A high-gravity cross-flow high-pressure full-phase reactor for preparing nano-alumina

A nano-alumina and supergravity technology, applied in the direction of alumina/aluminum hydroxide, pressure vessels used in chemical processes, etc., can solve the problems of complex production process of nano-alumina, environmental pollution, high cost, and reduced product performance. Achieve ultra-refined equipment technology, ensure product friendliness, and facilitate production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited to the following embodiments.

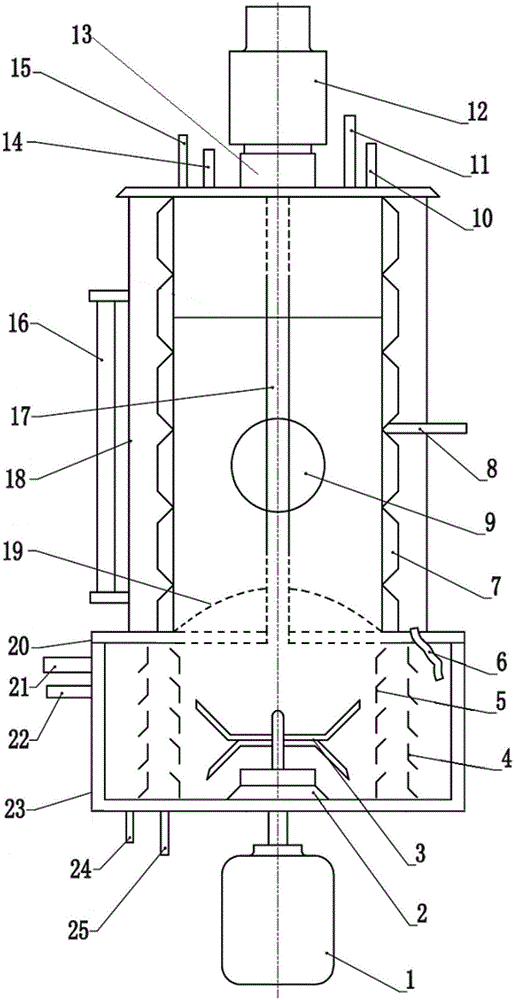

[0024] The overall structure of the high-gravity cross-flow high-pressure full-phase reactor provided by the invention is as follows: figure 1 As shown, the whole is made of stainless steel. The device includes a kettle body and an inner tank, the inner tank is located inside the kettle body, and an observation window 9 is arranged on the side wall in the middle of the kettle body for observing the reaction status in the kettle body. An upper jacket 18 is installed on the top of the kettle body, and a lower jacket 23 is installed on the bottom of the kettle body. The bottom of the kettle body is provided with a cleaning port 25 connected to the lower chamber.

[0025] The middle part of described still body is provided with partition frame 20, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com