Magnet superconducting line winding controller

A control device, superconducting wire technology, applied in coil manufacturing, inductor/transformer/magnet manufacturing, transportation and packaging, etc. The effect of simple structure, reduced expenditure and convenient manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further explained below in conjunction with the accompanying drawings.

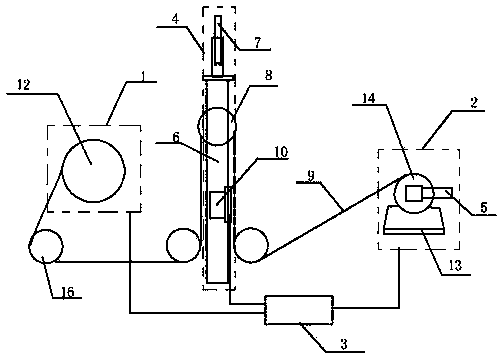

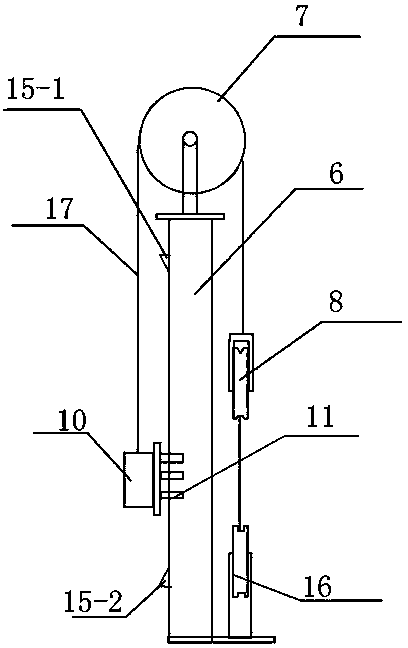

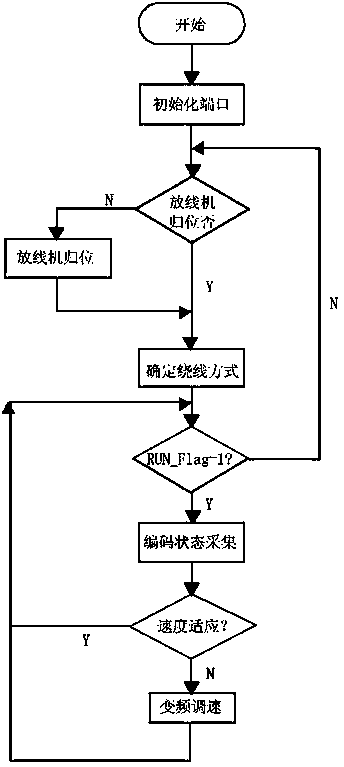

[0022] Such as Figure 1-2 As shown, a magnet superconducting wire winding control device includes a winding system 1 , a tension control system and a pay-off system 2 in sequence. The winding system 1 includes a winding frame 12 and a speed regulating device 5 , and the speed regulating device 5 adjusts the winding speed of the winding frame 12 . The tension control system includes a tension control device 3, a tension detection device 4 and a speed regulating device 5, and the tension control device 3 is an AT89C52 single-chip microcomputer. The speed regulating device 5 is a DC motor. The tension detection device 4 includes a column 6, a wire passing wheel 7, a tensioning wheel 8 and an encoder. The wire passing wheel 7 is arranged at one end of the column 6, and the tensioning wheel 8 is movable on one side of the column 6. The encoder includes a weight box 10 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com