Fine coal microwave medium intensified magnetic separation cleaning system and fine coal microwave medium intensified magnetic separation cleaning process

A technology of microwave medium and enhanced magnetism, applied in the fields of magnetic separation, chemical instruments and methods, solid separation, etc., can solve the problems of high construction cost and operating cost, complex structure and composition, weak pyrite magnetism, etc., and achieve stable operation, The effect of increasing the difference in specific magnetic susceptibility and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

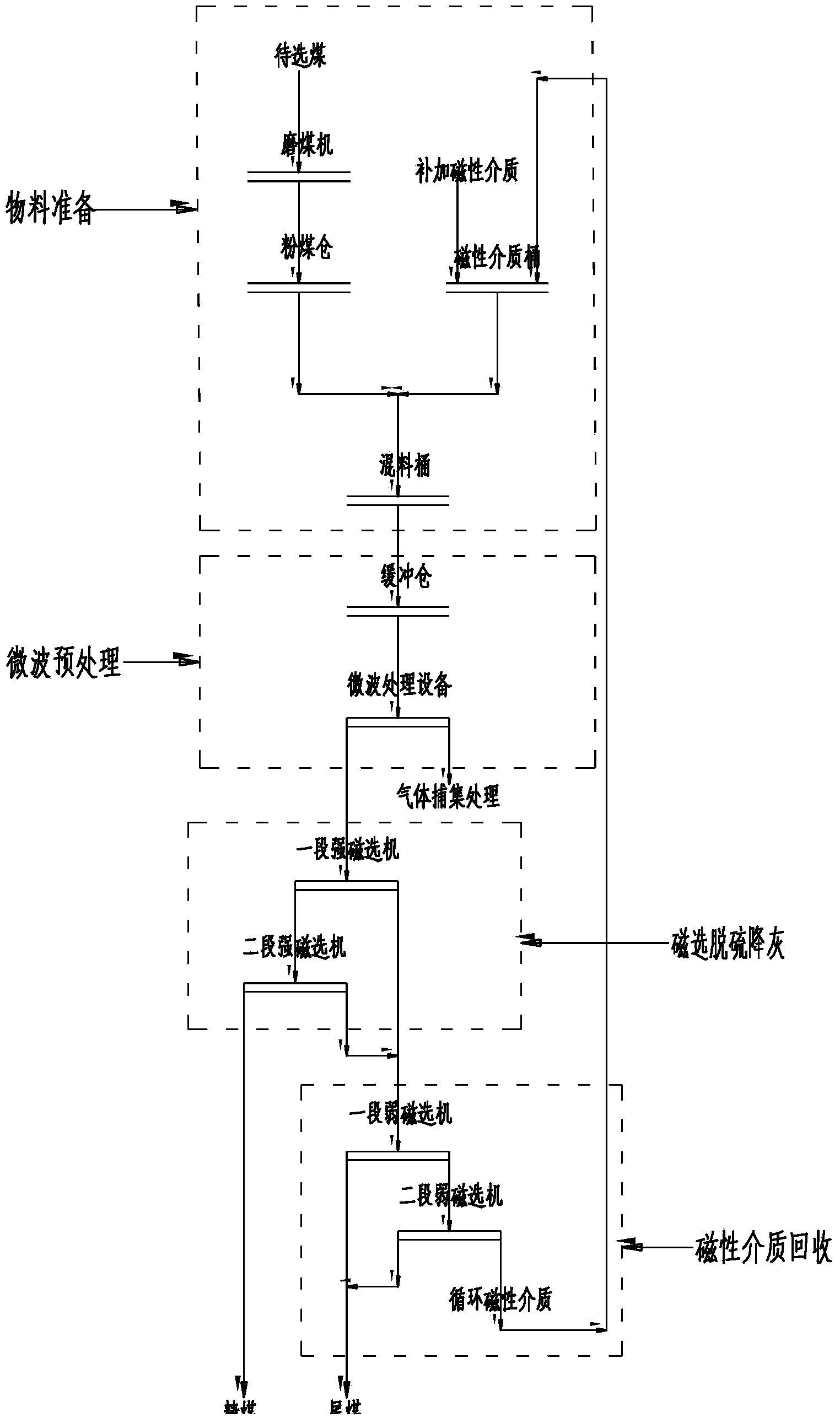

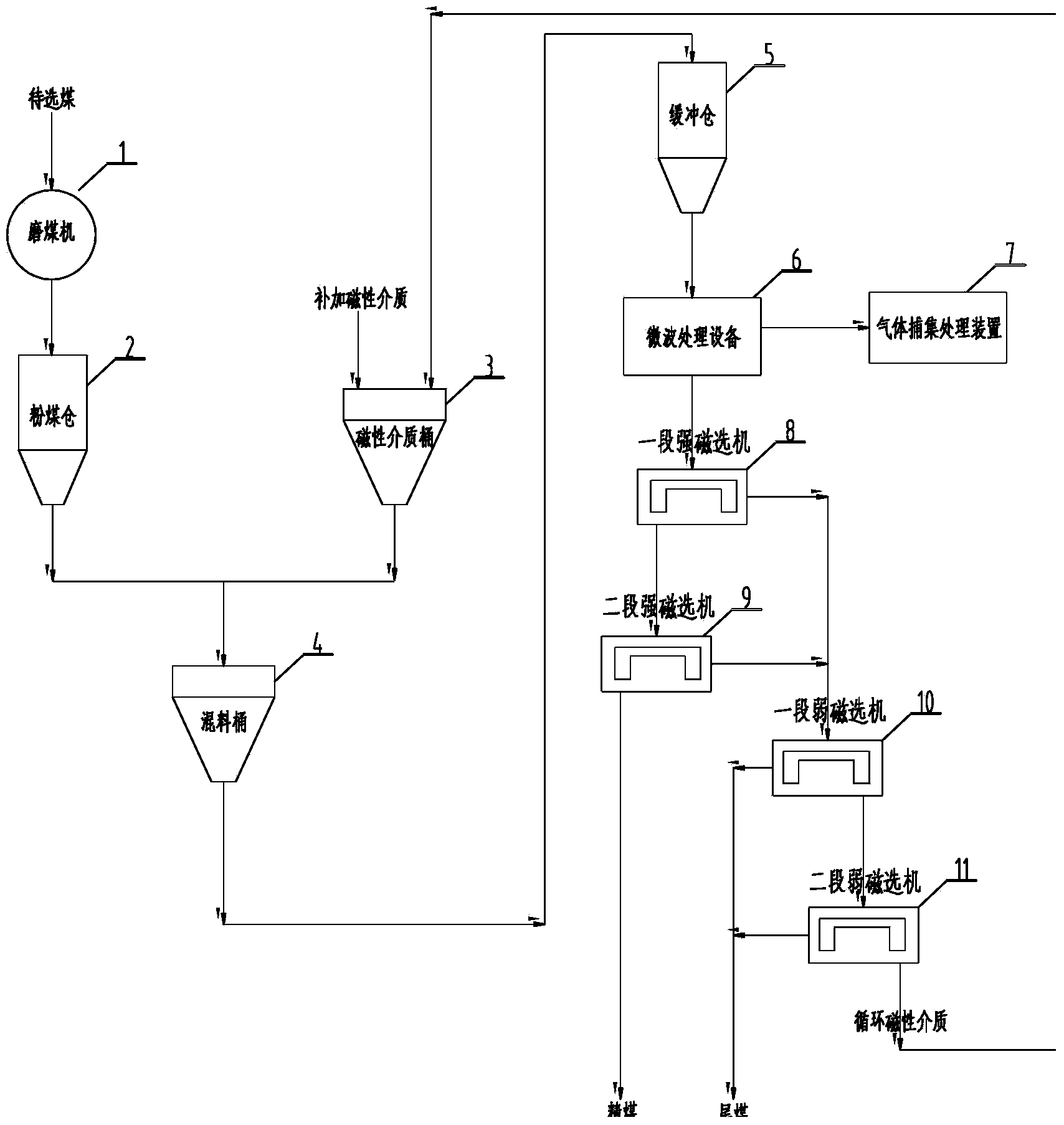

[0018] exist figure 1 and figure 2 Among them, the fine-grained coal microwave medium enhanced magnetic separation cleaning system and process of the present invention include four parts: material preparation part A, microwave pretreatment part B, magnetic separation desulfurization and ash reduction part C, and magnetic medium recovery part D. Among them, material preparation part A includes coal mill 1, pulverized coal bin 2, magnetic medium barrel 3, and mixing barrel 4; microwave pretreatment part B includes buffer bin 5 and microwave processing equipment 6; magnetic separation desulfurization and ash reduction part C, It includes a first-stage strong magnetic separator 8 and a second-stage strong magnetic separator 9; the magnetic medium recovery part D includes a first-stage weak magnetic separator 10 and a second-stage weak magnetic separator 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com