Wiring tool and wiring method using the tool

A tooling and wiring technology, applied in the field of wiring tooling, can solve problems such as poor batch consistency, low production efficiency, and complex wiring, and achieve the effects of improving efficiency, reducing deviation, and shortening process length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

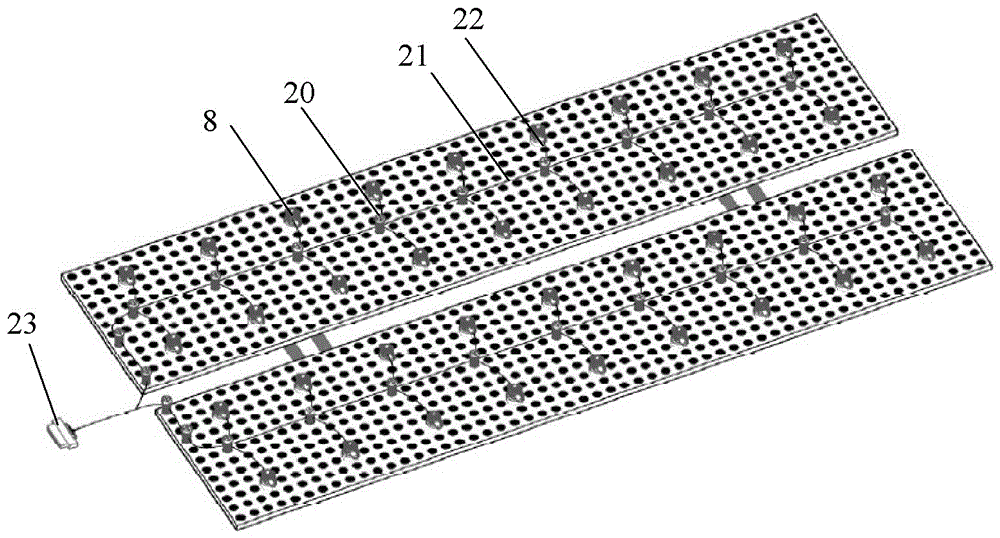

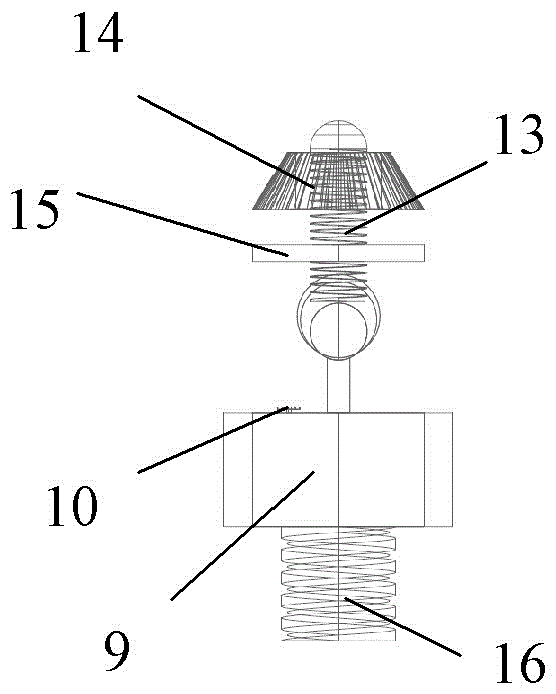

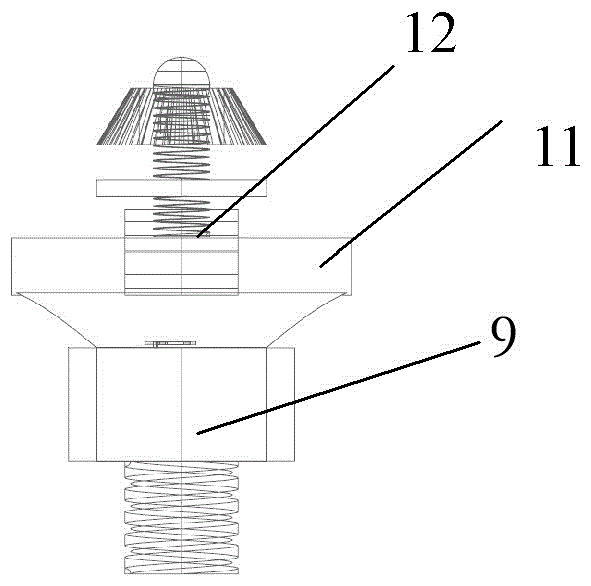

[0028] The embodiment of wiring tooling among the present invention: as Figure 1 to Figure 8 As shown, the wiring tool is a tool specially used to equip the battery cells in the battery pack with voltage and temperature acquisition lines. It is mainly composed of a wiring board 1, a terminal post 8 and a binding screw. The mounting holes 2 are distributed in a square matrix. The terminal 8 is a special bolt that can fasten a variety of crimped ends at the end of the collection line. The terminal 8 has a terminal bolt, a radial adjustment mechanism, a rotation mechanism and Fix the bolt 16, wherein the connecting bolt is screwed with a fastening chassis 15 and a fastening nut 14 above it, and the fastening nut 14 and the fastening chassis 15 are used together to form a fastening tube type, needle type, The wiring structure of the end of the collection line such as O-shaped and U-shaped; the radial adjustment mechanism consists of a slider 12 fixed on the bottom of the wiring b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com