multifunctional stove

A multi-functional stove technology, applied in household stoves/stoves, stoves/stoves with hot water devices, heating methods, etc., can solve the problems of high use cost, low heat utilization rate, waste of resources, etc., and achieve simple structure , Ease of use, resource-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

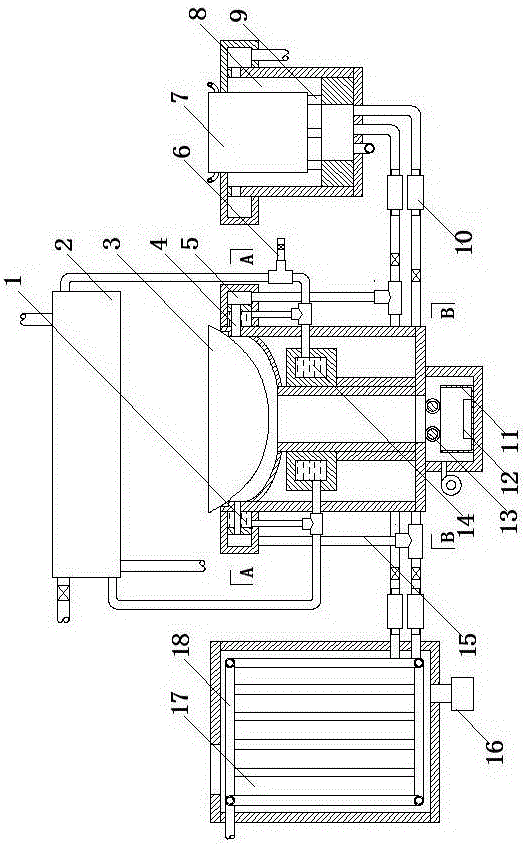

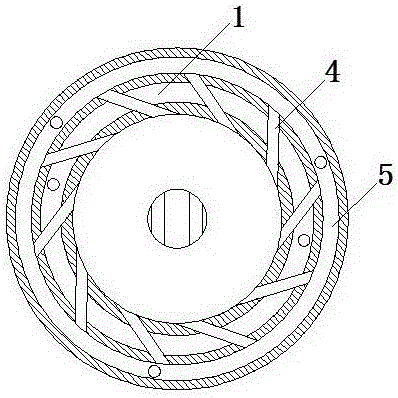

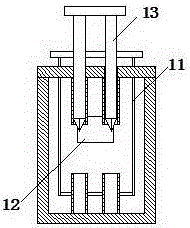

[0035] Embodiment one: if figure 1 , figure 2 , image 3 , Figure 4 As shown, the multifunctional stove of the present invention includes a furnace surrounded by high-temperature-resistant materials, a blower, a waste heat recovery device and a waste heat utilization device. The bottom of the hearth is provided with a movable furnace bridge 13, and the top is provided with an opening for placing a frying pan 3, and the frying pan 3 contacts, connects and seals with the top of the hearth to form a heating zone. A movable furnace bridge 13 is provided at the bottom of the furnace. A dust accumulating chamber is arranged below the movable furnace bridge 13 . Also be provided with ash drawer 11 in the ash accumulating cavity. Ash drawer 11 inner bottom corresponding furnace bottom position is provided with protrusion 12, and the distance between this protrusion 12 top and movable furnace bridge 13 bottoms is less than the height of lotus root briquettes. The air outlet of ...

Embodiment 2

[0042] Embodiment two: if Figure 5 As shown, the hot blast pipe 15 is connected with the furnace of two holding furnaces and the radiating pipe 19 of the circulating water tank by a tee, a control valve, and a screw sleeve 10 simultaneously. This combination is more suitable for use in the kitchen of rice noodle shops. One of the heat preservation furnaces is used for heat preservation of non-chili soup, the other heat preservation furnace is used for heat preservation of spicy soup, the hot water in the circulating water tank is used for washing dishes and vegetables, and the cooking pot 3 is used for cooking or blanching powder, which is more convenient to use.

Embodiment 3

[0043] Embodiment three: as Image 6 Shown, when adopting fuel oil or gas as fuel, be provided with fuel oil or gas burner head 20. The furnace bottom is open. The combustion burner 20 is placed at the bottom of the heating zone of the furnace, so that the fuel combustion flame of the combustion burner 20 enters the heating zone.

[0044] The holding furnace, radiating pipe 19, heater, and disinfection cabinet of the present invention can be arbitrarily configured according to needs and the number of holding furnace, heat dissipation pipe 19, heater, and disinfection cabinet can be arbitrarily configured according to needs, and are more suitable for fast food restaurants, soup powder Shop, home and other kitchen use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com