Method of Reducing Torque Fluctuation of Spliced Servo Motor by Reluctance Compensation

A servo motor, reluctance torque technology, used in the control of generators, motor generator control, control of electromechanical brakes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

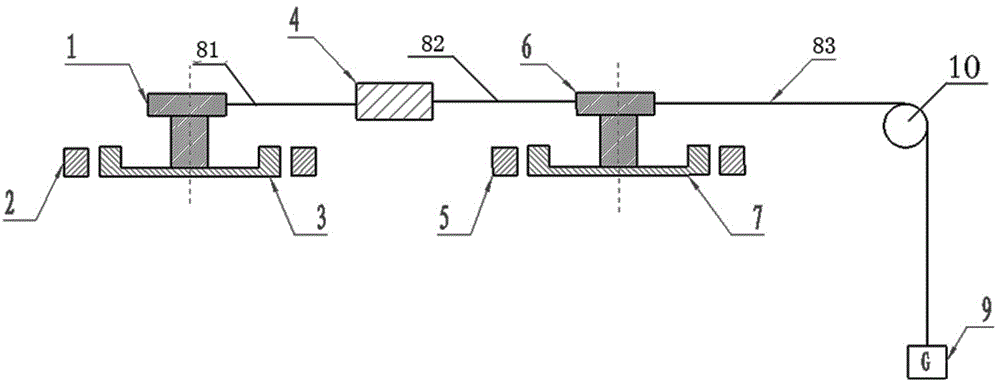

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

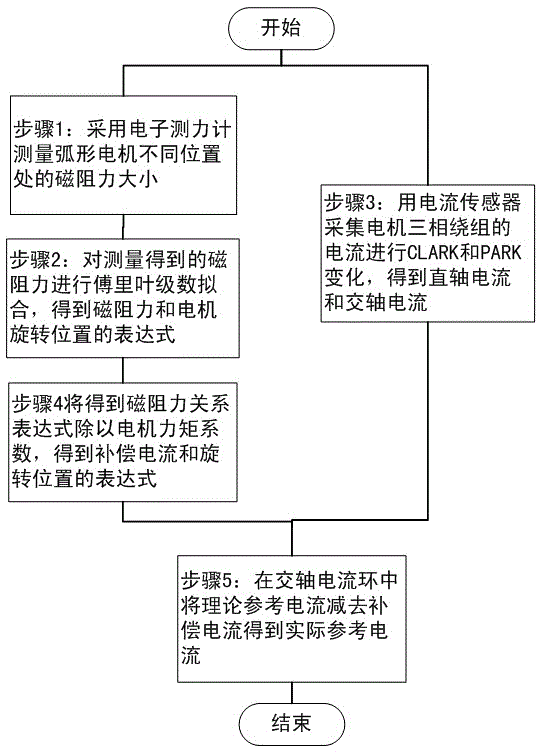

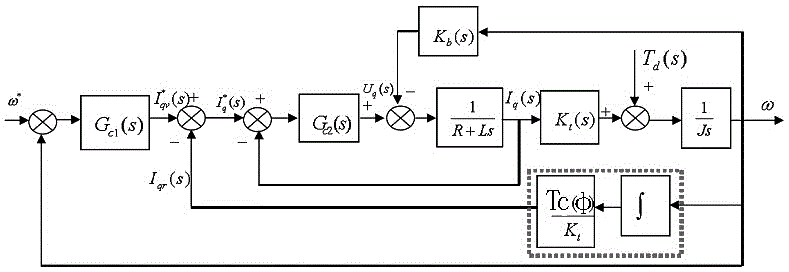

[0026] The actual output torque of the motor mainly includes two parts, electromagnetic torque and disturbance torque. The disturbance torque here specifically refers to the reluctance torque of the motor itself. Assuming that the motor winding does not contain high-order harmonics and the air-gap flux density of the motor is a sine wave, the electromagnetic torque output by the motor is a constant value. The reluctance torque of the motor is a function of periodic fluctuations related to its own structural form. When using vector control, there is a linear relationship between the electromagnetic torque of the motor and the quadrature axis current. Since the reluctance torque is a periodic function of the rotational po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com