Low pressure pipeline mounting process used in 300m<2> sintering low temperature waste heat power generation system

A technology for low-pressure pipelines and power generation systems, applied in pipeline laying and maintenance, non-detachable pipe connections, pipes/pipe joints/fittings, etc., which can solve problems such as pipeline laying and installation processes that cannot meet pipeline requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] for 300m 2 The low-pressure pipeline installation process in the sintered low-temperature waste heat power generation system includes the following steps,

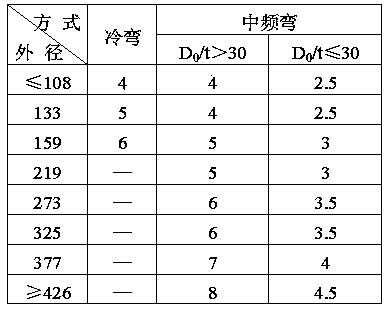

[0089] Preparation of pipes, pipe fittings and pipe accessories: (a) pipe bend: heat the pipe, use pipe bending equipment to clamp the pipe for bending, the outer diameter of the pipe D o is 520mm, wall thickness S 50mm, bending radius R 2600mm, bending angle θ 100°, the roundness of the curved part is equal to 7% of the outer diameter of the medium and low pressure pipes, and the angle deviation after bending is +0.5 ° , the measured wall thickness of the outer arc part of the elbow is equal to the minimum wall thickness of the straight pipe;

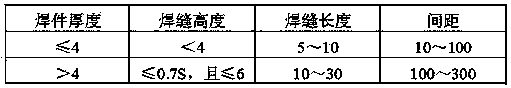

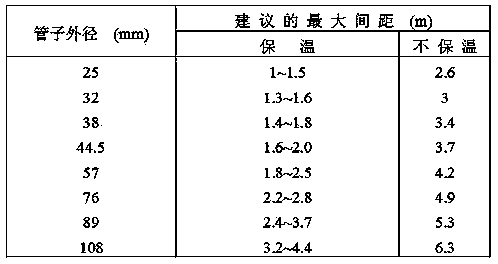

[0090] (b) Production of support and hanger: The angle steel is fixed together according to the design drawing by welding, and the spring is fixed between the angle steel in the vertical direction as a part for supporting and hoisting the pipeline. The deviation of the n...

Embodiment 2

[0101] for 300m 2 The low-pressure pipeline installation process in the sintered low-temperature waste heat power generation system includes the following steps,

[0102] Preparation of pipes, pipe fittings and pipe accessories: (a) pipe bend: heat the pipe, use pipe bending equipment to clamp the pipe for bending, the outer diameter of the pipe D o is 420mm, wall thickness S 40mm, bending radius R 2000mm, bending angle θ 70°, the roundness of the curved part is 6% of the outer diameter of the medium and low pressure pipe, and the angle deviation after bending is +0.2 。 , the measured wall thickness of the outer arc part of the elbow is greater than the minimum wall thickness of the straight pipe;

[0103] (b) Production of support and hanger: The angle steel is fixed together according to the design drawing by welding, and the spring is fixed between the angle steel in the vertical direction as a part for supporting and hoisting the pipeline. The deviation of the number o...

Embodiment 3

[0114] for 300m 2 The low-pressure pipeline installation process in the sintered low-temperature waste heat power generation system includes the following steps,

[0115] Preparation of pipes, pipe fittings and pipe accessories: (a) pipe bend: heat the pipe, use pipe bending equipment to clamp the pipe for bending, the outer diameter of the pipe D o is 400mm, wall thickness S 38mm, bending radius R 1800mm, bending angle θ 65°, the roundness of the curved part is 5.8% of the outer diameter of the medium and low pressure pipe, and the angle deviation after bending is 0 。 , the measured wall thickness of the outer arc part of the elbow is greater than the minimum wall thickness of the straight pipe;

[0116] (b) Production of support and hanger: The angle steel is fixed together according to the design drawing by welding, and the spring is fixed between the angle steel in the vertical direction as a part for supporting and hoisting the pipeline. The deviation of the number of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com