Spot welded fiber grating strain sensor and its installation method

A technology of strain sensor and optical fiber grating, which is applied in the field of sensors, can solve problems such as reduced stability, short welding distance, and corrosion of sensitive grids, and achieve the effects of improving measurement accuracy, long service life, and anti-electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

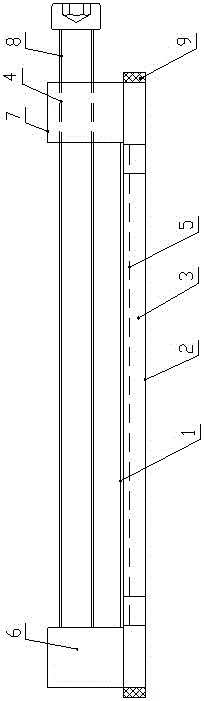

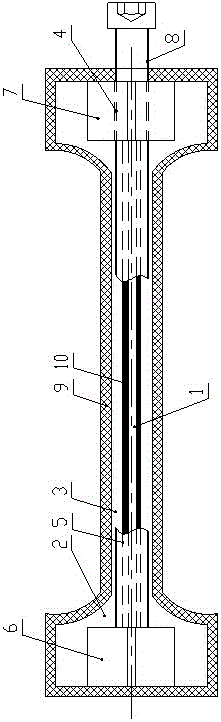

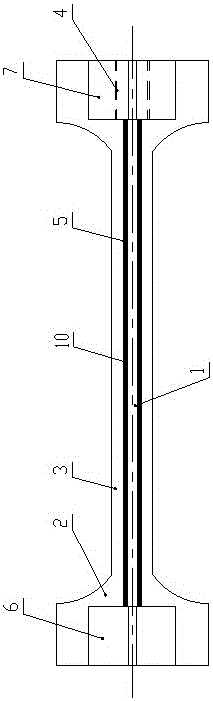

[0033] Such as figure 1 As shown, the present invention includes a fiber grating strain sensor 1 and a base body 2. The base body 2 is made of a highly elastic alloy material. The base body 2 includes a base plate 3 and two adjustment blocks integrally connected to the left and right ends of the base plate 3. The two adjustment blocks are respectively left adjustment blocks. Block 6, right adjustment block 7, a base body groove 5 is provided in the middle part of the base body 3 between the two adjustment blocks, and the fiber grating strain sensor 1 is installed in the base body groove 5. There is a layer of encapsulation layer 10 on the outside of the grating strain sensor 1, and the material of the encapsulation layer 10 is glass powder with low melting point. The lower half of the encapsulation layer 10 is connected to the groove 5 of the substrate, thereby encapsulating the grating strain sensor 1 .

[0034] Adjustment hole 4 is horizontally arranged on right adjustment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com