Vertical wrapping mould for multiple pairs of parallel symmetrical axis cables

A parallel, symmetrical, longitudinal molding technology, applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve problems such as large mechanical stress, signal transmission loss, wire structure deformation, etc., to remove mechanical stress, improve attenuation and delay , The effect of stabilizing high-frequency transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

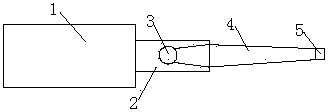

[0017] Combine below figure 1 Specific description embodiment:

[0018] Multiple pairs of parallel symmetrical axis cable longitudinal covering molds, characterized in that the multiple pairs of parallel symmetrical axis cable longitudinal covering molds include a fixing seat 1, and the ends of the fixing seats 1 are connected with connectors 2, and the connecting parts A threading hole 3 is provided on the piece 2, and one end of the connecting piece 2 is communicated with a die mouth 4, and the threading hole 3 communicates with the die mouth 4, and the length of the die mouth 4 is 5-8cm. The front end of the die nozzle 4 is a die opening 5 . The die mouth is formed by curling a plate into a tube shape, and the die mouth gradually shrinks from the end far away from the die mouth to the die mouth.

[0019] The parallel symmetrical axis cable enters the die mouth through the wire inlet hole, and then forms cables in a circular (section) on multiple pairs of symmetrical axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com