Cold hydrogenation wet-process dust removal slag slurry discharging system and method

A technology of wet dedusting and cold hydrogenation, applied in the direction of silicon halides, halosilanes, etc., can solve the problems of system shutdown, inability to shut down, loss of system liquid volume, etc., to improve system stability, reduce flow rate, and prolong service life and sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

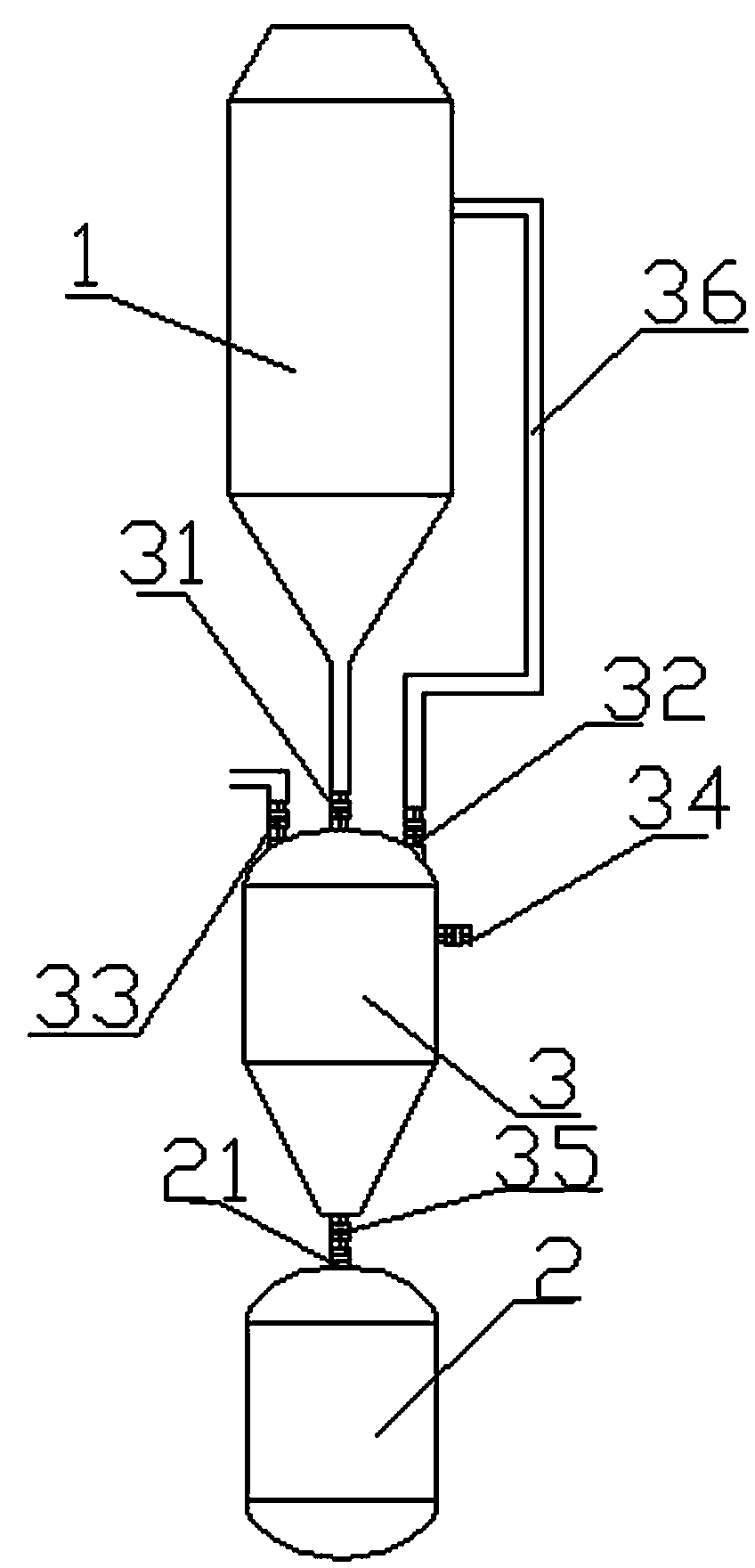

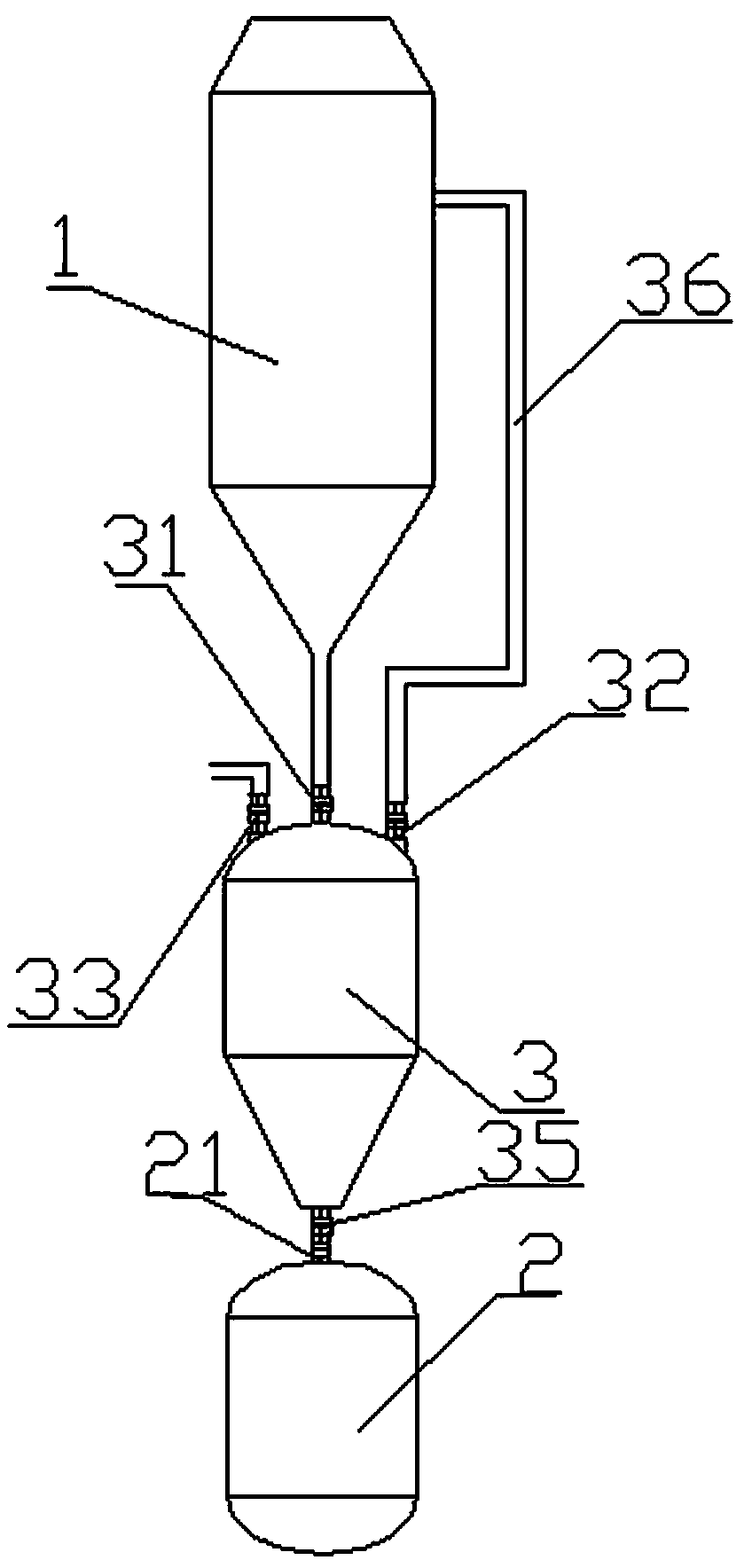

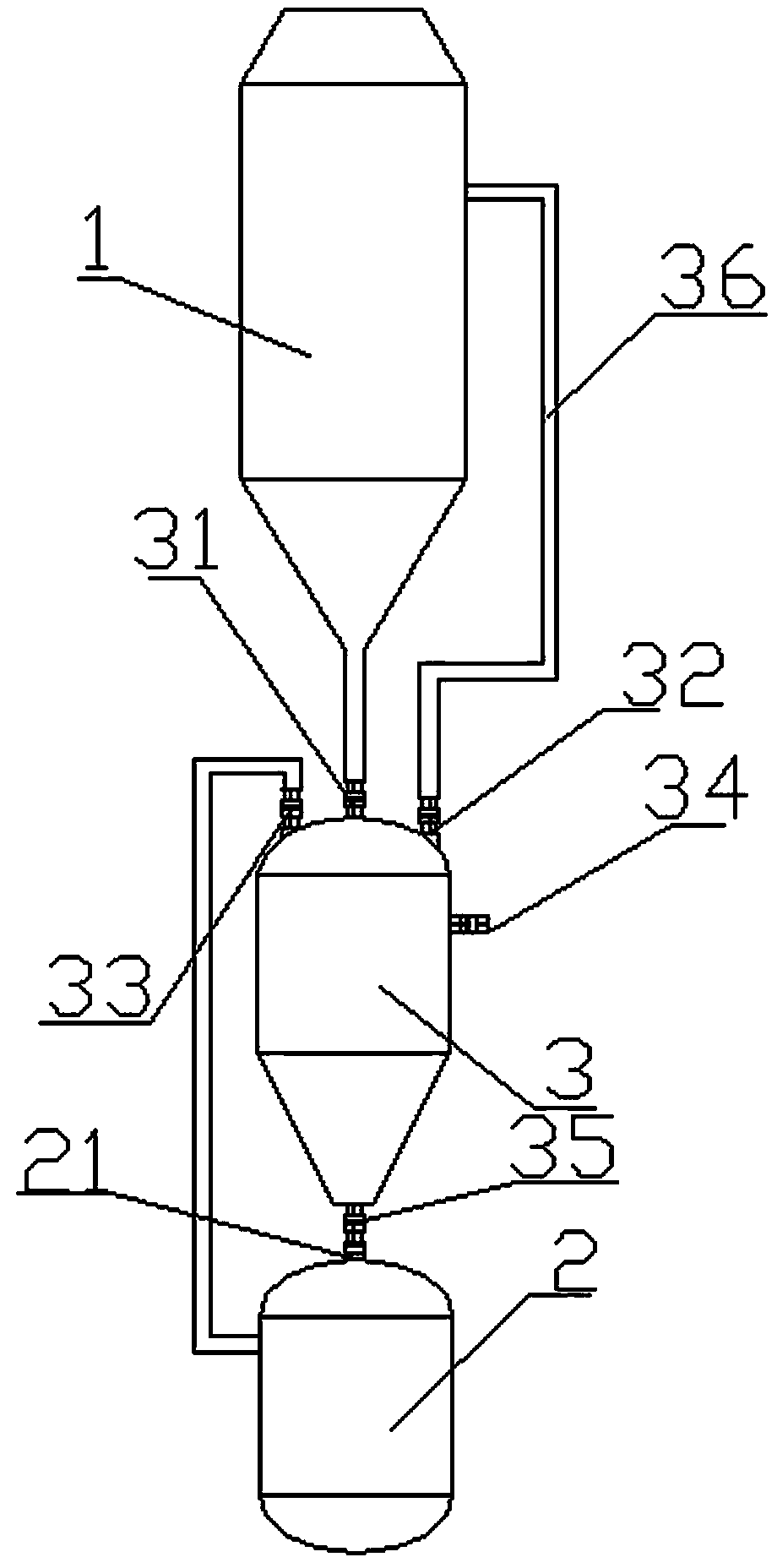

[0031] As a preferred embodiment of the present invention, with reference to the attached figure 2 , the present invention includes a washing tower 1 and a slurry treatment device 2, and is characterized in that: it also includes a slurry receiving tank 3, and the slurry receiving tank 3 is arranged between the washing tower 1 and the slurry treatment device 2; the slag The top of the slurry receiving tank 3 is provided with a slurry inlet valve 31, and the slurry inlet valve 31 is fixedly connected to the bottom of the washing tower 1; the top of the slurry receiving tank 3 is also provided with a balance valve 32 and a vent valve 33; The valve 32 is connected with one end of the balance pipeline 36, and the other end of the balance pipeline 36 is connected to the upper part of the washing tower 1; the bottom of the slurry receiving tank 3 is provided with a slurry outlet valve 35; the slurry outlet valve 43 is connected to the slurry receiving port 21 of the slurry treatmen...

Embodiment 2

[0041] As a preferred embodiment of the present invention, with reference to the attached figure 1 and 4 , the present invention includes a washing tower 1 and a slurry treatment device 2, and is characterized in that: it also includes a slurry receiving tank 3, and the slurry receiving tank 3 is arranged between the washing tower 1 and the slurry treatment device 2; the slag The top of the slurry receiving tank 3 is provided with a slurry inlet valve 31, and the slurry inlet valve 31 is fixedly connected to the bottom of the washing tower 1; the top of the slurry receiving tank 3 is also provided with a balance valve 32 and a vent valve 33; The valve 32 is connected with one end of the balance pipeline 36, and the other end of the balance pipeline 36 is connected to the upper part of the washing tower 1; the bottom of the slurry receiving tank 3 is provided with a slurry outlet valve 35; the slurry outlet valve 43 is connected to the slurry receiving port 21 of the slurry tr...

Embodiment 3

[0053] As another preferred embodiment of the present invention, with reference to the attached figure 1 and 4 , the present invention includes a washing tower 1 and a slurry treatment device 2, and is characterized in that: it also includes a slurry receiving tank 3, and the slurry receiving tank 3 is arranged between the washing tower 1 and the slurry treatment device 2; the slag The top of the slurry receiving tank 3 is provided with a slurry inlet valve 31, and the slurry inlet valve 31 is fixedly connected to the bottom of the washing tower 1; the top of the slurry receiving tank 3 is also provided with a balance valve 32 and a vent valve 33; The valve 32 is connected with one end of the balance pipeline 36, and the other end of the balance pipeline 36 is connected to the upper part of the washing tower 1; the bottom of the slurry receiving tank 3 is provided with a slurry outlet valve 35; the slurry outlet valve 43 is connected to the slurry receiving port 21 of the slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com