Flame detection device

A flame detection and detector technology, which is applied in the field of safety monitoring devices, can solve the problems of unsatisfactory sealing performance and the reliability to be improved, and achieves the effect of being beneficial to the service life and accuracy and ensuring the sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

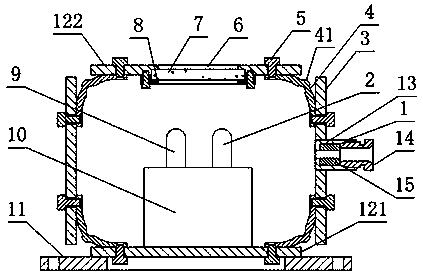

[0027] Such as figure 1 , a flame detection device, comprising a casing in the form of a box and a flame detection assembly arranged in the casing, the casing includes a side wall 3 constituting the side of the casing, a bottom plate 121 constituting the bottom surface of the casing, and a The cover plate 122 and the two flexible connecting rings 4 respectively connecting the side wall 3 and the bottom plate 122, connecting the side wall 3 and the cover plate 121, the flexible connecting ring 4 is annular, and any point on the flexible connecting ring 4 is on the flexible connecting ring 4. The section in the height direction is in the shape of an arc plate; the side wall 3 or the cover plate 122 is also provided with a glass 7 for the passage of light; the flame detection assembly includes any one of the infrared detector 2 or the ultraviolet detector 9 ; The side wall 3 or the cover plate 122 is also provided with a threading pipe 1 for the cable to pass through the shell, a...

Embodiment 2

[0030] The present embodiment is further limited on the basis of embodiment 1, as figure 1 , in order to facilitate the installation and disassembly of the glass 7 on the present invention, to facilitate the assembly and maintenance of the present invention, it also includes a glass fixing seat 8 that is bolted to the side wall 3 or the cover plate 122, and the side wall 3 or the cover plate 122 is provided with a glass clamping groove, and the glass 7 is clamped in the glass clamping groove through the glass fixing seat 8 . The above arrangement makes the glass 7 be detachably connected on the side wall 3 or the cover plate 122 .

Embodiment 3

[0032] The present embodiment is further limited on the basis of embodiment 1, as figure 1 , in order to facilitate the processing, manufacturing and assembly of the present invention, it also includes a plurality of connecting bolts 5, and the flexible connecting ring 4 is connected with the cover plate 122, the bottom plate 121 and the side wall 3 through the connecting bolts 5 and the flexible connecting ring 4. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com