this embodiment. as attached figure 1 As shown, the method includes:

[0065] Step 101, dissolving a predetermined amount of lithium salt and / or lithium hydroxide, nickel salt, cobalt salt and manganese salt in a solvent to obtain a first solution, adding a chelating agent and a carbon source to the first solution, and mixing uniformly , to obtain the second solution.

[0066] Step 102, performing high-temperature spray pyrolysis on the second solution to obtain a precursor powder, and vibrating or compacting the precursor powder so that the vibration or compaction density of the precursor powder is 0.3 g / cm 3 -3.2g / cm 3 .

[0067] Step 103, calcining the vibrated or compacted precursor powder, and cooling to room temperature to ob...

Embodiment 1

[0084] The embodiment of the present invention provides a method for preparing a carbon-coated nickel-cobalt-lithium manganese oxide composite positive electrode material, comprising the following steps:

[0085] 1) Accurately weigh a certain amount of Lithium Nitrate, Nickel Acetate, Cobalt Acetate, Manganese Acetate according to the amount ratio Li:Ni:Co:Mn=3.12:1:1:1, the solvent is deionized water, ethanol mixed solution ( The mass ratio of deionized water to ethanol is 1:1) to form a uniform solution. Add citric acid chelating agent and glucose carbon source, perform magnetic stirring to disperse evenly, and obtain a transparent mixed solution. Then, the solution is subjected to high-temperature spray pyrolysis with a pyrolysis temperature of 350° C. to obtain a precursor powder material.

[0086] 2) Vibrate the precursor powder material so that the tap density is 0.8g / cm 3 , and then sintered in an air atmosphere with programmed temperature control, heated to 800°C at ...

Embodiment 2

[0090] The embodiment of the present invention provides a method for preparing a carbon-coated nickel-cobalt-lithium manganese oxide composite positive electrode material, comprising the following steps:

[0091] 1) Accurately weigh a certain amount of lithium acetate, nickel nitrate, cobalt chloride, and manganese chloride according to the ratio of the substances Li:Ni:Co:Mn=1.06:0.3:0.3:0.4, and the solvent is ethanol to make a solution. Add triethanolamine chelating agent and phenolic resin carbon source, carry out ball milling to disperse evenly, and obtain a transparent mixed solution. Then, the solution is subjected to high-temperature spray pyrolysis with a pyrolysis temperature of 600° C. to obtain a precursor powder material.

[0092] 2) Compact the above-mentioned precursor powder material so that the compacted density is 2.5g / cm 3 , and then sintered in a temperature-programmed air atmosphere, heated to 950°C at a heating rate of 5°C / min, calcined for 6h, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com