Rapid liquid mist characteristic measuring method based on digital image treatment technique

A liquid mist characteristic and digital image technology, which is applied in the field of non-contact liquid mist characteristic measurement, can solve the problems of different measurement of liquid atomization field characteristic parameters, insufficient measurement parameters, narrow measurement range, etc., and achieve detailed liquid mist characteristic parameters. , reduce measurement costs, and achieve fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

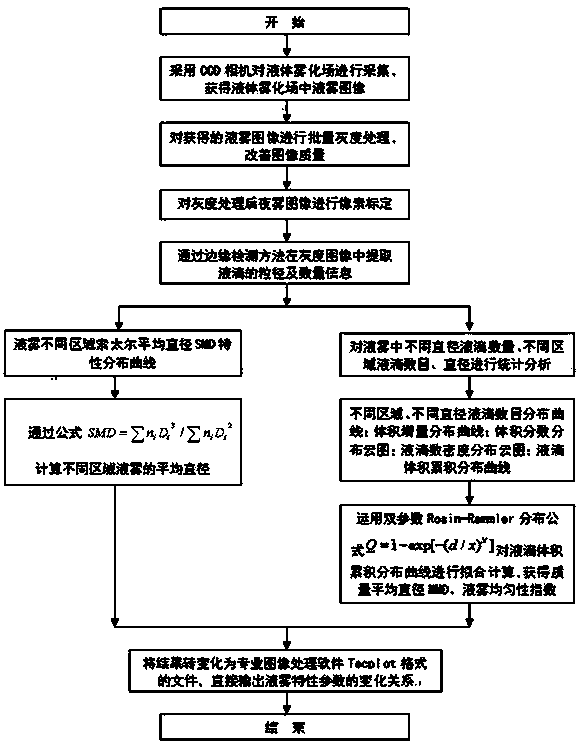

[0031] A kind of rapid measurement method of liquid mist characteristic based on digital image processing technology of the present invention, such as figure 1 shown, including the following steps:

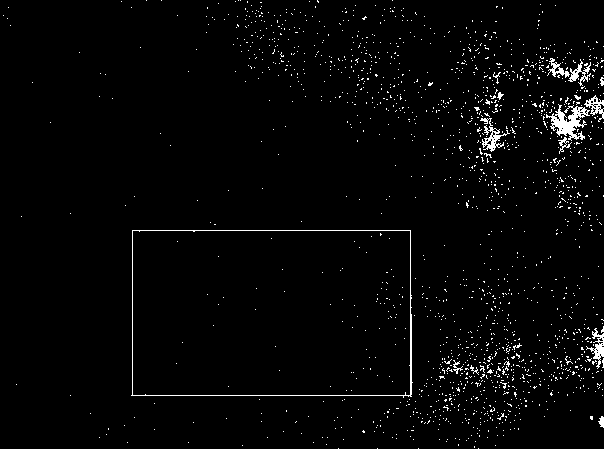

[0032] Step 1: Collect images of the liquid mist with a CCD camera to obtain liquid mist images such as figure 2 shown.

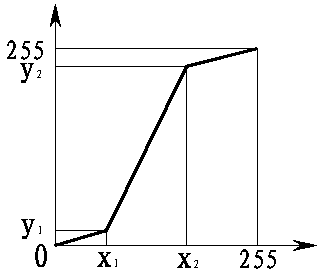

[0033] Step 2, using piecewise linear grayscale transform (GST) processing technology to perform grayscale processing on the image obtained in step 1, such as image 3 As shown, the gray scale of the image is divided into 3 segments, and the gray scale linear transformation is performed on each segment, and the pixel points with gray scale values between 0 and x1 are compressed into gray scale values from 0 to y1, and the gray scale values The compressed gray value of pixels between x2 and 255 is y2 to 255. And stretch the gray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com