High-density stackable packaging structure and manufacturing method

A technology of packaging structure and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of precision deviation, affecting the placement yield, and sliding of the upper sphere, and achieves improved reliability and denser Excellent performance, avoid short circuit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

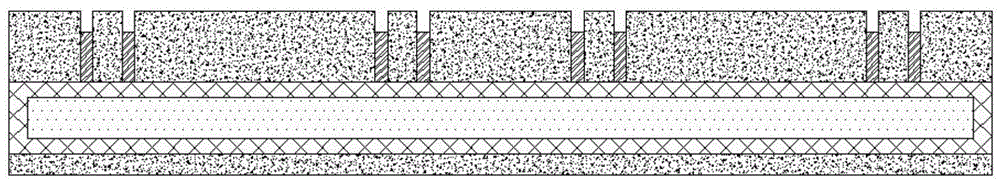

[0047] see Figure 10 , a high-density stackable packaging structure of the present invention, which includes a metal lead frame or substrate 5, a chip 3 is mounted on the front side of the metal lead frame or substrate 5, copper pillars 2 are arranged around the chip 3, and the copper The top of the column 2 is provided with a tin column 4, and the peripheral area of the copper column 2, the chip 3 and the tin column 4 is encapsulated with a plastic encapsulant 1, the height of the plastic encapsulant 1 exceeds the height of the tin column 4, and the top of the tin column 4 The area is provided with mounting holes 6 .

[0048] Its production method is as follows:

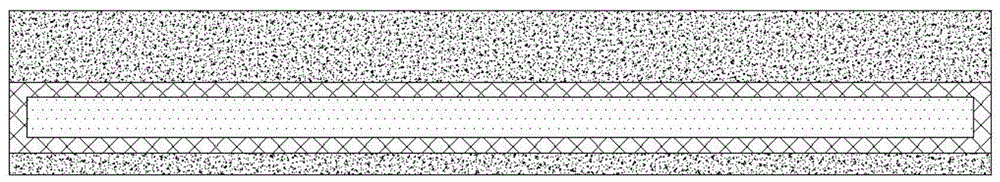

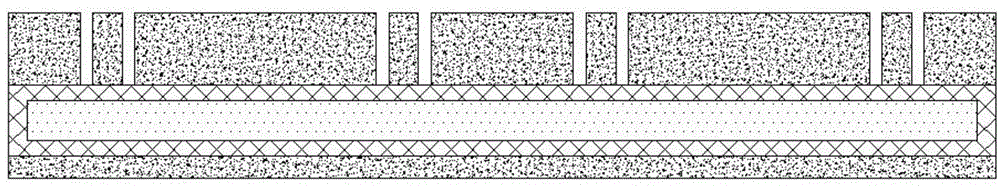

[0049] Step 1. Take the metal lead frame or the surface of the substrate and paste the photoresist film

[0050] see figure 1 , take a piece of metal lead frame or substrate with appropriate thickness, and paste a photoresist film that can be exposed and developed on the front and back respectively, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com