A kind of negative ion foaming water-based ink and preparation method thereof

A technology of water-based ink and negative ions, which can be applied to inks, household utensils, applications, etc., can solve the problems of health hazards for residents, affect the negative ion release function of wallpaper, and unfavorable full contact of tourmaline crystals, etc., and achieve good three-dimensional decoration effects and coating Plump, delicate ink effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

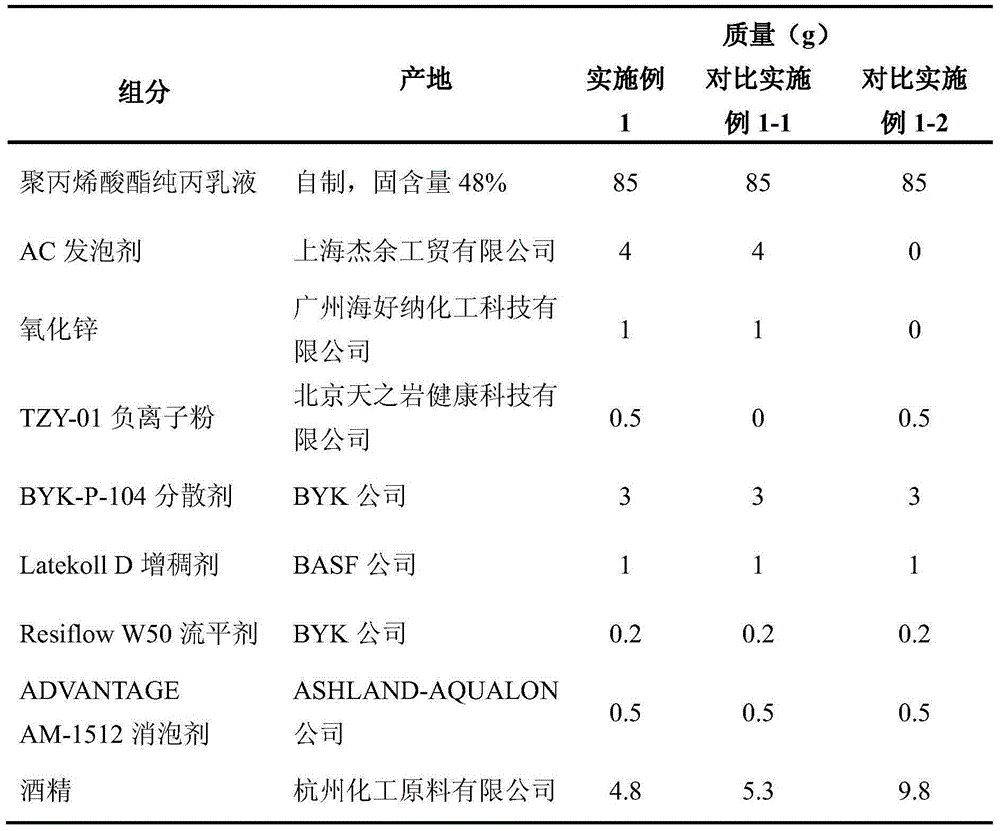

Embodiment 1

[0038] According to the formula amount (0.5wt% negative ion powder, 4wt% foaming agent addition) of embodiment 1 in table 2, polyacrylate pure acrylic emulsion, BYK-P-104 dispersant, LatekollD thickener, ResiflowW50 leveling ADVANTAGEAM-1512 defoamer and ADVANTAGEAM-1512 defoamer were sequentially added into the dispersion sand mill (Jiangyin Shuangfeng Chemical Machinery Co., Ltd.), started stirring at a speed of 500 rpm, and kept the stirring speed constant, then added AC foaming agent, To the mixture of zinc oxide and TZY-01 negative ion powder, add alcohol at the end and keep stirring for 40 minutes to obtain negative ion foaming water-based ink products. See the foaming effect of ink on non-woven paper wallpaper figure 1 , product performance indicators are shown in Table 3.

Embodiment 2

[0047] Table 4. Embodiment 2 water-based ink composition raw material formula (0.5wt% negative ion powder, 5wt% foaming agent addition)

[0048]

[0049] Note: The self-made polyacrylate pure acrylic emulsion has applied for an invention patent, the application number is 2013105793039, and the publication number is CN103601837A.

[0050] According to the formulation amount in Table 4, polyacrylate pure acrylic emulsion, BYK-P-104 dispersant, LatekollD thickener, ResiflowW50 leveling agent and ADVANTAGEAM-1512 defoamer are added to the dispersion sand mill (Jiangyin City) successively In Shuangfeng Chemical Machinery Co., Ltd.), start stirring at a speed of 500 rpm, keep the stirring speed constant, then add the mixture of AC foaming agent, zinc oxide and TZY-01 negative ion powder, finally add alcohol, keep stirring for 60 Minutes later, the negative ion foaming water-based ink product is obtained. Product performance indicators are shown in Table 8.

Embodiment 3

[0052] Table 5. Embodiment 3 water-based ink composition raw material formula (0.5wt% negative ion powder, 8wt% foaming agent addition)

[0053]

[0054] Note: The self-made polyacrylate pure acrylic emulsion has applied for an invention patent, the application number is 2013105793039, and the publication number is CN103601837A.

[0055] According to the formulation amount in Table 5, polyacrylate pure acrylic emulsion, BYK-P-104 dispersant, LatekollD thickener, ResiflowW50 leveling agent and ADVANTAGEAM-1512 defoamer are added to the dispersion sand mill (Jiangyin City) successively In Shuangfeng Chemical Machinery Co., Ltd.), start stirring at a speed of 300 rpm, keep the stirring speed constant, then add the mixture of AC foaming agent, zinc oxide and TZY-01 negative ion powder, finally add alcohol, keep stirring for 60 Minutes later, the negative ion foaming water-based ink product is obtained. Product performance indicators are shown in Table 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com