A kind of preparation method of agricultural biomass carbon-based magnetic adsorption material

A magnetic adsorption material and biomass carbon technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal compounds, etc., can solve the problems of reduced adsorption capacity of activated carbon, cumbersome preparation process, cumbersome process, etc., and achieve good magnetic properties and adsorption performance, broad application prospects, and the effect of a wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

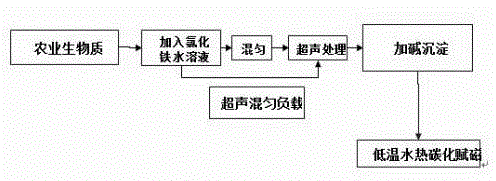

Method used

Image

Examples

Embodiment 1

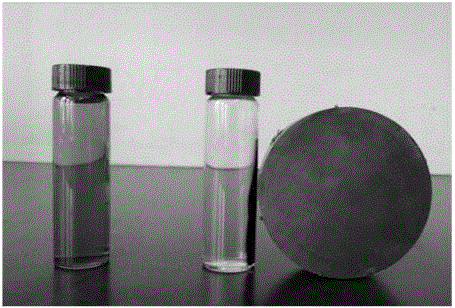

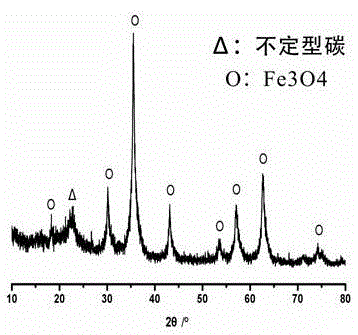

[0028] Example 1 Preparation of carbon-based magnetic adsorption material with corn cob as biomass

[0029] Collect the corncobs in the experimental field of our research group, dry them at 90°C after cleaning and crush them, pass through a 100-mesh sieve and collect the sieved corncob powder, take 4g of corncob powder and add it to 100mL of 0.1mol / L FeCl 3 In the solution, the 400rmp rotating speed is stirred evenly, and after 500W ultrasonic wave 1h, the FeCl powder dispersed with corn cob powder is obtained. 3 solution. FeCl dispersed in corncob flour after sonication 3Add 4g of NaOH to the solution, continue to stir vigorously at 500rmp, then transfer to a hydrothermal reaction kettle and seal the hydrothermal reaction kettle, react at 220°C for 6h, filter and wash repeatedly with deionized water after the reaction to obtain a magnetic carbon-based adsorption material 2.5g.

Embodiment 2

[0030] Example 2 Preparation of carbon-based magnetic adsorption material with rice husk as biomass

[0031] Collect the rice husks harvested and processed in the experimental field of our research group, dry them at 100°C after washing and crush them, pass through a 100-mesh sieve and collect the sieved rice husk powder, take 6g of rice husk powder and add it to 100mL0.5mol / LFeCl 3 In the solution, the 400rmp rotation speed was stirred evenly, and then the FeCl powder dispersed with rice husk powder was obtained by ultrasonication at 500W for 1.5h. 3 solution. FeCl dispersed rice husk powder after ultrasonic 3 Add 5g of NaOH to the solution, continue to stir vigorously at 500rmp, then transfer to a hydrothermal reaction kettle and seal the hydrothermal reaction kettle, react at 200°C for 10h, filter after the reaction and wash repeatedly with deionized water to obtain a magnetic carbon-based adsorption material 3.2g.

Embodiment 3

[0032] Example 3 Preparation of Carbon-based Magnetic Adsorbent Material Using Wheat Straw as Biomass

[0033] Collect the wheat straw in the experimental field of our research group, wash it, dry it at 105°C and crush it, pass it through a 100-mesh sieve and collect the sieved wheat straw powder, take 5g of the wheat straw powder and add it to 100mL of 0.6mol / L FeCl 3 In the solution, the 400rmp rotation speed was stirred evenly, and then the FeCl powder dispersed with wheat straw powder was obtained by ultrasonication at 500W for 2h. 3 Dispersion solution. FeCl dispersed wheat straw powder after sonication 3 Add 4g of NaOH to the solution, continue to stir vigorously at 500rmp, then transfer to a hydrothermal reaction kettle and seal the hydrothermal reaction kettle, react at 240°C for 8h, filter and wash repeatedly with deionized water after the reaction to obtain a magnetic carbon-based adsorption material 2.3 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com