Method and apparatus for texturing of multifilament filaments

A multi-fiber and filament technology, applied in textiles and papermaking, etc., can solve the problems of fast dirt, unreliable optical system, etc., and achieve high quality and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

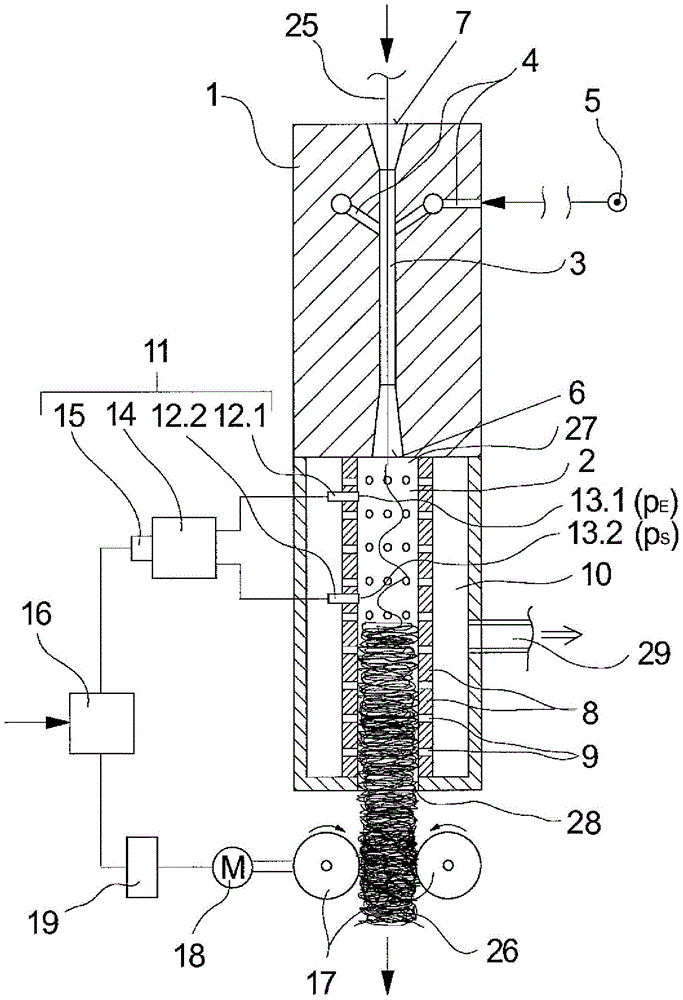

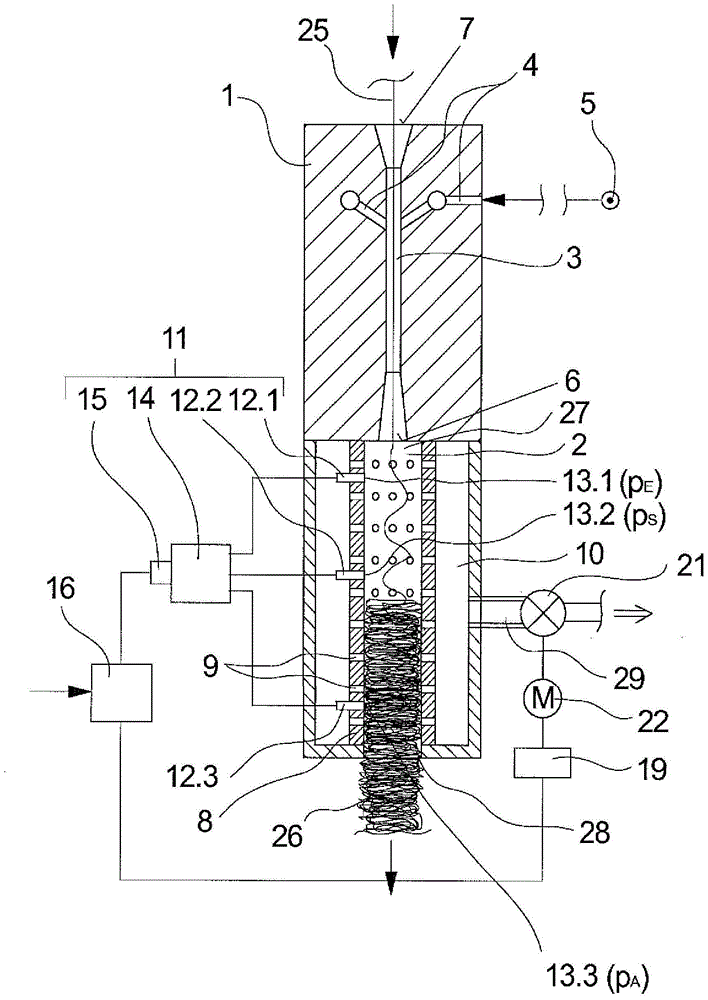

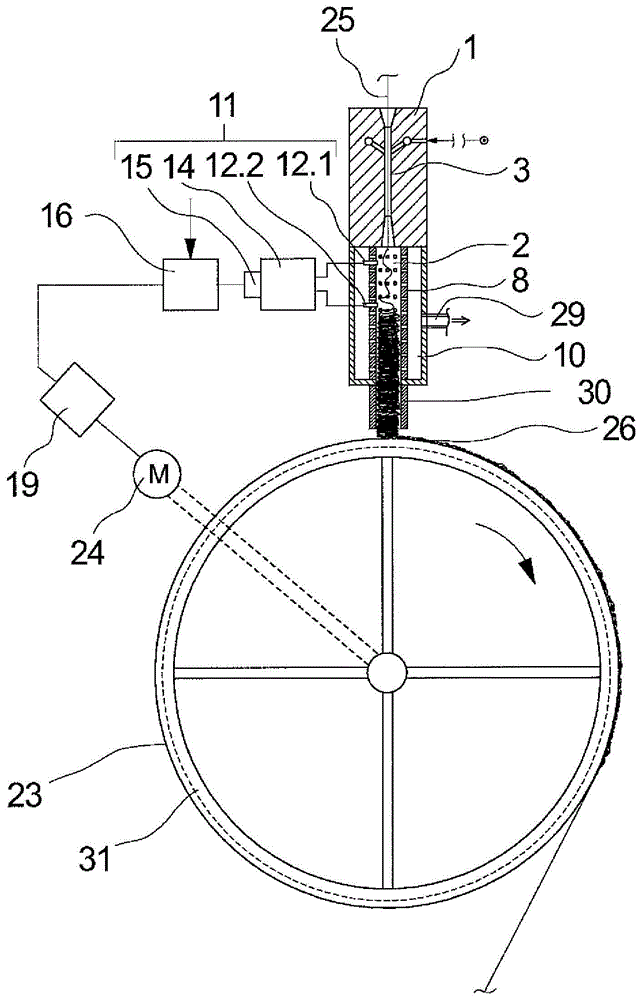

[0030] exist figure 1 A first embodiment of the device according to the invention is schematically shown in a cross-sectional view in FIG. The device has a delivery nozzle 1 comprising a vertically extending filament channel 3 . The filament channel 3 extends from a filament inlet 7 on the top side of the delivery nozzle 1 to a filament outlet 6 on the bottom side of the delivery nozzle 1 . A plurality of compressed air channels 4 open into the thread channel in the upper region of the delivery nozzle 1 and connect the thread channel to a compressed air source 5 . Further components, not shown here, are provided between delivery nozzle 1 and compressed air source 5 for conducting and processing the compressed air. It is common, for example, to heat the compressed air before entering the filament channel 3 .

[0031] Directly adjoining the underside of the delivery nozzle 1 is a stuffer box 2 , which is delimited by a gas-permeable box wall 8 and held within the suction chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com