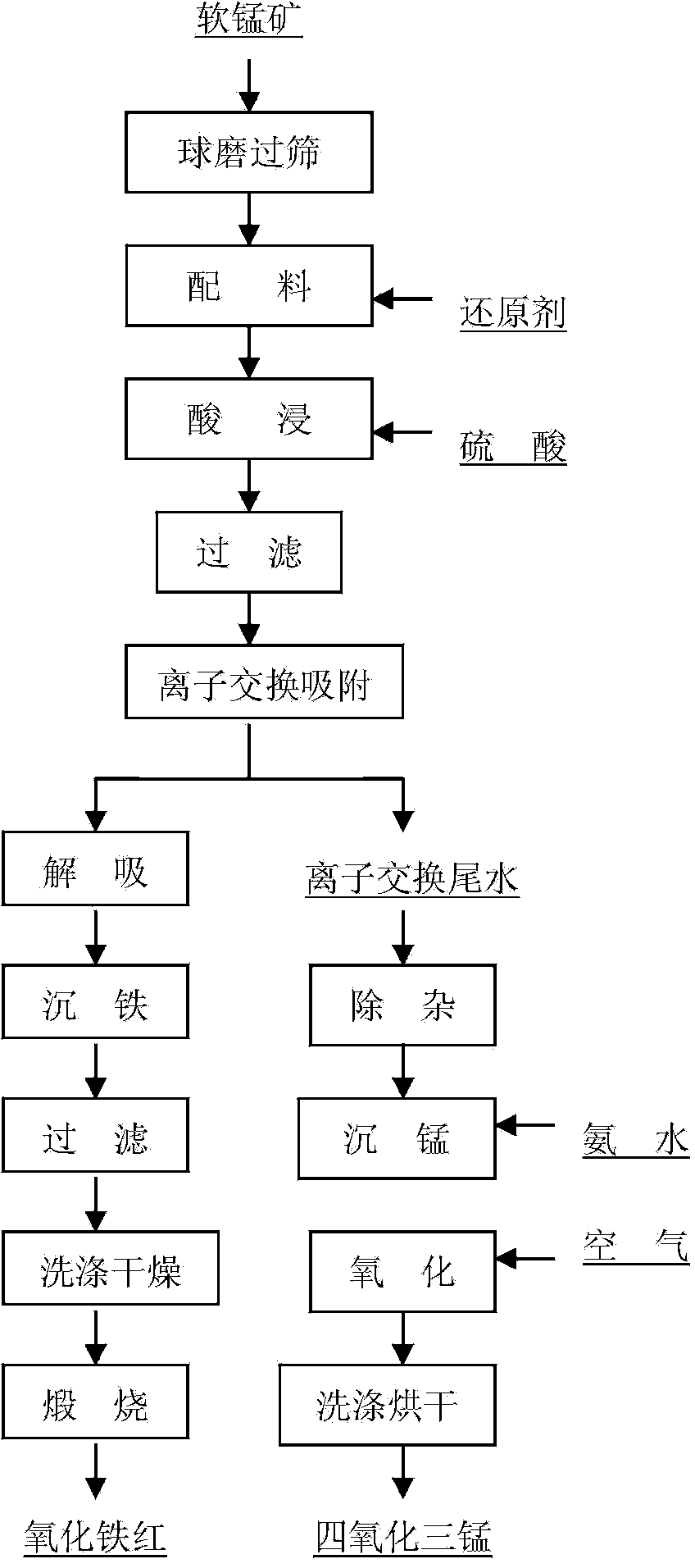

Process for preparing electronic grade manganous-manganic oxide and byproduct nano-iron oxide red from pyrolusite

A technology of trimanganese tetraoxide and red iron oxide, applied in the field of manganese hydrometallurgy, can solve the problems of low manganese leaching rate, environmental pollution, low metal recovery rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Ball-mill the pyrolusite to 80 mesh and then sieve it. Add iron filings as a reducing agent to the sifted material and stir evenly. The amount of iron filings added makes the molar ratio of manganese and iron in the pyrolusite 1.5:1. . The obtained mixed mineral powder is metered into an acid leaching tank, and sulfuric acid with a concentration of 80wt% equivalent to 60% of the mixed mineral powder weight is added. Then, add water, and control the addition of the amount of water according to the solid-to-liquid ratio of 1:6. Stirring and leaching at 80° C. for 5 h, and then separating by filtration to obtain a filtrate. At first the pH of gained filtrate is adjusted to 2.0 and temperature is kept on 38-40 ℃, then this filtrate is adsorbed (reaching equilibrium in 100 minutes) with the adsorption resin A of absorbing iron (Ⅲ), and aqueous phase and adsorption resin phase are separated, obtain Tail water containing manganese and adsorption resin phase containing iron (...

Embodiment 2

[0052] Example 1 was repeated. Other conditions are as follows:

[0053] According to the above steps of ball mill sieving, batching, acid leaching, ion exchange, impurity removal, manganese precipitation, oxidation, washing, drying and other steps, in the batching process, choose pyrolusite with a manganese grade of 35.8% and iron-containing 95.6% scrap iron scrap is used as raw material, and the molar ratio of manganese substance in pyrolusite to iron substance in reducing agent is 1.4:1. The leaching rate of manganese reaches 98.6%, and the comprehensive recovery rate of manganese is 92.5%, the manganese content in the trimanganese tetraoxide product is 71.5%, and the specific surface area is 23.6m 2 / g, selenium-free, silicon dioxide content is 0.005%, sulfur content is 0.032%, the content of ferric oxide in the nano-iron red product is 98.0%, and the particle size is 80nm.

Embodiment 3

[0055] Repeat embodiment 1, wherein use propylene glycol to replace xylitol, other conditions are as follows:

[0056] According to the above steps of ball mill sieving, batching, acid leaching, ion exchange, impurity removal, manganese precipitation, oxidation, washing, drying and other steps, in the batching process, choose pyrolusite with a manganese grade of 27.5% and iron-containing 93.6% of waste iron chips are used as raw materials, and the molar ratio of the amount of manganese in the pyrolusite to the amount of iron in the reducing agent is 1.5:1. The leaching rate of manganese is 98.5%, and the comprehensive recovery rate of manganese is 91.8%, the manganese content in the manganese tetraoxide product is 71.6%, and the specific surface is 22.8m 2 / g, no selenium, silicon dioxide content of 0.006%, sulfur content of 0.038%, iron oxide content of 98.6% in the nano-iron red product, particle size of 90nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com