Marine compact type SCR catalysis silencer

A catalytic muffler, a compact technology, applied in mufflers, machines/engines, engine components, etc., can solve problems such as noise, achieve the effect of improving uniformity, prolonging operating life, and saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

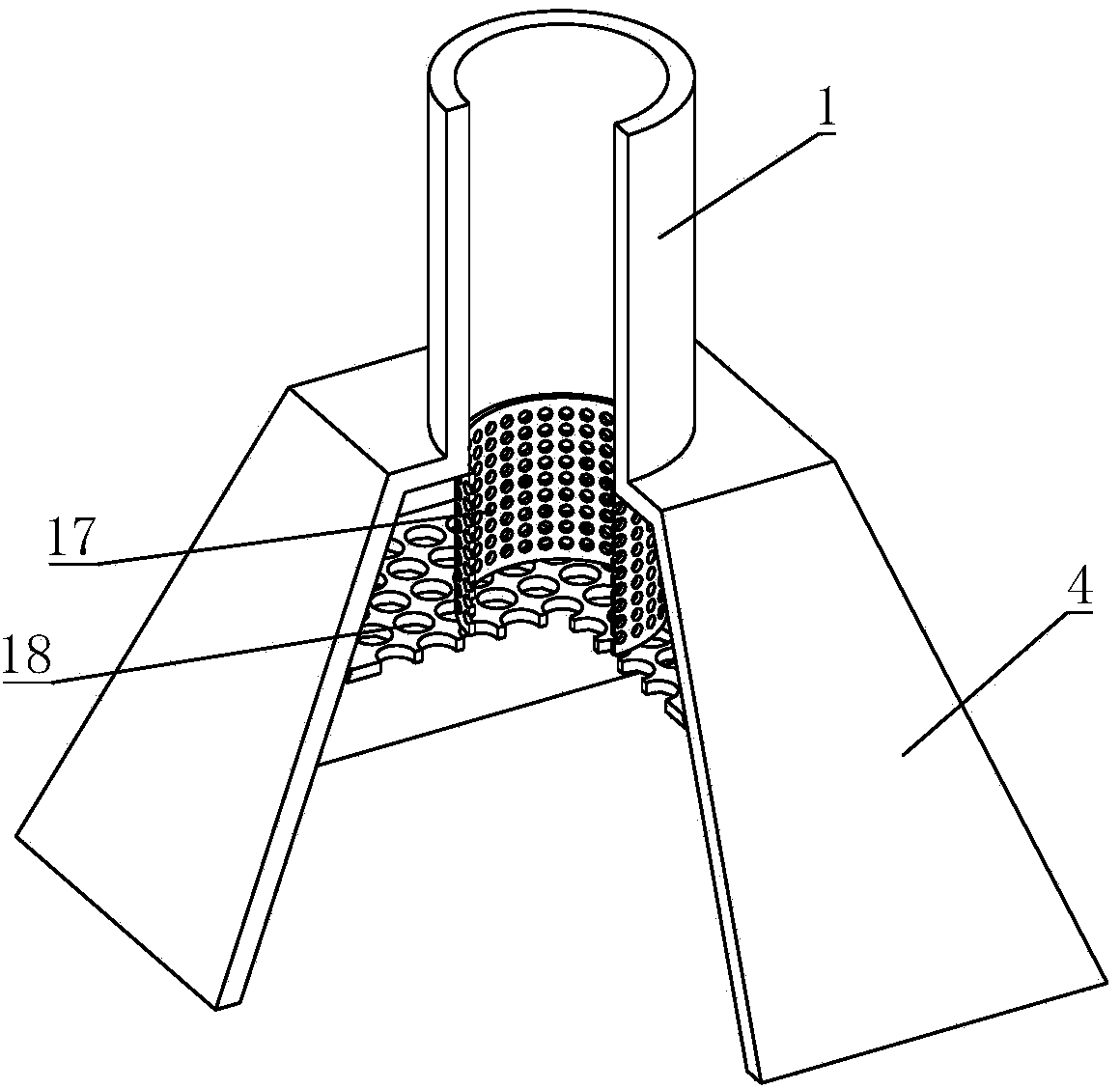

[0036] Example 4, such as Figure 6 As shown, the muffler device 6 includes an inner insertion pipe 17 and a built-in 18 plate located in the diffuser pipe 4; the inlet of the inner insertion pipe 17 is connected with the outlet of the inlet pipe 1, and the inner insertion pipe 17 There is a gap between the outlet and the built-in plate 18, and the built-in plate 18 is perpendicular to the axis of the inner insertion tube 17; hole; the outlet of the inner insertion tube 17 is provided with a sealing plate 16 for sealing the outlet of the inner insertion tube 17; In this way, although the reflection of the sound wave is reduced, the exhaust gas must experience two sudden expansions and contractions, which makes the effect of low-frequency noise better than that in Embodiment 3.

Embodiment 5

[0037] Embodiment 5, such as Figure 7 As shown, the difference between this embodiment and Embodiment 6 is that a plurality of through holes are evenly distributed on the sealing plate 16 . In this way, the total cross-sectional area of the exhaust gas is increased, and the exhaust efficiency is improved. Preferably, the diameter of the upper through hole of the sealing plate 16 is equal to the diameter of the through hole on the tube wall of the inner insertion tube 17 .

[0038] In the above five embodiments of the muffler device, preferably, the cross-sections of the diffuser tube 4 and the shrink tube 5 are both rectangular.

[0039] In the above five embodiments of the muffler device, preferably, the length of the inner insertion pipe 6 is 1 / 4˜1 / 2 of the length of the diffuser pipe 4 .

[0040] In the above five embodiments of the muffler device, preferably, the diameter of the through hole on the inner insertion pipe 6 is 1 / 20-1 / 10 of the inner diameter of the exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com