Re-manufacturing machining process of surface of inner hole of hydraulic cylinder scrap guide sleeve

A processing technology and hydraulic cylinder technology, which is applied in the field of remanufacturing processing technology for the surface of the inner hole of the scrapped guide sleeve of the hydraulic cylinder, can solve the problems of low size performance, high reprocessing cost, waste of resources, etc., to reduce production costs and save resources , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

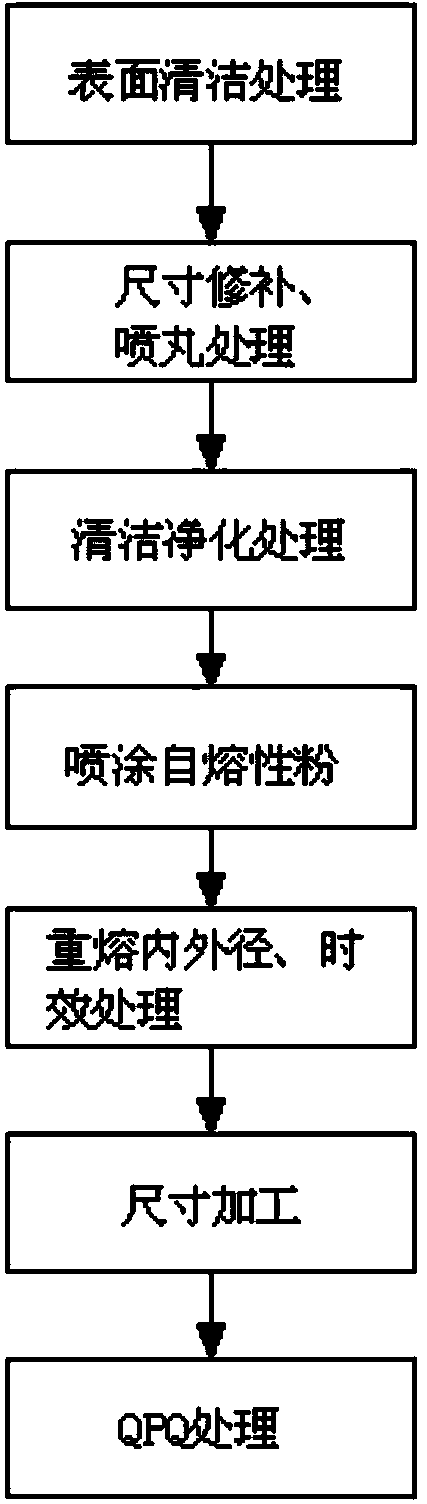

[0030] Such as figure 1 As shown, the main steps of the processing technology of the present invention are surface cleaning treatment, size repair and shot blasting treatment, cleaning and purification treatment, spraying self-fluxing powder, remelting outer circle diameter, inner hole diameter and aging treatment, size processing, QPQ deal with.

[0031] The steps briefly described above can be specifically the following steps:

[0032] Step 1) Clean the hydraulic cylinder guide sleeve in the early stage of processing. In this step, firstly wash the hydraulic cylinder guide sleeve with water to remove the dust on the hydraulic cylinder guide sleeve, and then clean the outer surface and inner hole wall of the hydra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com