Method for preparing bio-oil and synthesis gas from biomass

A technology of biomass oil and biomass, which is applied in the preparation of liquid hydrocarbon mixtures, the manufacture of combustible gases, and the petroleum industry, and can solve the problems of separately preparing biomass oil or syngas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This example is used to illustrate the method of the present invention for preparing biomass oil and synthesis gas from biomass.

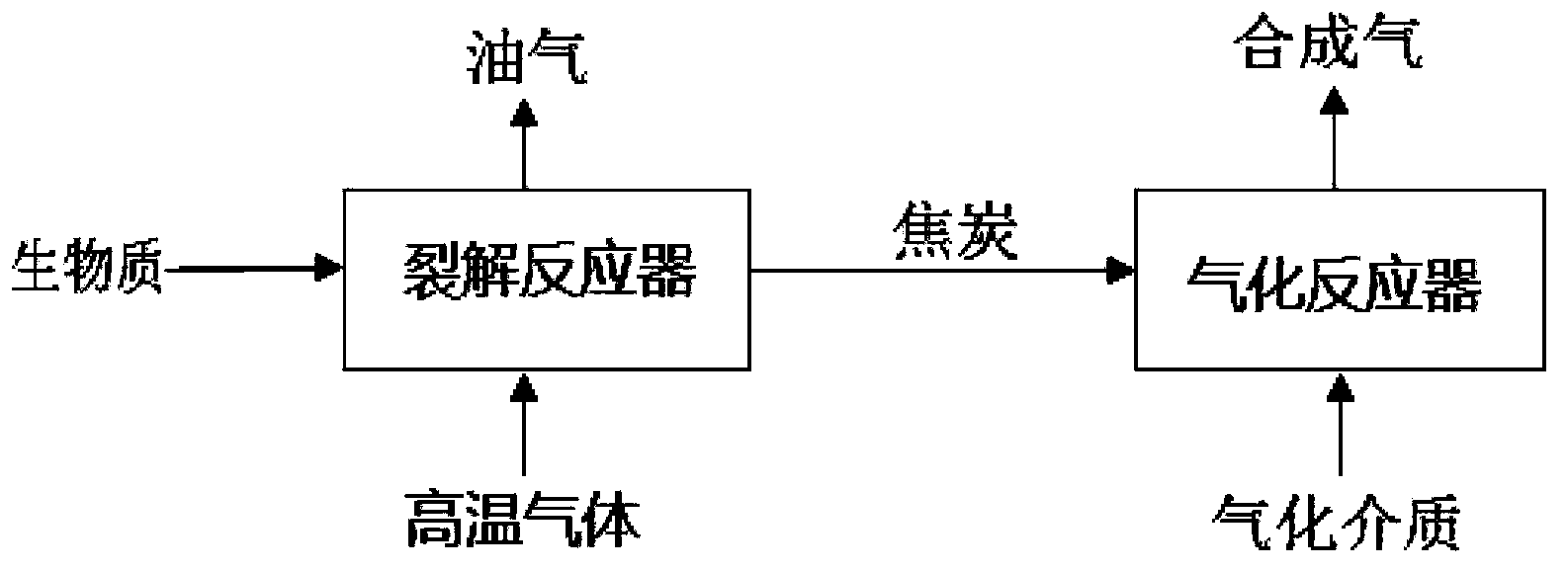

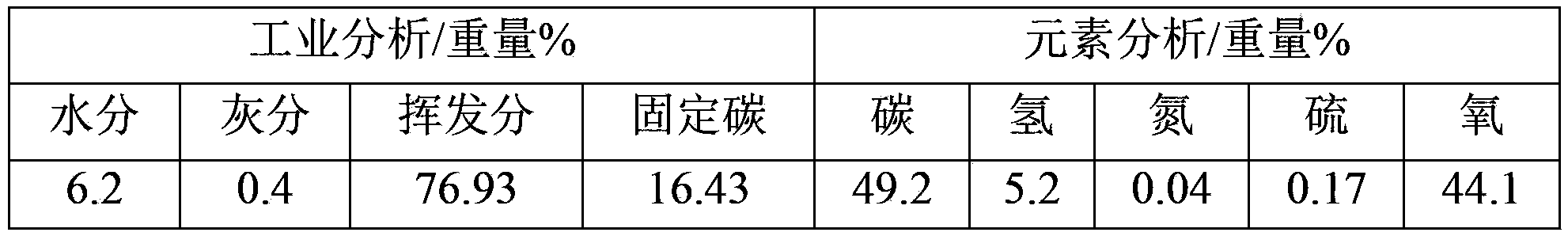

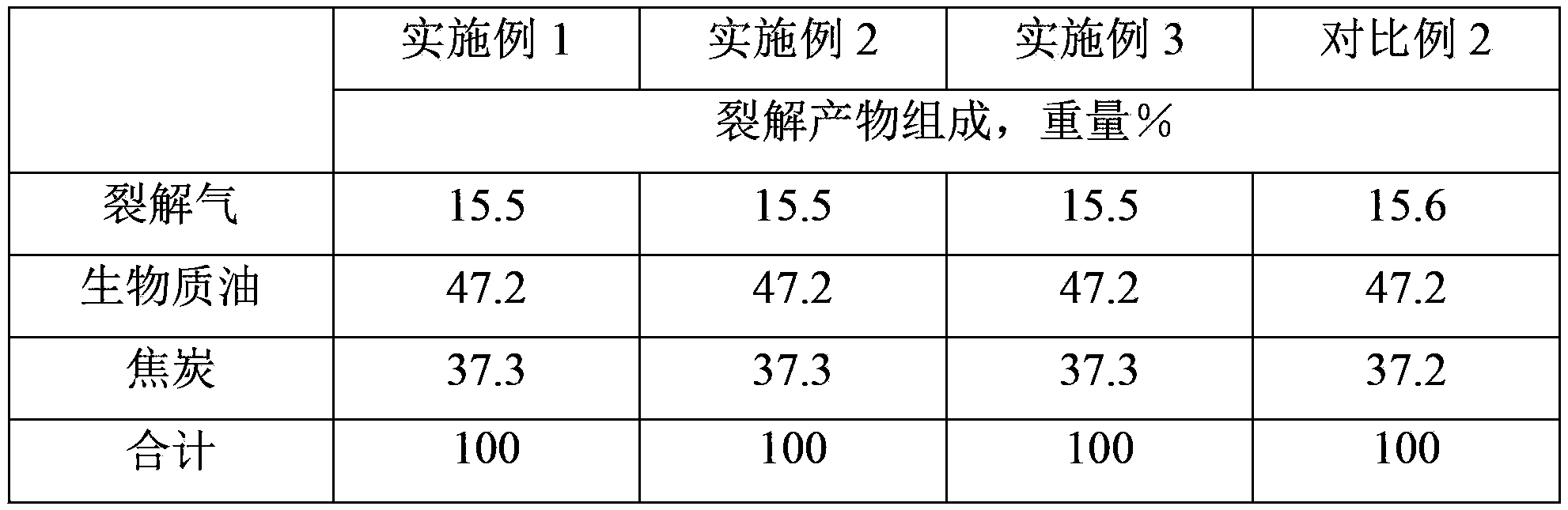

[0034] Such as figure 1 As shown, sawdust (particle size 0.07-2 mm, composition shown in Table 1 below) as biomass is heated to 150°C, then added to the fluidized bed cracking reactor, and contacted with the high temperature gas from the burner, control The bed temperature of the reactor was 500°C, and the reaction was carried out at 0.2 MPa for 10 minutes. After being processed by a fluidized bed cracking reactor, oil and gas and coke are obtained, and the oil and gas are introduced into the subsequent oil and gas separation system to separate cracked gas and biomass oil. Coke is introduced into the gasification reactor, and a mixture of 50 parts by weight of steam and oxygen (600°C) based on 100 parts by weight of coke is introduced into the gasification reactor, where the moles of steam and oxygen are 6:1, the gasification reaction is carr...

Embodiment 2

[0038] This example is used to illustrate the method of the present invention for preparing biomass oil and synthesis gas from biomass.

[0039] Sawdust (particle size 0.07-2 mm, composition as shown in Table 1 above) as biomass is heated to 150 ℃, and then added to the fluidized bed cracking reactor, and contact with the high temperature gas from the burner to control the reactor bed The layer temperature was 400°C, and the reaction was carried out at 0.1 MPa for 5 minutes. After being processed by a fluidized bed cracking reactor, oil and gas and coke are obtained, and the oil and gas are introduced into the subsequent oil and gas separation system to separate cracked gas and biomass oil. Coke is introduced into the gasification reactor, and 50 parts by weight of steam and oxygen mixed gas (200°C) based on 100 parts by weight of coke is introduced into the gasification reactor, where the moles of steam and oxygen are 6:1, the gasification reaction is carried out at 800°C and 0...

Embodiment 3

[0041] This example is used to illustrate the method of the present invention for preparing biomass oil and synthesis gas from biomass.

[0042] Such as figure 1 As shown, sawdust (particle size of 0.07-2 mm, composition as shown in Table 1 above) as biomass is heated to 150°C, then added to a fluidized bed cracking reactor, and contacted with high-temperature gas from the burner to control The bed temperature of the reactor was 600°C, and the reaction was carried out at 0.2 MPa for 5 minutes. After being processed by a fluidized bed cracking reactor, oil and gas and coke are obtained, and the oil and gas are introduced into the subsequent oil and gas separation system to separate cracked gas and biomass oil. Coke is introduced into the gasification reactor, and a mixture of 50 parts by weight of steam and oxygen (500°C) based on 100 parts by weight of coke is introduced into the gasification reactor, where the moles of steam and oxygen are 6:1, the gasification reaction is car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com