Machining work clamp for planetary plate ball socket of vehicle air conditioning compressor

A vehicle-used air conditioner and tooling fixture technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve problems such as increased product defect rate, unstable tooling and fixture processing, and affecting normal production of the factory. Enhance stability and prevent radial loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The accompanying drawings disclose, without limitation, the structural schematic diagrams of the preferred embodiments involved in the present invention; the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

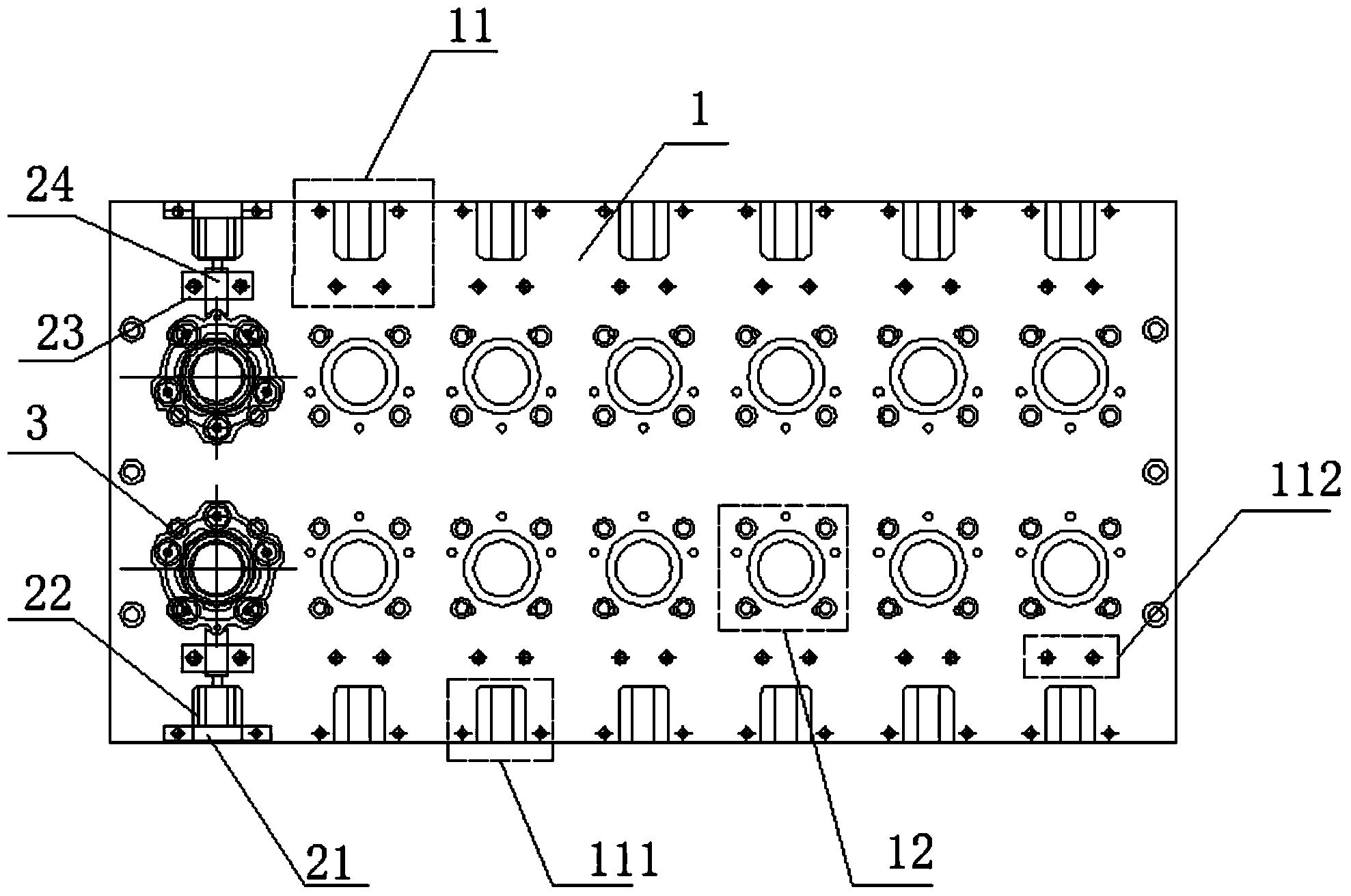

[0022] Such as figure 1 As shown, the planetary disc ball socket processing fixture of the vehicle air-conditioning compressor according to the present invention is used for clamping and positioning the workpiece (planetary disc), including a base plate and a clamping assembly, wherein:

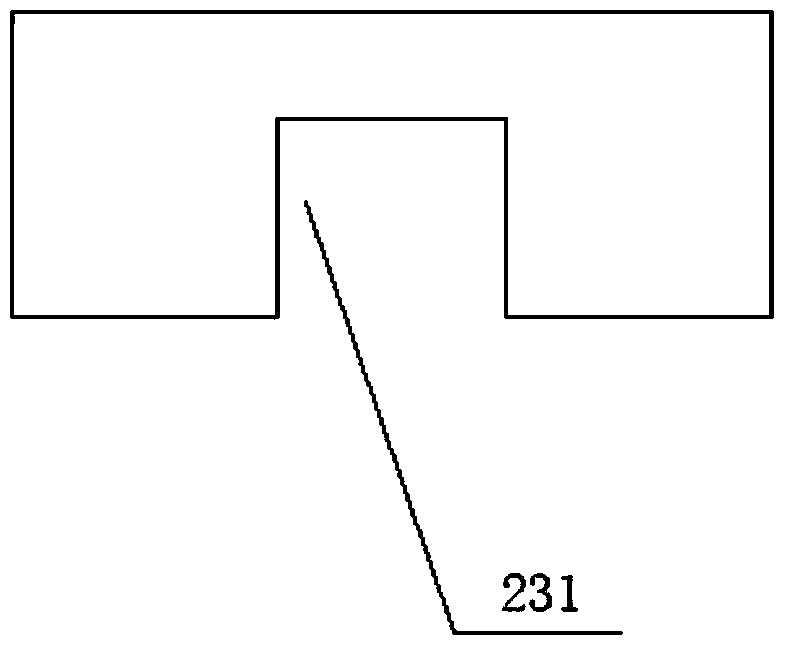

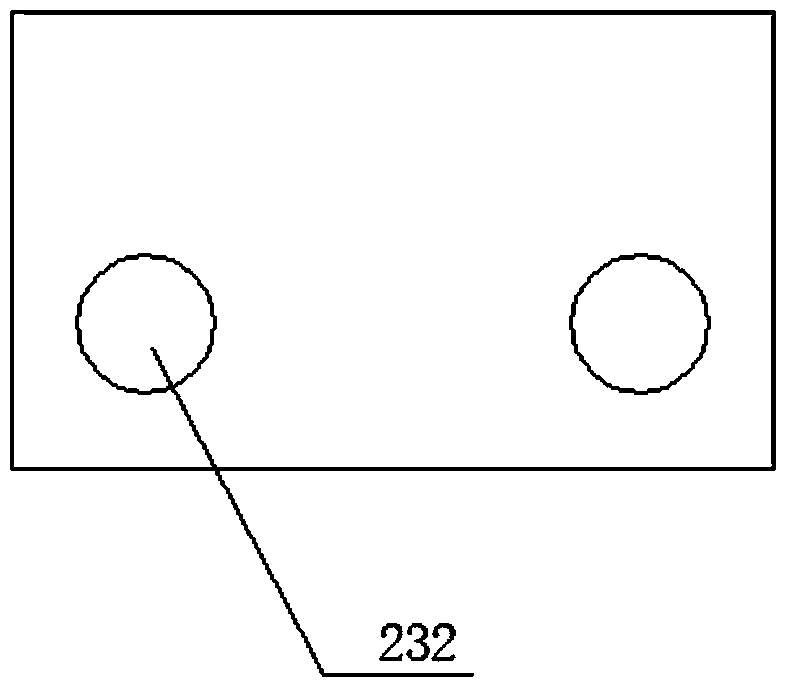

[0023] The bottom plate includes several repeating areas, and each repeating area includes a clamping assembly installation area and a workpiece installation area; the clamping assembly installation area and the workpiece installation area are located on the coaxial line; and the clamping The component installation area includes a clamp installation part and a guide installation part; the clamp installatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com