Segmented gas-sealed heat treatment process for hot-dip galvanized strip and its alloying furnace

An alloying furnace and hot-dip galvanizing technology, applied in heat treatment furnaces, hot-dip galvanizing processes, heat treatment equipment, etc., can solve the problem that the heat cannot ensure the process temperature of the middle heat preservation section, the process cannot meet the high temperature and then low temperature, and the quality cannot be stable Control and other issues to achieve the effect of reducing heat dissipation, protecting subsequent equipment, and stabilizing temperature and pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

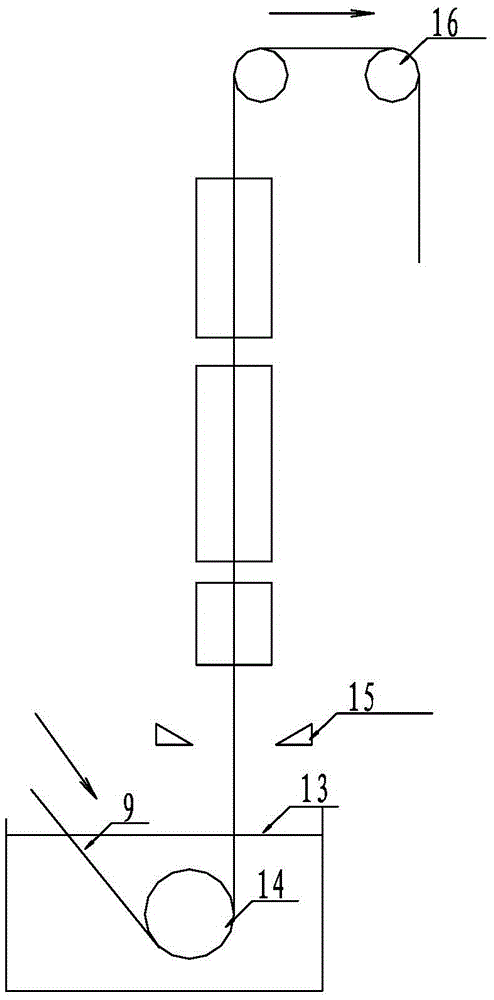

[0026] Such as figure 1 As shown, the hot-dip galvanized steel strip subsection gas-sealed alloying furnace of the present invention is installed between the zinc pot 13 and the furnace top roll 16 on the galvanizing production line, and the strip steel 9 passes from the sinking roll 14 in the zinc pot 13 Lead out, through the air knife 15 to control the thickness of the galvanized layer, enter the alloying furnace for heat treatment, and finally output around the furnace top roller 16.

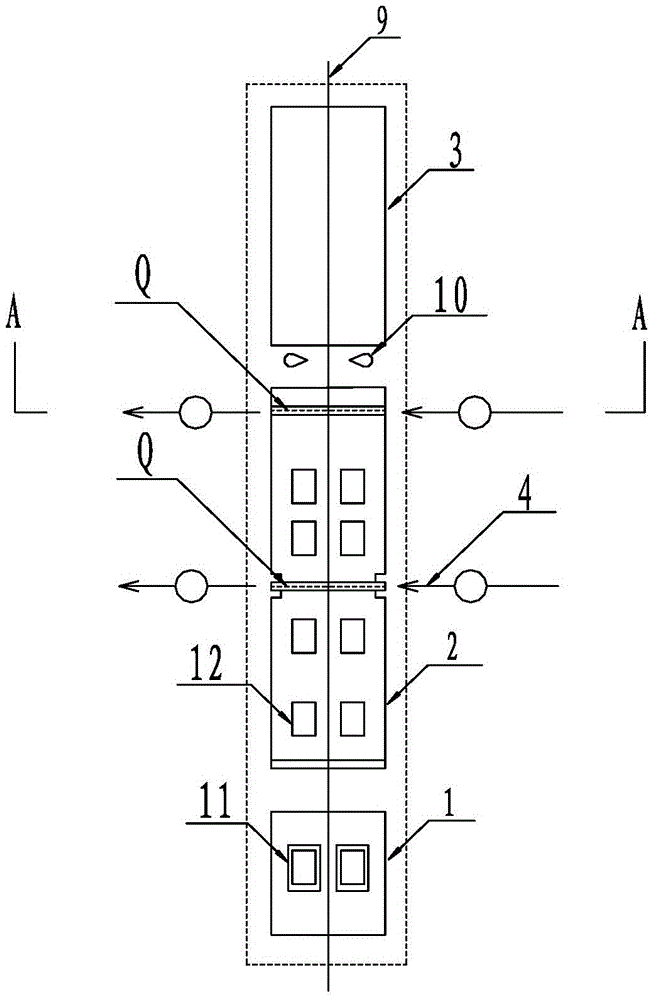

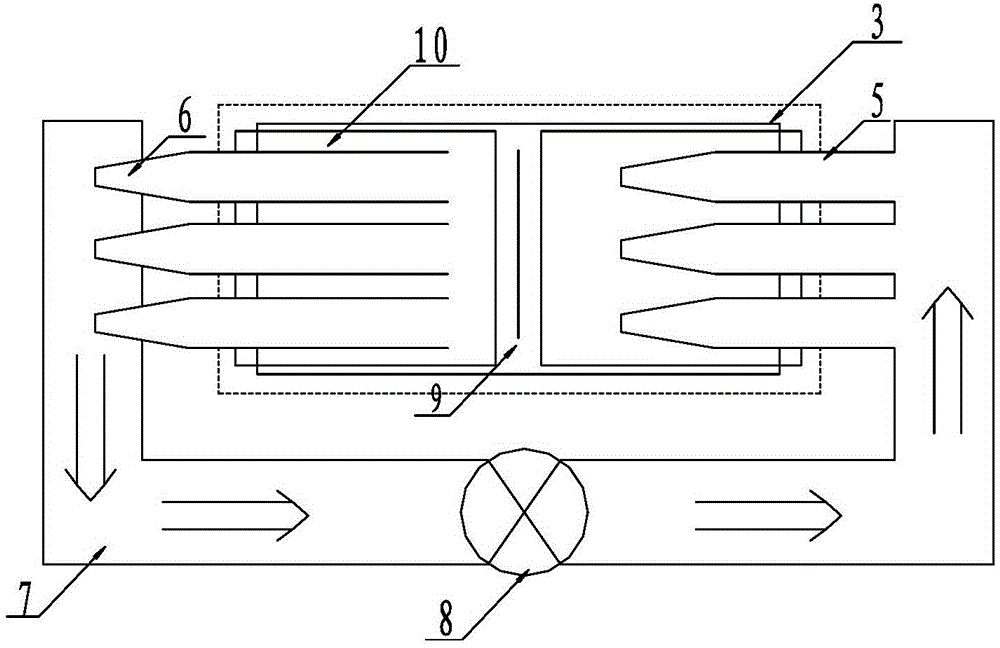

[0027] Such as Figure 2~3 As shown, the alloying furnace is mainly composed of a bottom heating section 1, a middle heat preservation section 2 and an upper cooling section 3. Wherein, the bottom heating section 1 is provided with an induction heater 11, which is used to quickly heat the strip steel 9 to the design temperature; the middle heat pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com