A method for processing iron and steel smelting dust and a processing system therefor

A technology of iron and steel smelting and processing method, which is applied in the field of comprehensive utilization of resources, can solve the problems of polluting the environment, endangering human health, and high surface free energy, and achieves the effects of simple process method, guaranteed safety and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

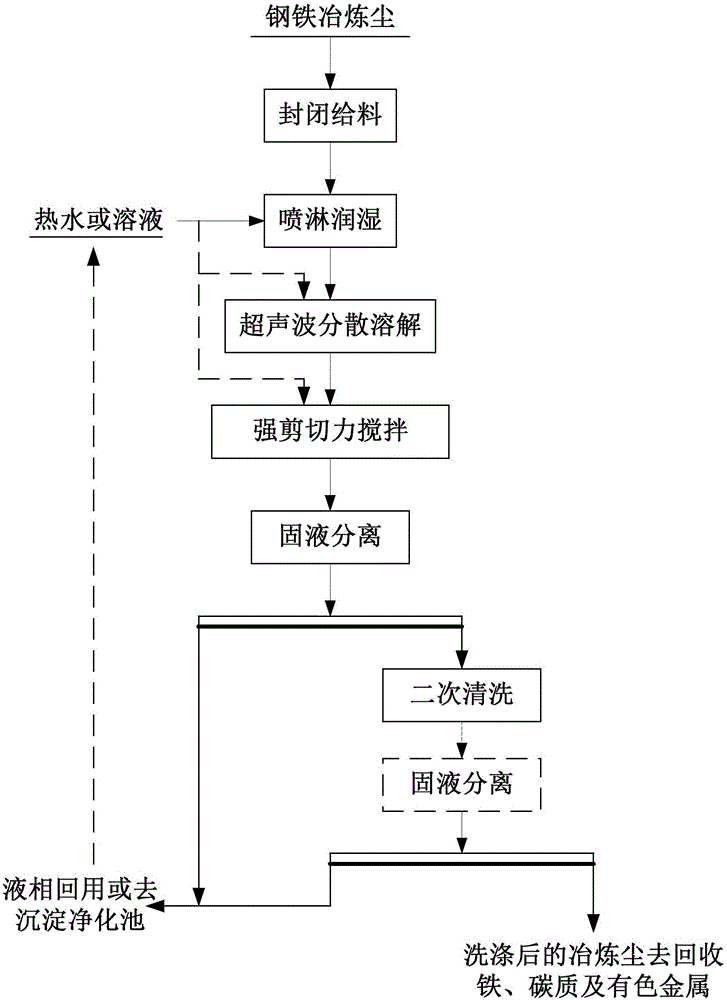

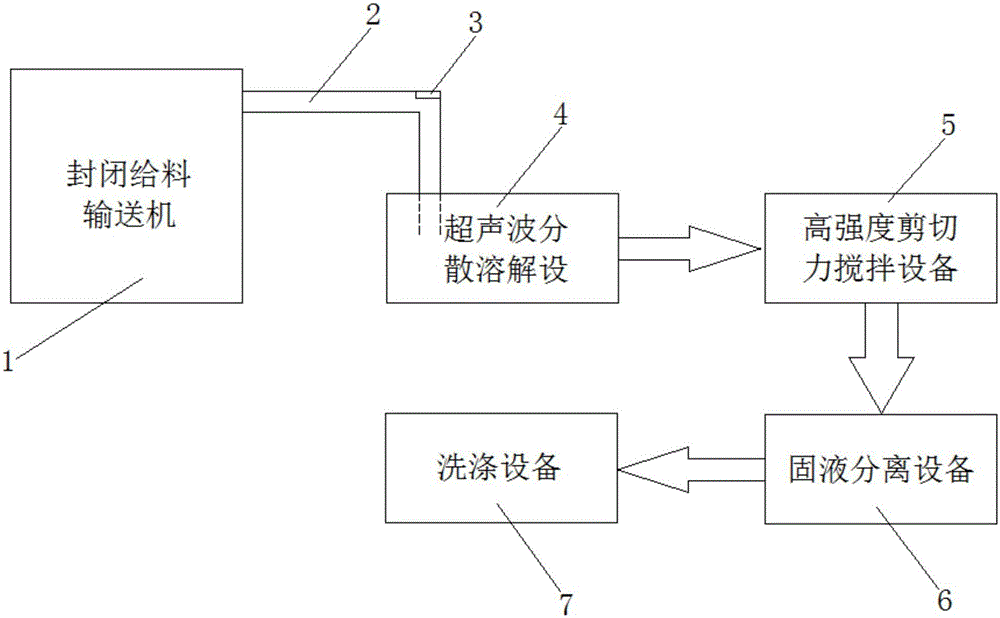

Method used

Image

Examples

specific experiment example 1

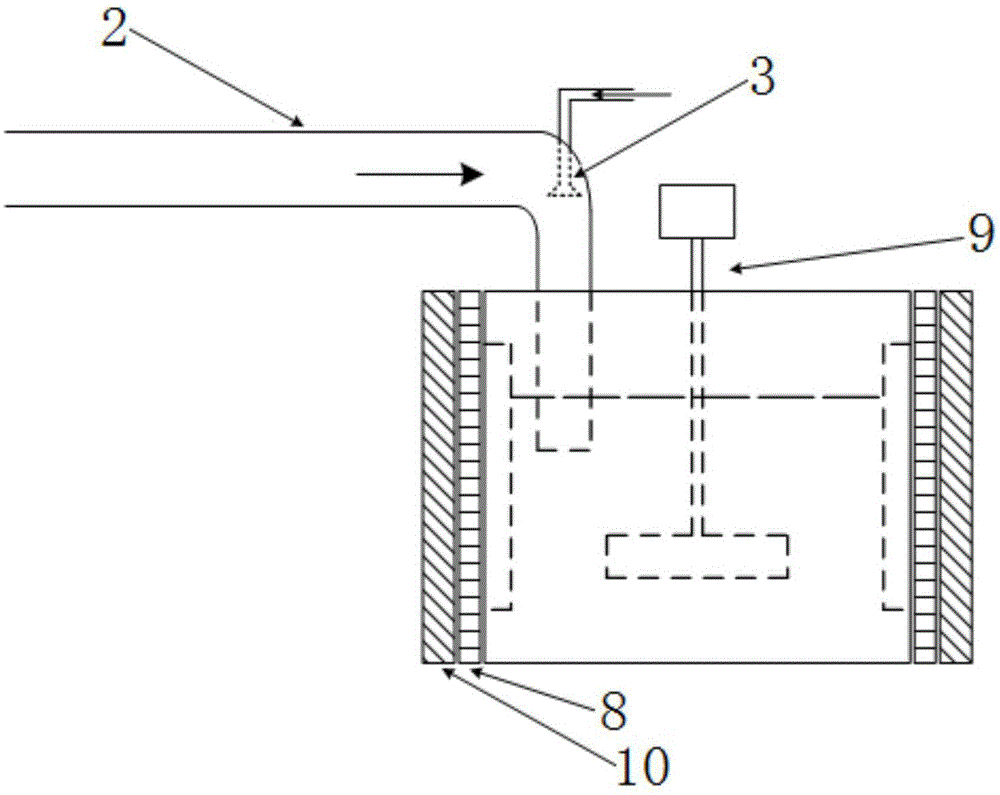

[0059] The machine head ash from a steel plant is fed through a closed belt to a high-strength shear mixing equipment with ultrasonic dispersion and dissolution functions. Spray equipment is used at the place where it enters the mixing equipment, and it is pre-wetted with 55°C hot water , then mix the pre-wetted machine head ash with 0.1% sodium hexametaphosphate solution, and make the solid-to-liquid ratio 1:8, and then use the high-strength shear stirring equipment with ultrasonic dispersion and dissolution function at 55 Keep warm at ℃ for 1 hour. After cleaning, the plate and frame are used for solid-liquid separation, and the filter cake is washed twice with clean water through the plate and frame backwash, finally completing the impurity removal, washing and salt purification of the machine head ash. The contents of main elements in the machine head ash before and after impurity removal and washing salt treatment are shown in Table 1.

[0060] Table 1 The content of main...

specific experiment example 2

[0063] The gas ash from a steel plant is fed to the mixing equipment through a closed belt, and a closed feeding spray system is used at the place where it enters the mixing equipment, and it is pre-wetted with 25°C hot water, and then the pre-wetted gas ash is Mix with 0.1% sodium hexametaphosphate solution to make the solid-liquid ratio 1:3, and use ultrasonic dispersion and high-strength shear force stirring system to keep warm at 25°C for 2 hours, and use the plate frame for solid-liquid separation after cleaning , the filter cake is washed twice with clean water through plate and frame backwashing, and finally the impurity removal, washing and salt purification of gas ash is completed. The contents of main elements in the gas ash before and after impurity removal and washing salt treatment are shown in Table 2.

[0064] Table 2 The content of main elements before and after the treatment of impurity removal and salt washing in a steel plant gas ash / %

[0065] p...

specific experiment example 3

[0067] The machine head ash from a steel plant is fed through a closed belt to a high-strength shear mixing equipment with ultrasonic dispersion and dissolution functions. Spray equipment is used at the place where it enters the mixing equipment, and a solution containing a surfactant at 55 ° C is used to clean it. Carry out pre-wetting, the quality of the solution containing surfactant is 2.0 times of the machine head ash; then mix the pre-wetted machine head ash with 0.05% water glass solution, and make the solid-liquid ratio 1:10, Afterwards, use a high-strength shear stirring device with the function of ultrasonic dispersion and dissolution to keep warm at 95°C for 0.5h. After cleaning, use a plate frame for solid-liquid separation. The filter cake is washed twice with clean water through the plate frame backwash, and finally complete Cleaning, washing and salt purification of machine head ash. The contents of main elements in the machine head ash before and after impurity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com