A biological filler for sewage treatment

A biological filler and sewage treatment technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, anaerobic digestion treatment, etc. The effect of cycle life and improvement of material exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

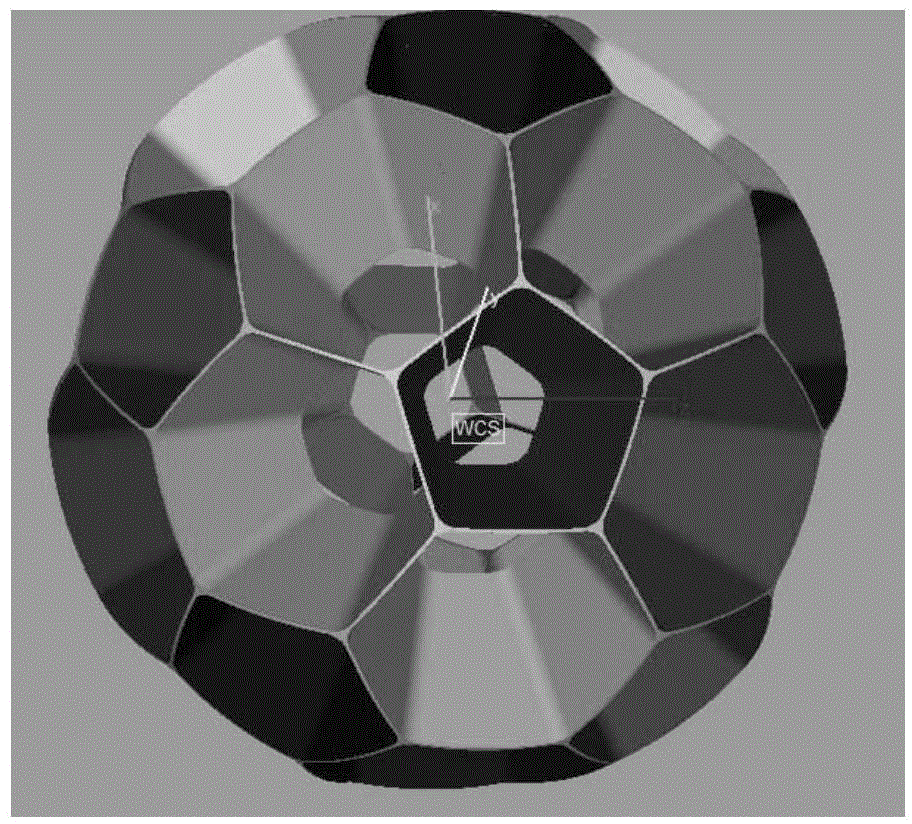

[0049] The honeycomb-like spherical biofiller structure of this embodiment is as follows figure 1 As shown, this kind of honeycomb-shaped spherical biological filler is mapped to the spherical surface with 32-hedron as the basic topology to obtain a three-dimensional hollow honeycomb-like spherical structure composed of 5-sided and 6-sided honeycombs. During mapping, except for the edges of the 32-hedron, the rest of the parts are Hollow structure.

[0050] In this embodiment, the biofiller is prepared by selective laser sintering (SLS), and the raw material used in selective laser sintering (SLS) is PS with a particle size of 500 mesh.

[0051] The shape and performance parameters of the obtained honeycomb-like spherical biofiller in this embodiment are as shown in Table 1:

[0052] Table 1 Example 1 Type Honeycomb Spherical Biofiller Shape and Performance Parameters

[0053] diameter

100mm

thickness

0.5mm

Depth:

25mm (1 / 2 radius)

...

Embodiment 2

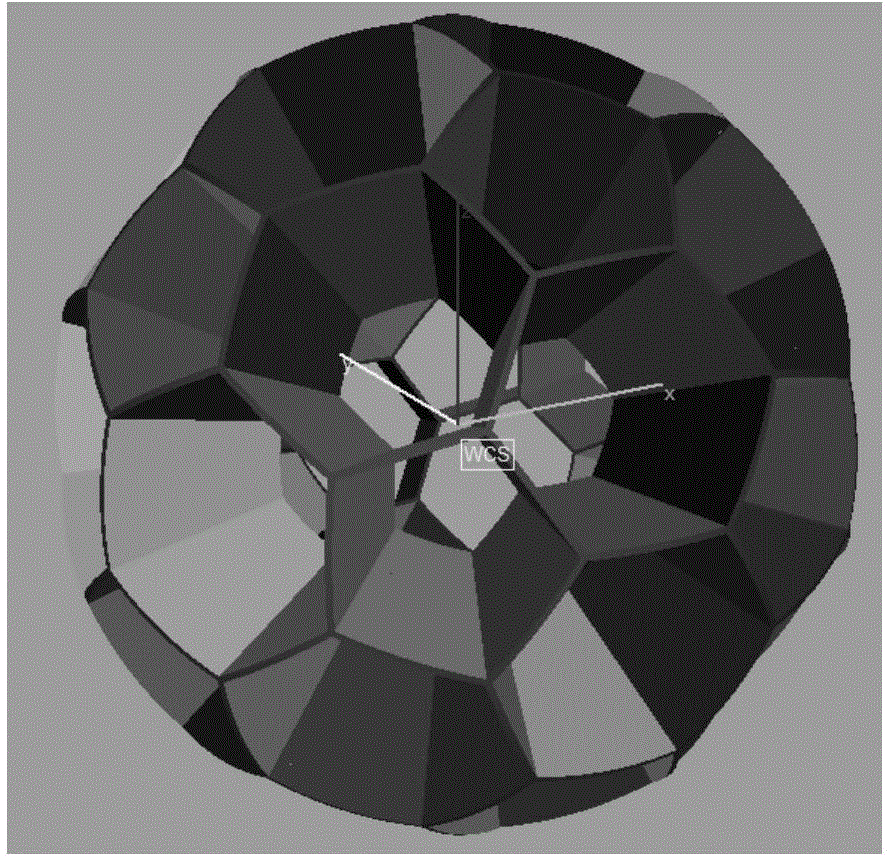

[0057] The honeycomb-like spherical biofiller structure of this embodiment is as follows figure 2 As shown, the difference between this embodiment and Example 1 is that the diameter of the honeycomb-like spherical biological filler in this embodiment is 50mm; the shape and performance parameters of the honeycomb-like spherical biological filler obtained in this embodiment are shown in Table 2:

[0058] Table 2 Example 1 Class honeycomb spherical biofiller shape and performance parameters

[0059] diameter

50mm

thickness

0.5mm

Depth:

12.5mm (1 / 2 radius)

[0060] surface area

17218mm^2

volume

3153mm^3

specific surface area

5461

quality

3.5g

95.2%

[0061] As shown in Table 2, the depth of the honeycomb is 1 / 2 of the radius of the ball, the thickness of the side wall of the honeycomb is 0.5mm, and the mass is 3.5g; the specific surface area is 5461, and the por...

Embodiment 3

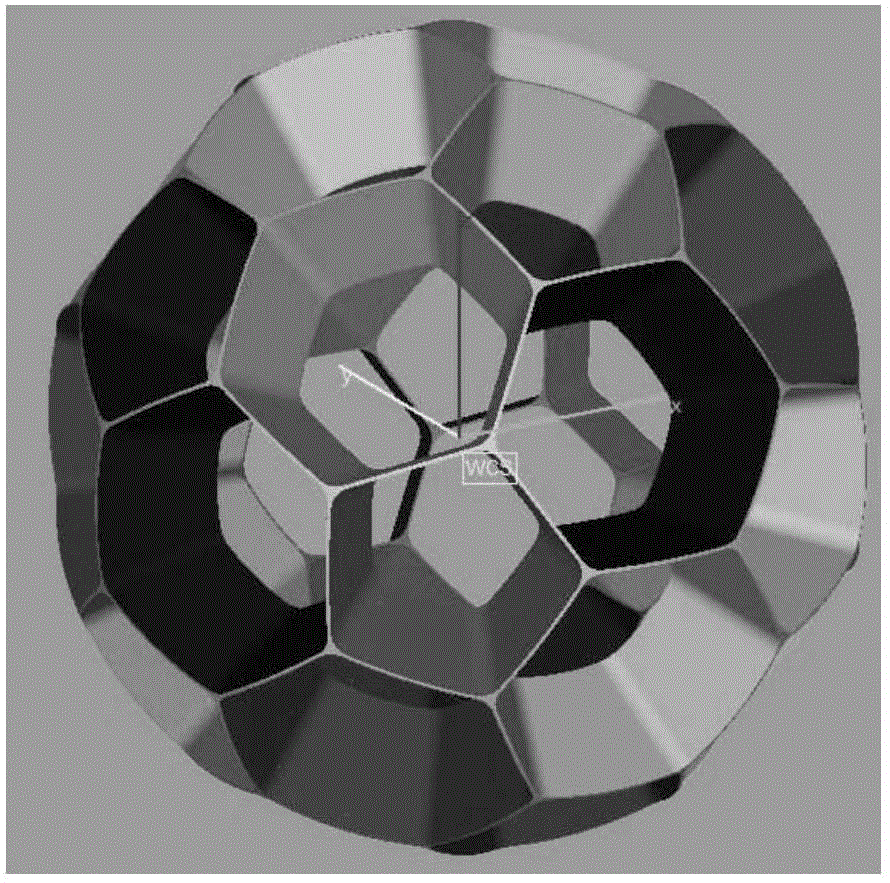

[0064] The honeycomb-like spherical biofiller structure of this embodiment is as follows image 3 As shown, the difference between this embodiment and Embodiment 1 is that the honeycomb-like spherical biological filler in this embodiment has a honeycomb depth of 1 / 3 of the radius of the ball.

[0065] After testing, the quality of the prepared honeycomb-like spherical biological filler in this embodiment is 12g; its surface area is 50530mm 2 , with a volume of 11723mm 3 , the specific surface area is 4310, and the porosity is 97.8%.

[0066] After testing, the surface roughness of the honeycomb-like spherical biofiller prepared in this example is 70um, the tensile strength is 35MPa, the bending strength is 25MPa, and the impact strength (notch strength) is 3.2KJ / m^2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com