Method for producing compound fertilizer containing nitrate nitrogen potassium sulphate

A technology of potassium sulfate type and production method, applied in fertilization equipment, fertilizer mixture, application, etc., can solve the problems of inconvenient increase of nitrate nitrogen, prone to explosion, and limitation of addition amount, and achieve new sales points, easy to dissolve , good moisture control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

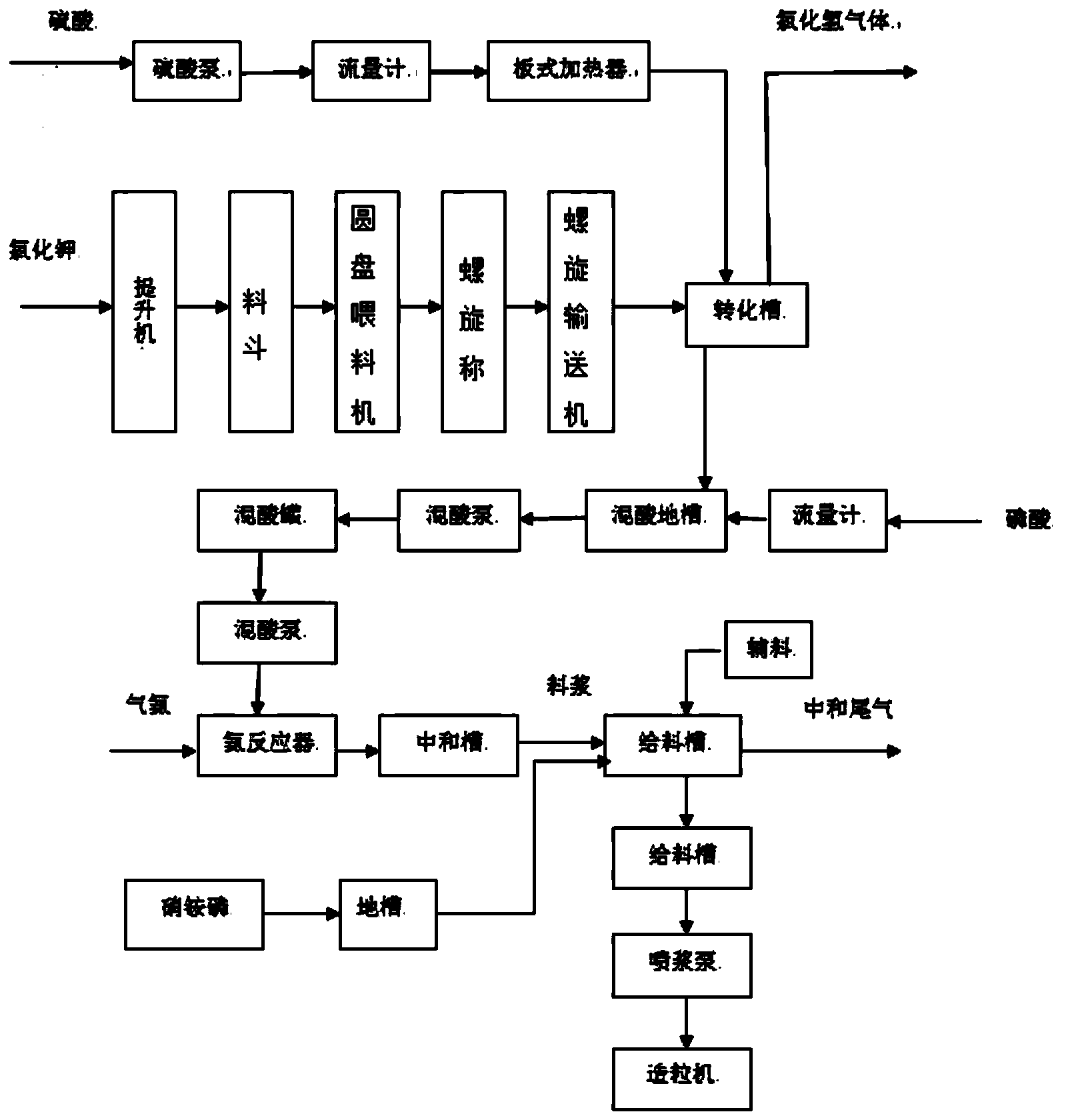

[0026] Embodiment 1: a kind of production method that contains nitrate nitrogen potassium sulfate type compound fertilizer, as figure 1 As shown, it is achieved through the following steps:

[0027] (1) Preparation of ammonium nitrate slurry: Dissolve nitrate with condensed water at 60°C or compound fertilizer tail gas washing liquid. When the temperature of the slurry cannot be reached, use low-pressure steam to heat it. The low-pressure steam is controlled at 0.1MPa. The slurry temperature is controlled at 50-70°C, and the specific gravity of the ammonium nitrate slurry is 1.35g / ml;

[0028] (2) Preparation of mixed acid: the sulfuric acid solution with a mass fraction of 98% from the circulation tank of the sulfuric acid workshop is controlled at a temperature between 80 and 90°C. The sulfuric acid pump measures the sulfuric acid solution through a flow meter and sends it to a plate heater, which is heated by steam. Enter the conversion tank after request;

[0029] Potass...

Embodiment 2

[0042] The difference between this embodiment and tool embodiment 1 is:

[0043] In the step (1), the low-pressure steam is controlled at 0.3Mpa; the ammonium nitrate-phosphorus slurry specific gravity is 1.45g / ml;

[0044] In step (2), the specific gravity of phosphoric acid is 1.23g / ml, and the material ratio 1T of potassium chloride, sulfuric acid, phosphoric acid: 0.82m 3 : 3.5m 3 ;

[0045] The mass ratio of the neutralized slurry to the ammonium nitrate slurry in step (4) is 1:0.16.

[0046] Gained nitrogen (N) content is 13.18% in the potassium sulfate type compound fertilizer containing nitrate nitrogen, wherein, ammoniacal nitrogen 11.19%, nitrate nitrogen 1.99%, nitrate nitrogen content reaches 15.10% in the nitrogen element, phosphorus content (with effective P 2 o 5 Calculated) is 17.52%, potassium content (in K 2 O) is 13.52%.

Embodiment 3

[0048] The difference between this embodiment and embodiment 1 is:

[0049] In the step (1), the low-pressure steam is controlled at 0.6Mpa; the specific gravity of the ammonium nitrate slurry is 1.40g / ml;

[0050] In step (2), the specific gravity of phosphoric acid is 1.25g / ml, and the material ratio 1T of potassium chloride, sulfuric acid, phosphoric acid: 0.85m 3 : 3.6m 3 ;

[0051] In step (4), the mass ratio of the neutralized slurry to the ammonium nitrate slurry is 1:0.13.

[0052] Gained nitrogen (N) content is 13.10% in the potassium sulfate type compound fertilizer containing nitrate nitrogen, wherein, ammoniacal nitrogen 11.52%, nitrate nitrogen 1.58%, nitrate nitrogen content reaches 12.06% in the nitrogen element, phosphorus content (with effective P 2 o 5 Calculated) is 17.96%, potassium content (in K 2 O) 13.61%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com